Metal bellow mechanical seals solve one of the biggest headaches in rotating equipment: seal hangup. If you’ve ever dealt with a pump that keeps leaking because the dynamic O-ring stuck to the shaft, you’ll understand why engineers get excited about these seals. They eliminate that sliding elastomer completely.

These seals use a flexible metallic bellows instead of the springs and O-rings found in traditional pusher seals. The bellows acts as both the spring element and the secondary seal in one component. That’s the key difference that makes them work in conditions where conventional seals fail.

I’ve seen facilities switch to metal bellows seals after burning through pusher seals every few months in high-temperature services. The result? Run times measured in years, not weeks.

In this guide, you’ll learn exactly how these seals work, when to specify them, and how to choose the right type for your application.

How Do Metal Bellows Mechanical Seals Work?

Metal bellows seals maintain a thin fluid film between two precision-lapped faces while the bellows flexes to accommodate shaft movement. The design is elegant in its simplicity: no sliding parts that can stick, fret, or hang up.

What Are the Key Components?

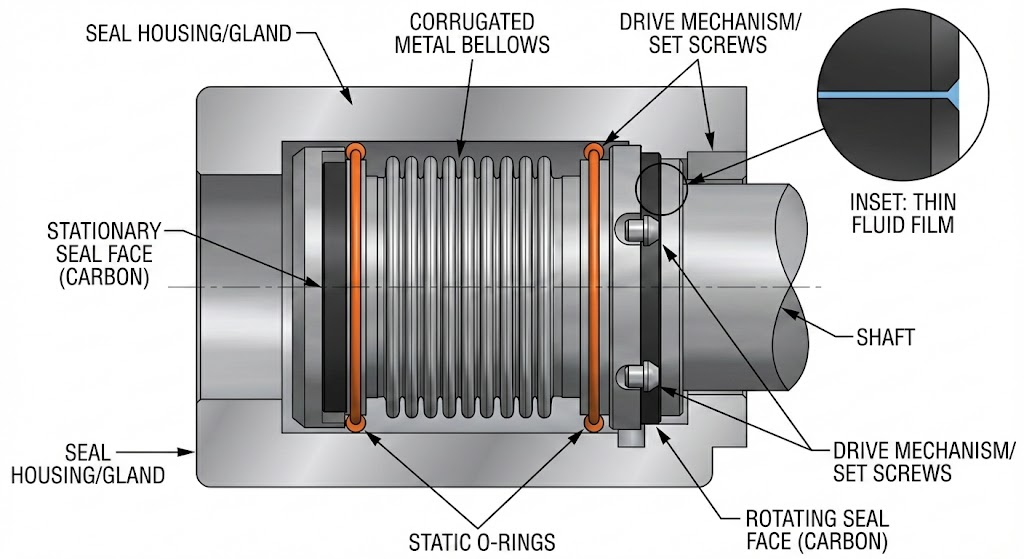

A metal bellows seal has five main components that work together:

The metal bellows is the heart of the seal. It’s a flexible, corrugated metal tube made from thin diaphragms welded together. This bellows does double duty. It provides the spring force that keeps the seal faces together, and it acts as the secondary seal between the rotating and stationary parts. Most bellows use plates only 0.004 inches thick.

The stationary seal face sits fixed in the seal housing. It’s typically made from silicon carbide or tungsten carbide because these materials can handle the heat and wear at the sealing interface.

The rotating seal face attaches to the shaft and spins with it. Carbon graphite is the most common material here. It pairs well with the harder stationary face and provides some self-lubricating properties.

Static O-rings and gaskets seal the points that don’t move. These are the connections between the seal components and the pump housing or shaft.

The drive mechanism transfers torque from the shaft to the rotating seal components. This keeps everything spinning together without slipping.

How Does the Sealing Mechanism Function?

The sealing action happens between the two lapped faces. Here’s how it works, step by step:

Step 1: Creating the Seal

When you install the seal and pressurize the system, the fluid pressure acts on the effective area of the bellows. This hydraulic force, combined with the mechanical spring force of the bellows itself, pushes the rotating face against the stationary face.

Step 2: Forming the Fluid Film

A microscopic film of process fluid forms between the faces. This film is essential. It lubricates the interface and carries away heat. Without it, the faces would run dry and fail within minutes.

Step 3: Compensating for Movement

As the equipment runs, the shaft moves. It experiences thermal expansion, vibration, and slight misalignment. The bellows flexes to absorb all this movement while maintaining constant face loading. Traditional seals need a sliding O-ring to do this. The bellows handles it without any sliding contact.

Step 4: Self-Adjusting Operation

The bellows continuously adjusts throughout operation. If the shaft moves axially, the bellows compresses or extends. If there’s angular misalignment, it flexes to compensate. The seal faces stay in contact with consistent pressure regardless of these movements.

This continuous self-adjustment is why metal bellows seals excel in applications with shaft runout, thermal cycling, or vibration. The system adapts automatically.

What Are the Different Types of Metal Bellows Seals?

Metal bellows seals come in two primary construction types: edge-welded and formed. The choice between them depends on your operating conditions and budget.

Edge-Welded vs Formed Bellows: Which Should You Choose?

Edge-welded bellows outperform formed bellows in nearly every measurable way, but they cost more. Here’s how they compare:

| Feature | Edge-Welded Bellows | Formed Bellows |

|---|---|---|

| Manufacturing | Individual diaphragms welded at alternating edges | Tubing shaped by hydraulic pressure or rolling |

| Material Options | Stainless steel, Inconel, Hastelloy, titanium | Limited to high-elongation metals (brass, bronze) |

| Flexibility | Highest (thin diaphragms in mils) | Lower (thicker walls) |

| Temperature Range | Cryogenic to over 1000°F | Much narrower range |

| Spring Rate | Precisely controllable | Higher and less consistent |

| Pressure Capability | Superior | Moderate |

| Cost | Higher per unit | Lower when mass-produced |

| Best Applications | Oil & gas, aerospace, power generation | General industrial, moderate-duty |

My recommendation: If you’re working in petrochemical, power generation, or any demanding environment, specify edge-welded bellows. The performance difference justifies the cost premium. I’ve seen formed bellows fail repeatedly in refinery services where edge-welded designs ran for years.

