What Is a Rotary Union

A rotary union, also known as a rotary joint, rotary coupling, or swivel joint, is a device that allows the transfer of fluid, such as water, steam, or oil, from a stationary source to a rotating component. Rotary unions enable a continuous, leak-free connection between the stationary and rotating parts of a machine, facilitating the efficient transfer of media while maintaining a high flow rate and prolonged service life.

How Does Rotary Union Work

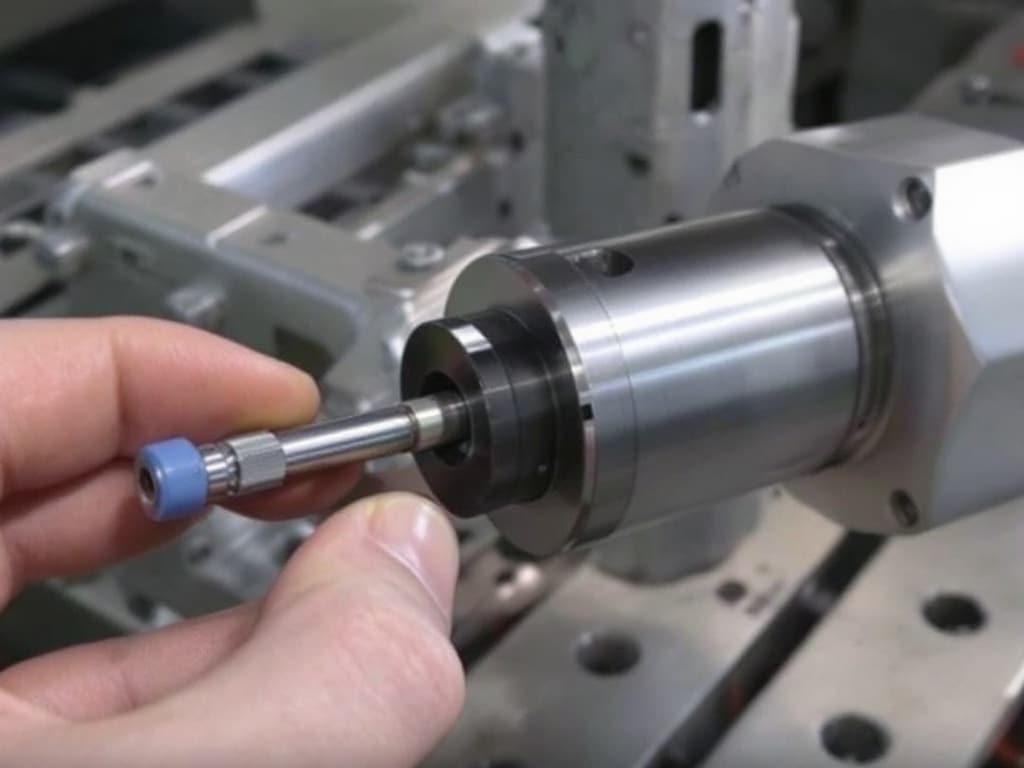

The housing of the rotary union is connected to the stationary supply of the fluid or media. The rotating shaft, which is supported by bearings, such as deep groove ball bearings or angular contact ball bearings, passes through the housing. The shaft is connected to the rotating equipment, such as rolls, drums, or spindles.

The fluid enters the rotary union through the stationary inlet and flows through internal passages in the housing and shaft. The fluid then exits the rotary union through an outlet in the rotating shaft, providing a constant supply of fluid to the rotating equipment.

Function of Rotary Union

The primary function of a rotary union is to facilitate the transfer of fluid, electrical power, or hydraulic power from a stationary source to a rotating component in various industrial applications. Some key functions include:

- Fluid transfer: Rotary unions enable the transfer of fluids such as water, steam, oil, or coolant to rotating equipment, ensuring a continuous supply for processes like cooling, lubrication, or heating.

- Electrical power transfer: Electrical slip rings integrated with rotary unions allow the transfer of electrical power and signals to rotating components, such as in wind turbines or assembly lines.

- Hydraulic power transfer: Hydraulic unions facilitate the transfer of hydraulic fluid to power rotating components in applications such as injection molding or machine tools.

