Do Teflon Seals Require Lubrication

While it is a general practice to lubricate seals before installation, Teflon seals are an exception to this rule in most cases.

General Practice of Lubricating Seals Before Installation

Lubricating seals before installation is a common practice in many industries. The primary purpose of lubricating seals is to reduce friction during installation, prevent damage to the seal or the mating surface, and ensure proper seating of the seal. Lubrication also helps to fill any microscopic irregularities on the sealing surfaces, enhancing the sealing performance.

In most cases, a thin layer of compatible lubricant is applied to the seal and the mating surface before installation. The choice of lubricant depends on the seal material, the application, and the operating conditions. Common lubricants include silicone grease, petroleum jelly, and mineral oil.

Reasons Why Teflon Seals Should Not Be Lubricated

Despite the general practice of lubricating seals, Teflon seals are an exception. In most applications, Teflon seals should not be lubricated before installation.

Teflon’s Non-adhesive Properties and Potential for Lubricant Rejection

Teflon is known for its non-stick and non-adhesive properties. These properties make Teflon an excellent choice for sealing applications where low friction and chemical resistance are required. However, these same properties can also cause issues when lubricants are applied to Teflon seals.

Due to its non-adhesive nature, Teflon may reject the lubricant applied to its surface. The lubricant may not adhere to the seal, leading to an uneven distribution or complete removal of the lubricant during installation. This can result in increased friction, seal damage, or improper sealing.

Risk of Compromised Solvent Resistance and Leakage Issues

Teflon seals are often chosen for their excellent chemical resistance, particularly in applications involving aggressive solvents, acids, or other chemically harsh environments. Applying lubricants to Teflon seals can potentially compromise their solvent resistance.

Some lubricants may react with the process media, leading to seal degradation or leakage issues. The lubricant may also act as a carrier, allowing the process media to penetrate the seal material more easily. This can result in premature seal failure, leakage, or contamination of the process fluids.

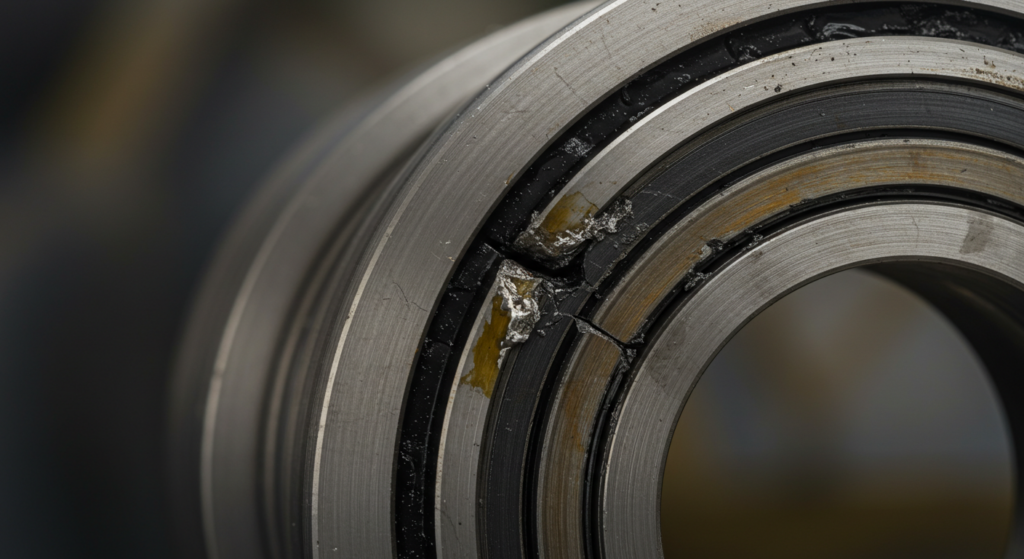

Potential for Seal Shifting or Deformation During Installation

Lubricating Teflon seals can also increase the risk of seal shifting or deformation during installation. Due to the reduced friction between the seal and the mating surface, a lubricated Teflon seal may slide or shift out of position during installation.

This can lead to misalignment, uneven compression, or seal extrusion, compromising the sealing performance and potentially causing leakage issues. In some cases, the deformation may be permanent, requiring seal replacement.

Exceptions and Specific Applications Where Lubrication May Be Necessary

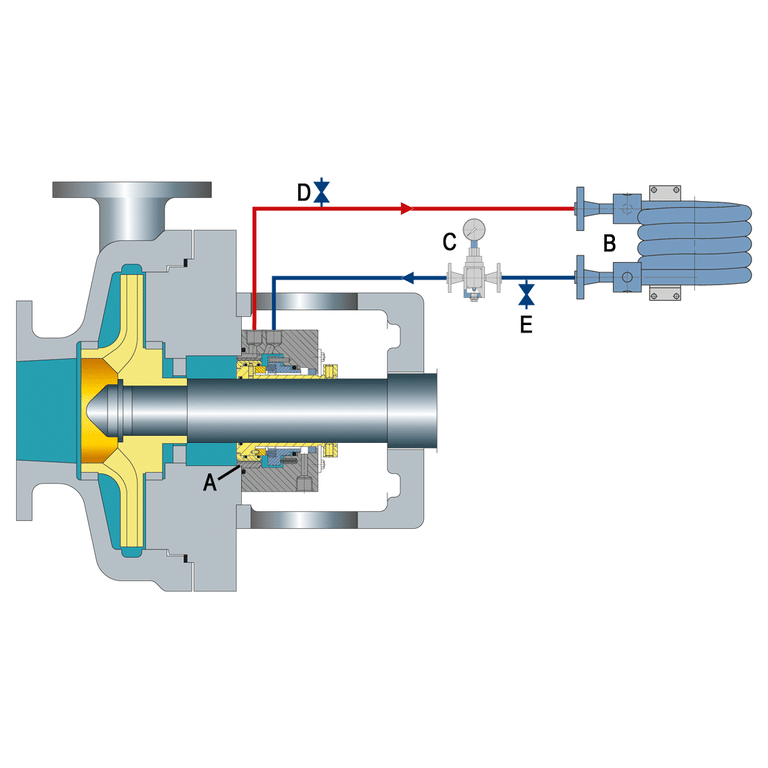

While lubricating Teflon seals is generally not recommended, there are some exceptions and specific applications where lubrication may be necessary. These cases typically involve high-pressure or high-temperature applications, where the lubrication helps to protect the seal from damage during installation or initial operation.

In applications involving high-pressure gasses or liquids, a small amount of compatible lubricant may be applied to the seal to prevent damage from the sudden pressure increase during startup. The lubricant acts as a protective layer, reducing the risk of seal extrusion or cutting.

Similarly, in high-temperature applications, a small amount of high-temperature lubricant may be used to prevent seal damage during the initial thermal expansion. The lubricant helps to reduce friction and allows the seal to slide into its final position without deformation.

When lubrication is necessary for Teflon seals, it is crucial to use a compatible lubricant that does not react with the process media or the seal material. The lubricant should be applied sparingly, ensuring an even distribution without excess.

FAQs

Does oil and water stick on Teflon

Teflon is a non-stick material. Oil and water do not stick to Teflon surfaces.

Can Teflon Be Heat Sealed

Teflon can be heat sealed, but it requires specific conditions. The Teflon surface must be chemically etched first to allow adhesion. Heat sealing is then done at high temperatures around 700°F (371°C).