What Are Multiple Spring Mechanical Seals

Multiple Spring mechanical seals are a type of mechanical seal that utilizes multiple springs to provide uniform sealing force between the rotating and stationary components of a pump or other rotating equipment.

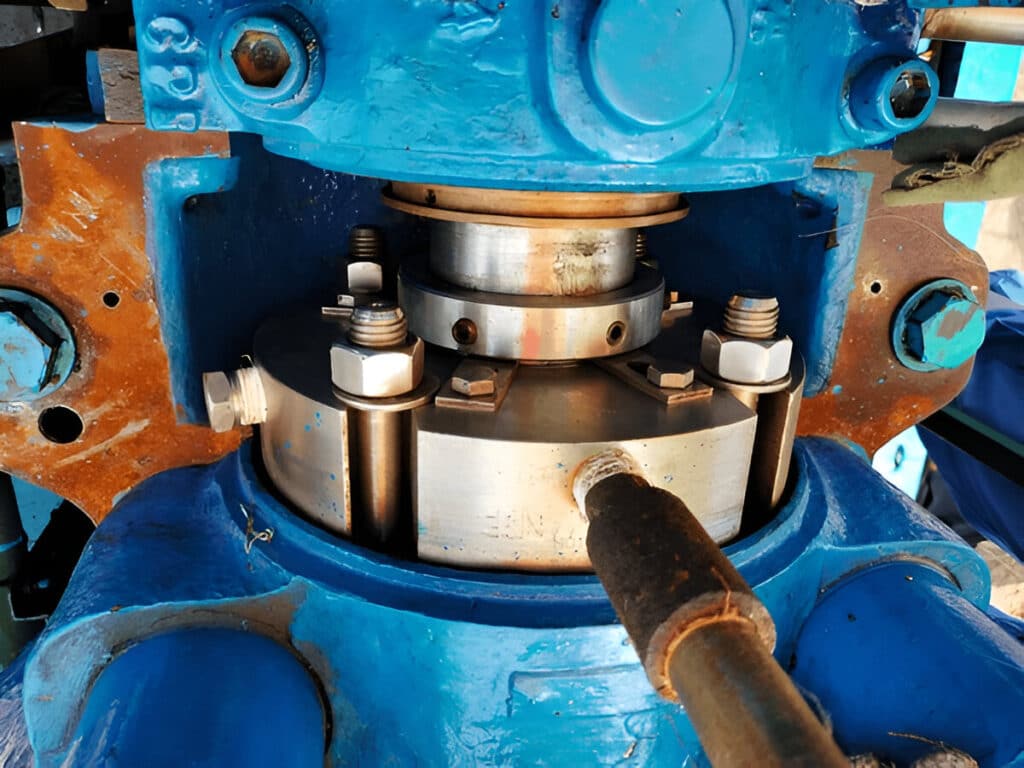

These seals consist of two main parts: a rotating seal ring attached to the shaft and a stationary seal ring mounted in the seal housing. The seal faces are pressed together by the force of the multiple springs, creating a tight seal that prevents fluid leakage.

How Multiple Spring Mechanical Seals Work

Multiple spring mechanical seals consist of a stationary and rotating component, each with a highly polished sealing surface. These surfaces are pressed together by multiple springs, typically arranged in a circular pattern, providing even pressure distribution. The springs compensate for any mechanical or thermal distortion, ensuring constant contact between the sealing faces.

As the shaft rotates, a thin film of barrier fluid is drawn between the sealing surfaces through capillary action. This fluid film, often just a few microns thick, prevents direct contact between the faces, minimizing wear and heat generation. The barrier fluid also helps to lubricate the seal faces and transfer heat away from the sealing interface.

What Is the Purpose of Spring in Mechanical Seal

The primary purpose of the springs in a mechanical seal is to maintain a constant sealing force between the seal faces. This constant force ensures that the seal faces remain in close contact, even under varying operating conditions such as temperature changes, pressure fluctuations, and shaft vibrations.

The springs also help to compensate for any wear that occurs on the seal faces over time. As the seal faces wear, the springs continue to press the faces together, maintaining the sealing performance of the mechanical seal.

Advantages of Multiple Spring Mechanical Seals

- Consistent sealing force: Multiple spring mechanical seals maintain reliable sealing performance across a wide range of operating pressures, even under fluctuating conditions. The multiple springs distribute the load evenly, enhancing stability and adaptability.

- Increased durability and extended service life: The use of multiple springs reduces stress on individual components, minimizing fatigue and failure risks. This redundancy allows continued function even if one spring fails, providing added reliability.

- Improved heat dissipation: Multiple springs create additional pathways for heat transfer, allowing lower operating temperatures.

- Versatility and customization: Multiple spring mechanical seals can be tailored to meet specific industry and application requirements.

What Are Multiple Spring Mechanical Seals Used for

- Chemical Processing: Multiple Spring mechanical seals are used in pumps and other rotating equipment handling corrosive, toxic, or hazardous chemicals.

- Oil and Gas: These seals are used in pumps, compressors, and other equipment in both upstream and downstream oil and gas operations.

- Power Generation: Multiple Spring mechanical seals are used in pumps and other rotating equipment in power plants, including boiler feed water pumps and cooling water pumps.

- Water and Wastewater Treatment: These seals are used in pumps and other equipment handling water, wastewater, and various treatment chemicals.

- Food and Beverage: Multiple Spring mechanical seals are used in pumps and other equipment handling food products, beverages, and cleaning agents, ensuring sanitary operation and preventing contamination.

What Is the Difference between Single Spring and Multiple Spring Mechanical Seals

The main difference between single spring and Multiple Spring mechanical seals lies in the number of springs used to provide the sealing force.

In a single spring mechanical seal, a single spring, usually a coil spring, provides the sealing force between the seal faces. While this design is simpler and less expensive than Multiple Spring seals, it may not provide as uniform a sealing force, particularly in larger seal sizes.

Multiple Spring mechanical seals, on the other hand, use multiple springs arranged around the circumference of the seal to provide a more uniform sealing force. This uniform force distribution results in improved sealing performance, longer seal life, and greater reliability compared to single spring designs.

Additionally, Multiple Spring mechanical seals can be designed with different spring configurations, such as the number of springs, spring material, and spring load, to optimize performance for specific applications and operating conditions. This flexibility makes Multiple Spring seals more versatile and adaptable than single spring designs.