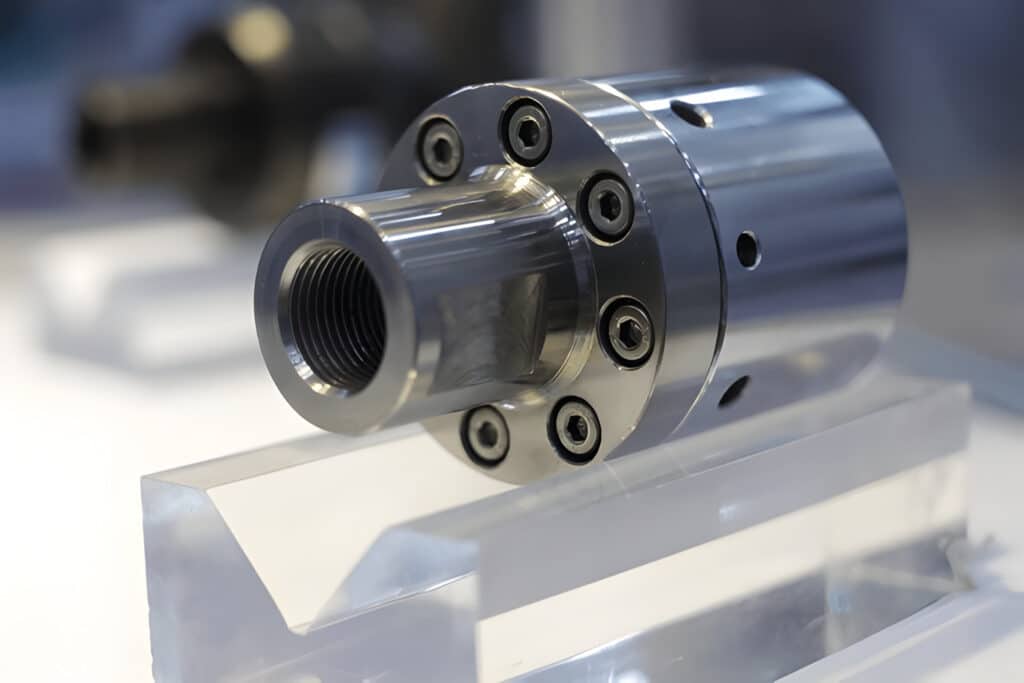

Composition of Rotary Union

Housing

The housing is the outer shell of the rotary union and serves as a protective cover for the internal components. It is typically made from durable materials such as anodized aluminum or stainless steel, depending on the application requirements. The housing also features input holes or an input valve for the stationary inlet of the fluid being transferred.

Shaft

The shaft is the rotating component of the rotary union that connects to the rotating equipment, such as rolls of paper or plastic materials. It is usually made from high-strength materials like hardened steel to withstand the stresses of continuous rotation. The shaft may feature flow passages or channels to allow for the efficient transfer of fluid from the stationary source to the rotating equipment.

Bearing

Bearings are crucial components in a rotary union that support the rotating shaft and ensure smooth, low-friction operation. The most common types of bearings used in rotary unions are deep groove ball bearings and angular contact ball bearings. These bearings are designed to withstand the radial and axial loads imposed by the rotating shaft and the fluid pressure.

Retaining Ring

The retaining ring is a small but essential component that holds the bearing in place within the housing. It prevents the bearing from moving axially and ensures proper alignment of the shaft and housing. Retaining rings are typically made from high-strength materials like spring steel and are available in various sizes and configurations to suit different rotary union designs.

Mechanical Seal

The mechanical seal is a critical component in a rotary union that prevents fluid leakage between the stationary and rotating parts. It consists of two main components: a stationary seal ring and a rotating seal ring. These seal rings are typically made from wear-resistant materials such as silicon carbide, tungsten carbide, or ceramic. The mechanical seal maintains a constant contact pressure between the seal rings, ensuring a leak-free operation even under high-pressure conditions.

Types of Rotary Union

There are several types of rotary unions, each designed for specific applications and operating conditions. Some common types include:

Pressure Joints

Pressure joints are designed for high-pressure applications, such as hydraulic systems or high-pressure water cleaning. They typically feature reinforced housings and specialized seals to withstand extreme pressure.

Plastomeric Seals

Rotary unions with plastomeric seals are suitable for applications involving low to medium pressures and temperatures. These seals are made from materials like PTFE or polyurethane and offer good chemical resistance and low friction.

Hydrostatic Seals

Hydrostatic seals are used in rotary unions for high-speed, high-pressure applications. They utilize a thin film of fluid to create a barrier between the stationary and rotating components, minimizing wear and ensuring a long service life.