Formed bellows make sense for water pumping, HVAC systems, and other moderate applications where you need a bellows seal but don’t face extreme conditions.

When Should You Use Single-Ply vs Double-Ply Bellows?

Single-ply bellows work for most standard applications. They’re simpler, more flexible, and cost less.

Double-ply bellows use two layers of thin metal instead of one. This gives you higher strength without the stiffness penalty you’d get from using thicker single-ply material. The spring rate of a two-ply bellows is significantly lower than a single-ply bellows of equivalent thickness.

Choose double-ply when you need:

- Higher pressure capability (up to 1000 psi)

- Services with thermo-sensitive fluids that might solidify

- Applications requiring more start-up torque

The double-ply construction handles pressures up to 1000 psi, compared to around 360 psi for standard single-ply designs.

What Are the Operating Limits and Specifications?

Metal bellows seals handle conditions that would destroy conventional seals. But they do have limits you need to respect.

Temperature, Pressure, and Speed Ratings

| Parameter | Standard Rating | Extended Rating | Notes |

|---|---|---|---|

| Temperature | -100°F to 800°F | Up to 850°F with graphite packing | Operate at 80% of max for longevity |

| Pressure | Vacuum to 360 psi | Up to 1000 psi (double-ply) | Some designs handle 500 psi without shaft step |

| Speed | Up to 5000 fpm | Varies by design | Check manufacturer specs |

Temperature considerations:

The bellows itself isn’t usually the limiting factor for temperature. The secondary sealing elements determine your upper limit:

- VITON O-rings: Below 200°C (392°F)

- FFKM (perfluoroelastomer): 200-260°C (392-500°F)

- Flexible graphite: Beyond 260°C (500°F), up to 425°C (800°F)

For the highest temperature services, you’ll use flexible graphite throughout. This eliminates elastomers entirely.

How Do You Select the Right Bellows Material?

Material selection makes or breaks metal bellows seal performance. The bellows material must resist corrosion from your process fluid while maintaining its mechanical properties at operating temperature.

Which Alloy Is Best for Your Application?

| Material | Temperature Capability | Corrosion Resistance | Cost | Best For |

|---|---|---|---|---|

| SS 316/316L | Moderate | General | $ | Standard applications, non-corrosive fluids |

| AM350 | Good | Good | $$ | Refinery services, cost-conscious projects |

| Inconel 718 | Excellent | Excellent | $$$ | Aerospace, chemical, petroleum, high-temp |

| Hastelloy C | Excellent | Superior | $$$$ | Hot acids, alkalis, chlorinated solvents |

| Titanium | Good | Excellent | $$$$ | Aerospace, marine, weight-critical |

Selection guidelines:

For clean, non-corrosive thermal fluids, SS316 with silicon carbide faces provides excellent value. This covers most water-based systems and mild process fluids.

For refinery applications, AM350 offers good performance at reasonable cost. It handles most hydrocarbon services well.

For corrosive chemicals at high temperatures, you’ll need Inconel 718 or Hastelloy C. Inconel 718 has stronger corrosion resistance than AM350 and actually hardens over time, becoming more durable with use. That’s why it’s widely specified in both petroleum and chemical industries.

For aggressive environments like hot acids, alkalis, and chlorinated solvents, Hastelloy C is the standard. Pumps handling these fluids benefit from the corrosion resistance of Hastelloy C bellows paired with tungsten carbide seal faces.

What Seal Face Materials Should You Specify?

The seal faces experience the most demanding conditions in the seal. They must withstand friction, heat, and chemical attack while maintaining flatness measured in millionths of an inch.

Premium carbon graphite handles most services. Look for blister-resistant grades that won’t degrade when trace moisture in the carbon encounters high temperatures. API 682 specifies this as the standard face material.

Silicon carbide provides excellent hardness and wear resistance. Reaction-bonded and self-sintered grades offer different properties. Self-sintered silicon carbide is harder and more chemically resistant but more brittle.

Tungsten carbide is the hardest face material option. It’s specified for abrasive services or when both faces need to be hard materials.

Material pairing matters: The standard pairing is carbon against silicon carbide. This combination offers good lubrication and heat dissipation. For extremely demanding services, you might run silicon carbide against silicon carbide, but this requires better lubrication and generates more heat.

Choosing the Right Metal Bellows Seal

Metal bellows mechanical seals solve real problems that plague conventional seals: hangup, fretting, limited temperature range, and chemical incompatibility. They achieve this by eliminating the dynamic O-ring entirely, using a flexible metal bellows that serves as both spring and secondary seal.

Specify metal bellows seals when you face:

- Temperatures above 150°C (300°F)

- Fluids that coke, crystallize, or leave deposits

- Chemical environments that attack elastomers

- Applications where maintenance access is difficult or expensive

- Critical services where reliability justifies higher initial cost

Key selection decisions:

- Edge-welded bellows for demanding services, formed bellows for moderate duty

- Single-ply for standard applications, double-ply for high pressure

- Alloy selection based on process chemistry (SS316 for mild, Inconel 718 or Hastelloy C for aggressive)

- API 682 compliance for petroleum, gas, and chemical industry applications

When you need a seal that performs reliably in extreme conditions, metal bellows technology delivers.