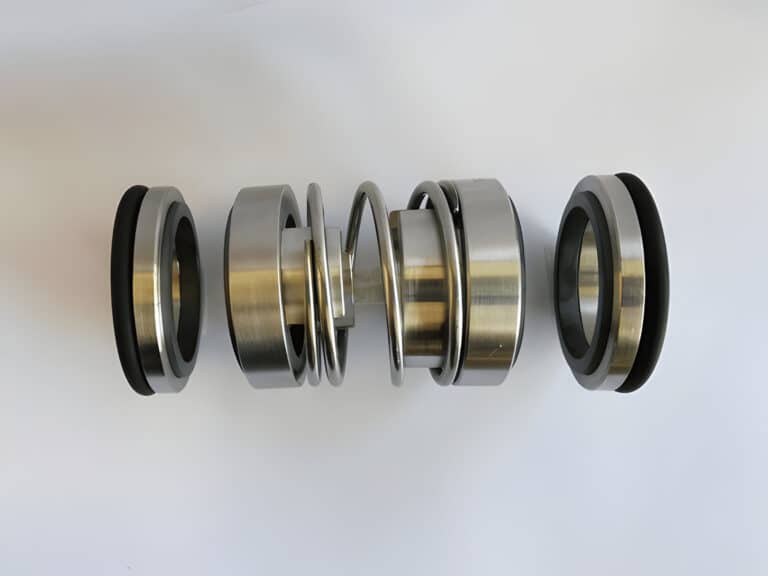

Cartridge mechanical seals come in four main types: single, double (pressurized), tandem (unpressurized), and split designs.

Single seals use one set of faces and work well for basic applications. Double seals have two sets of faces with pressurized fluid between them for zero leakage. Tandem seals also have two sets but use unpressurized buffer fluid for backup protection. Split seals come apart in halves for easy installation on large equipment.

Each type serves different needs based on safety requirements, fluid properties, and maintenance considerations.

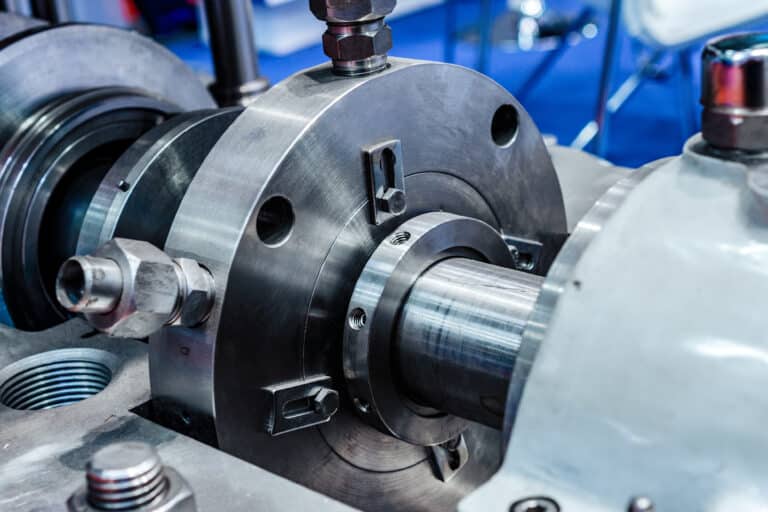

Single Cartridge Seals

Single cartridge seals are the simplest and most common type. They contain one rotating face and one stationary face that slide against each other to prevent leaks.

The seal works by maintaining a microscopic film of fluid between the two faces. This film provides lubrication and cooling. Springs push the faces together while the fluid film keeps them from touching directly.

These seals handle general-purpose pumping well. Water pumps, coolant systems, and non-hazardous chemicals all use single seals effectively.

The main advantage is simplicity. Single seals cost less and install quickly. They need minimal support equipment and take up little space.

However, single seals always leak slightly. This small amount of vapor or drips is normal and necessary for face lubrication. They cannot handle toxic or dangerous fluids safely. If the seal fails, there’s no backup to prevent a major leak.

