Mechanical seals are precision components designed to prevent fluid leakage in rotating equipment like pumps. While mechanical seals require a thin film of lubricating fluid to function properly, there may be instances where a seal runs “dry” without this fluid film. In general, most mechanical seals can only withstand dry running for a matter of seconds to a few minutes before significant damage occurs.

Factors Influencing Dry Run Time

Seal Design and Materials

The design and materials used in a mechanical seal significantly impact its ability to run dry without damage. Seals made from harder, more wear-resistant materials like silicon carbide can tolerate dry running for longer periods compared to softer materials like carbon graphite. The seal face geometry, such as the balance ratio and face flatness, also influences dry running capability.

Operating Conditions

Factors such as shaft speed, pressure, and temperature affect how long a seal can survive without lubrication. Higher speeds generate more heat and wear, reducing dry run time. Increased pressure forces the seal faces together more tightly, causing greater friction and heat build-up. Extreme temperatures, both high and low, can degrade seal materials faster during dry operation.

Fluid Properties

The fluid being sealed plays a role in determining dry run endurance. Low-viscosity fluids provide less lubrication and cooling than higher-viscosity ones. Abrasive particles or corrosive chemicals in the fluid accelerate wear and damage to dry-running seal faces. Fluids with good boundary lubrication properties can extend the time a seal withstands running dry.

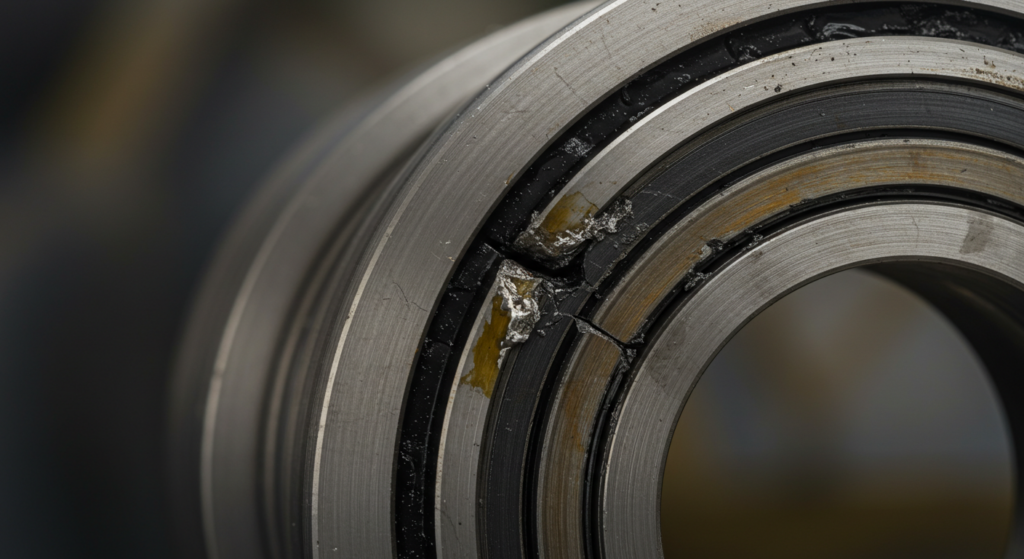

Seal Face Deflection

Dry running causes thermal distortion and uneven wear of the seal faces. This leads to face deflection, where the faces are no longer flat and parallel. Excessive deflection causes the seal faces to open up, allowing leakage. The amount and rate of deflection depend on factors like the seal face materials, balance ratio, and pressure velocity (PV) value. Seals with faces that minimize deflection can maintain sealing effectiveness longer during dry operation.

Consequences of Dry Running

- Rapid seal face wear: Without proper lubrication, the seal faces will experience accelerated wear, leading to increased leakage and reduced seal life.

- Thermal damage: Friction-generated heat can cause thermal damage to the seal faces, secondary seals (O-rings), and other components, leading to premature failure.

- O-ring damage: Overheating can cause the O-rings to harden, lose elasticity, or even melt, compromising the seal’s ability to contain the process fluid.

- Equipment damage: Prolonged dry running can cause damage to the equipment itself, such as shaft scoring, bearing failure, or cavitation in pumps.

- Increased maintenance: Premature seal failure due to dry running leads to more frequent seal replacements and increased maintenance costs.

- Cavitation: In pumps, dry running can cause cavitation, which occurs when the fluid vaporizes and forms bubbles that collapse, creating shock waves that can damage the pump components.

Preventing Dry Running

- Proper Lubrication: Ensuring an adequate supply of clean lubricating fluid to the seal faces. This includes proper sizing and maintenance of seal piping plans.

- Seal Support Systems: Use of seal support systems like API Plan 53B (barrier fluid circulated by pumping ring) or Plan 54 (external barrier fluid system) provides additional lubrication and cooling to maintain a fluid film between the faces.

- Monitoring and Alarms: Installing sensors and alarms to monitor for abnormal seal chamber pressure, temperature, and vibration allows for early detection of off-design operation that could lead to dry running.

- Proper Installation: Careful seal installation following manufacturer instructions and industry best practices helps ensure optimal seal performance and life. Misalignment, improper setting of spring compression, and incorrect piping can all contribute to premature seal failure and dry running.

- Operating at Best Efficiency Point (BEP): Running the equipment at or near its BEP reduces loads and vibration on the seal, extending its overall life and dry run survivability. Avoid operating far from BEP, especially on the low flow side of the curve.

- Maintaining Negative Pressure: Adjust process conditions as feasible to maintain a lower pressure in the seal chamber compared to the suction, ensuring fluid flows toward the seal faces instead of awhile from them during dry operation.

- Considering Chemical Compatibility: Select seal face materials that are chemically compatible and non-reactive with the sealed fluid. Some material combinations can undergo tribochemical reactions when running dry that rapidly degrade the faces.

- Regular Maintenance: Periodic inspection, cleaning, and replacement of seal components based on a preventive maintenance plan keeps the seal in optimal working condition. Identifying excess face wear or defects before failure can prevent unexpected dry running.

- Operator Training: Thoroughly train operators on the correct procedures for seal operation, troubleshooting and when to shut down equipment if dry running is suspected. Include seal failure and dry run prevention in operating procedures and checklists.