Mechanical Seals

Mechanical seals are the most common type of seal used in rotary unions. They consist of two flat surfaces, one stationary and one rotating, that are pressed together to create a leak-free seal. Mechanical seals are available in various materials and configurations to suit different application requirements.

Operating Parameters of Rotary Union

Speed

The rotational speed of the application determines the type of bearings and seals required in the rotary union. High-speed applications may require specialized bearings and seals to minimize wear and ensure a long service life.

Pressure

The operating pressure of the system is a critical factor in selecting the appropriate rotary union. High-pressure applications require rotary unions with reinforced housings and specialized seals to prevent leakage and ensure safe operation.

Temperature

The temperature of the media being transferred and the ambient temperature of the operating environment must be considered when selecting a rotary union. High-temperature applications may require rotary unions with specialized seals and materials to withstand the extreme conditions.

Media Types of Rotary Union

- Water: Rotary unions for water are commonly used in applications such as cooling systems, cleaning equipment, and irrigation.

- Steam: Steam rotary unions are designed to handle high-temperature, high-pressure steam in applications such as power generation, food processing, and chemical manufacturing.

- Oil: Oil rotary unions are used in applications such as lubrication systems, hydraulic power transfer, and cooling systems for machine tools.

- Air: Air rotary unions are used in applications such as pneumatic power transfer, cooling, and drying systems.

- Coolant: Rotary unions for coolant are used in machining and metal cutting applications to provide a continuous supply of coolant to the cutting tool.

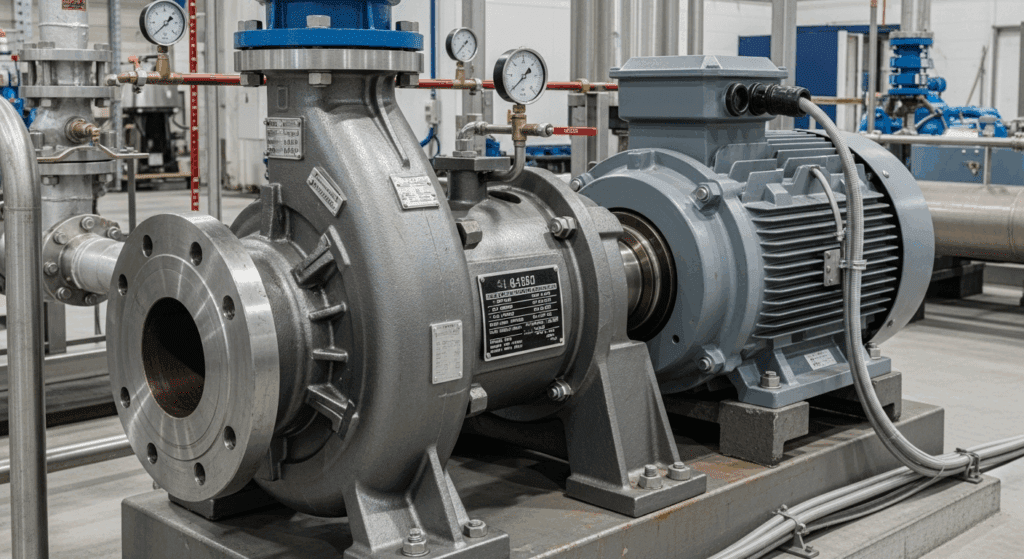

Applications of Rotary Union

- Machine tools: Rotary unions are used in machine tools for the transfer of coolant, lubricant, and hydraulic fluid to rotating components such as spindles and indexing tables.

- Plastic extrusion: Rotary unions are used to transfer cooling water to the extrusion rolls, ensuring precise temperature control and consistent product quality.

- Paper industry: Rotary unions are employed for the transfer of steam, hot oil, and cooling water to drying rolls, calendar rolls, and other rotating components.

- Textiles: Rotary unions are utilized in applications such as dyeing, printing, and finishing, where they transfer steam, hot water, and dyes to rotating drums and rolls.

- Food processing: Rotary unions are used for the transfer of steam, hot water, and cleaning solutions to rotating equipment such as mixers, blenders, and cooking vessels.

- Steel industry: Rotary unions are employed for the transfer of coolant, hydraulic fluid, and lubricant to rotating components in continuous casting machines, rolling mills, and other equipment.

- Energy: Rotary unions are used in wind turbines for the transfer of hydraulic fluid to control blade pitch and in hydroelectric power plants for the transfer of water to turbines.