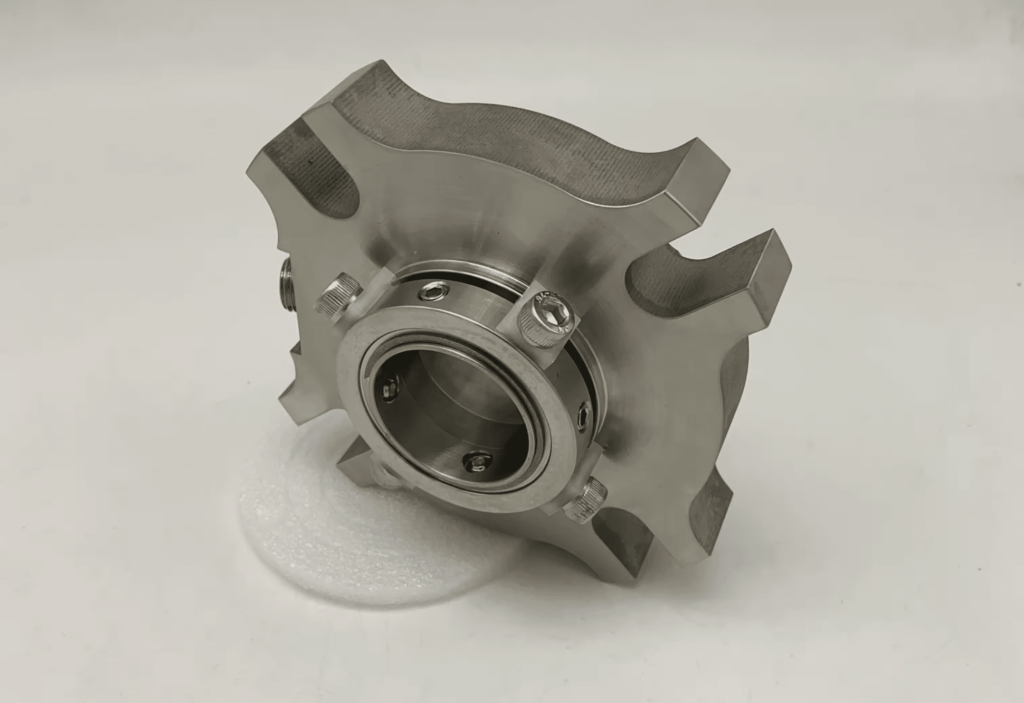

Double Cartridge Seals (Dual Pressurized)

Double cartridge seals provide maximum safety by using two complete seal sets with pressurized barrier fluid between them. The barrier fluid pressure stays higher than the process pressure, creating a protective zone that prevents any process fluid from escaping.

This design eliminates process leakage completely. If the inner seal wears, only clean barrier fluid enters the pump. If the outer seal fails, only barrier fluid leaks out, not the dangerous process fluid.

Chemical plants use double seals for toxic materials like benzene and acids. Refineries rely on them for volatile organic compounds. Any application with strict emission regulations needs this level of protection.

The seal faces last longer because they only contact clean barrier fluid, not the harsh process. This is especially helpful with abrasive or hot fluids that would quickly destroy single seals.

Back-to-Back

Back-to-back arrangements position the rotating seal rings facing away from each other. This configuration works well when axial space is limited.

The design creates a compact assembly that fits standard seal chambers. Both sets of springs sit between the faces, making maintenance access easier.

Many older pumps upgrade to back-to-back double seals without modifications. The arrangement handles moderate pressures effectively while maintaining good face cooling.

Face-to-Face

Face-to-face designs place the rotating rings facing toward each other. This arrangement excels at high-pressure applications.

The configuration balances hydraulic forces better than back-to-back designs. Face-to-face seals can handle extreme pressures that would overwhelm other arrangements.

However, they require more axial space. The design also makes spring replacement more difficult since they’re on opposite ends of the assembly.

Tandem Cartridge Seals (Dual Unpressurized)

Tandem seals mount two single seals in series with unpressurized buffer fluid between them. The primary seal does all the work while the secondary seal stands ready as backup.

During normal operation, the primary seal contains the process just like a single seal would. Any small leakage goes into the buffer chamber, not the atmosphere. The secondary seal only sees clean buffer fluid and essentially idles along.

If the primary seal fails, the secondary immediately takes over. This gives operators time to shut down safely without a dangerous leak.

The buffer system is simpler than pressurized barriers. A basic reservoir at atmospheric pressure is enough. There’s no need for high-pressure pumps or complex controls.

Split Cartridge Seals

Split seals divide into two halves that wrap around the shaft. This design allows installation without taking equipment apart.

Each half contains precisely machined seal components that align perfectly when joined. Special pins and keys ensure proper positioning. Modern split seals achieve performance nearly equal to one-piece designs.

Large vertical pumps benefit most from split seals. Removing a motor and pump head normally takes days with cranes and multiple workers. A split seal installs in hours with basic tools.

Split seals cost more initially but pay back through reduced downtime.

The main limitation is the split joints themselves. These create potential leak paths that need careful sealing. Installation must follow procedures exactly to prevent problems.

Most plants avoid split seals for extremely hazardous fluids. The slight extra leak risk from the joints makes them better suited for water, slurry, and less dangerous services.