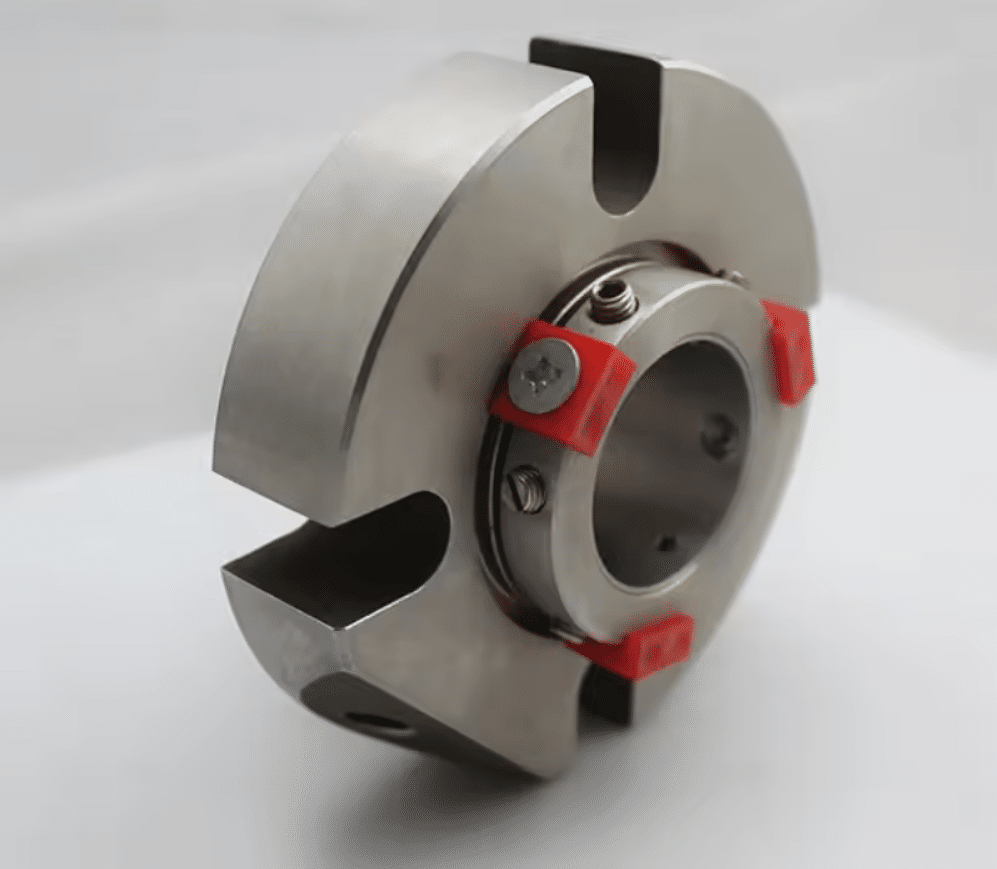

What Is Cartridge Seal

A cartridge seal, also known as a cartridge mechanical seal, is a type of mechanical seal that is designed as a pre-assembled, self-contained unit. This compact, easy-to-install sealing solution consists of a seal head, sleeve, and gland plate, all combined into a single cartridge.

Parts of Cartridge Seal

Gland

The gland is the stationary part of the cartridge seal that is mounted on the equipment’s housing. It serves as the primary connection point between the seal and the equipment. The gland is typically made of a corrosion-resistant material, such as stainless steel, and is designed to withstand the pressure and temperature conditions of the application. It also houses the secondary seals and provides a mounting surface for the seal faces.

Sleeve

The sleeve is the rotating part of the cartridge seal that is mounted on the equipment’s shaft. It is typically made of a hard, wear-resistant material, such as silicon carbide or tungsten carbide. The sleeve is designed to rotate with the shaft and provide a running surface for the seal faces. It also serves as a mounting surface for the springs and other dynamic seal components.

Secondary Seals

Secondary seals, also known as static seals, are used to prevent leakage between the stationary and rotating components of the cartridge seal. They are typically made of elastomeric materials, such as fluoroelastomers (FKM) or perfluoroelastomers (FFKM), and are designed to withstand the chemical and thermal conditions of the application. Common types of secondary seals include O-rings, V-rings, and U-cups.

Seal Faces

The seal faces are the heart of the cartridge seal and are responsible for maintaining a tight seal between the stationary and rotating components. Cartridge seals can have either two or four seal faces, depending on the design and application requirements. The primary seal faces are typically made of a hard, wear-resistant material, such as silicon carbide, tungsten carbide, or carbon graphite. They are precisely lapped and polished to ensure a smooth, flat sealing surface. The secondary seal faces, if present, are usually made of a softer material, such as carbon graphite or PTFE, and provide additional sealing capability.

Springs

Springs are used in cartridge seals to maintain a constant contact pressure between the seal faces, ensuring optimal sealing performance. There are several types of springs used in cartridge seals, including single springs, multiple springs, metal bellows, and elastomers.

- Single springs are the most common type and are typically made of a corrosion-resistant material, such as Hastelloy or Elgiloy.

- Multiple springs are used in applications that require higher sealing pressures or improved dynamic stability.

- Metal bellows are used in high-temperature or high-pressure applications

- Elastomers are used in low-pressure or low-temperature applications.

Lock Collar

The lock collar is a critical component of the cartridge seal that is used to secure the seal assembly to the shaft. It is typically made of a corrosion-resistant material, such as stainless steel, and is designed to grip the shaft tightly without causing damage. The lock collar also provides a means of adjusting the seal face contact pressure during installation and maintenance.