You’ve seen it in a parts list or maintenance manual: “throttle bush.” Maybe you’re trying to order a replacement, or perhaps you’re just trying to understand what all these seal components do. The terminology can be confusing, especially since there’s another component called a “throat bush” that sounds almost identical.

By the end of this guide, you’ll know exactly what a throttle bush does, where it sits in the seal assembly, and whether your mechanical seal needs one.

What Is a Throttle Bush?

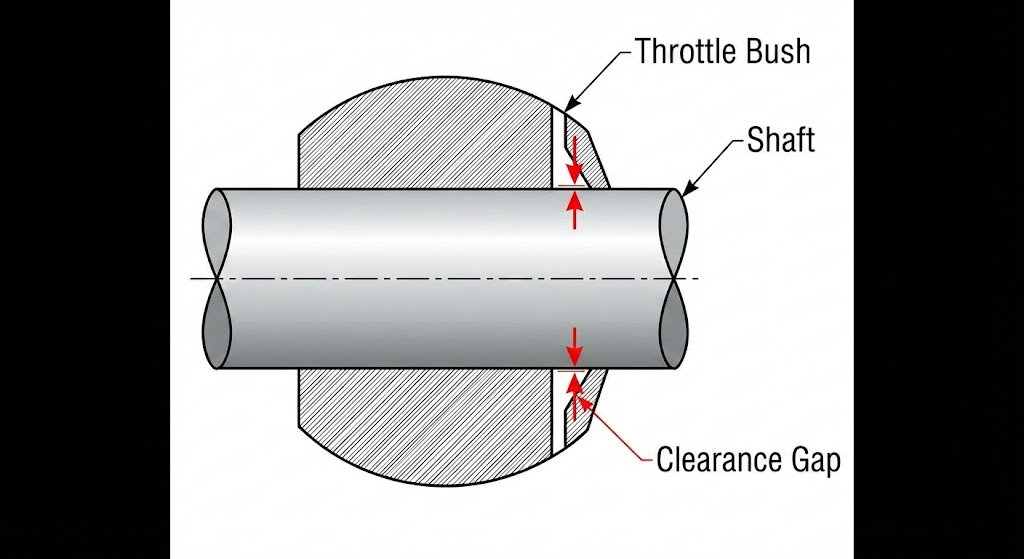

A throttle bush is a small ring-shaped component that creates a narrow gap around the shaft to control fluid flow. Think of it like a partially closed gate – it doesn’t completely stop fluid from passing through, but it restricts how much can get by.

Picture a cylindrical sleeve with a hole just slightly larger than the shaft. That tiny gap between the bush and shaft is the “throttle” – it limits flow and creates a pressure barrier.

Where Is It Located?

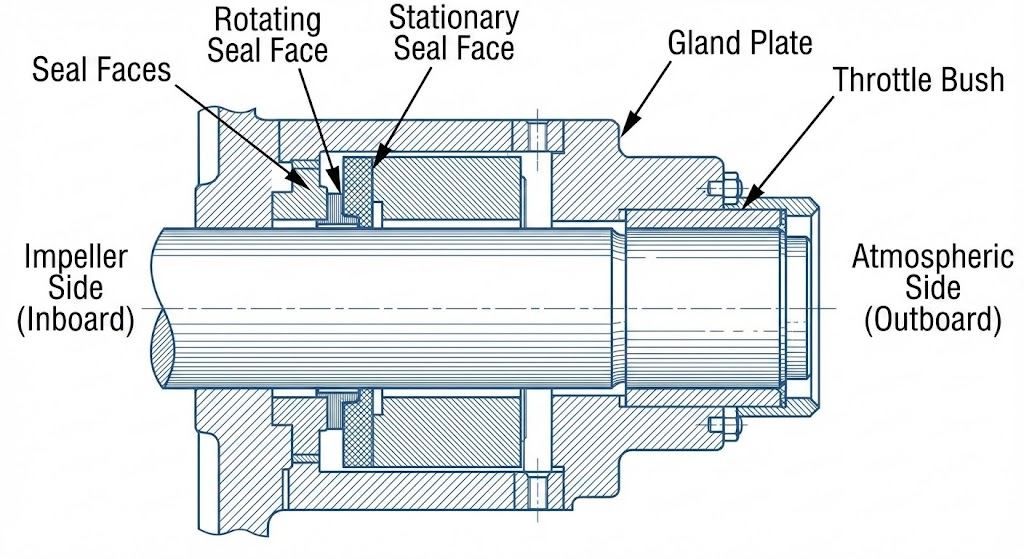

The throttle bush sits on the outboard side of the mechanical seal, meaning the atmospheric end – the side closest to you if you’re looking at the pump from outside.

It connects to the seal gland plate and wraps around the shaft sleeve at the point where the seal assembly meets the outside air. This position is critical because it’s the last line of defense before any leaked fluid reaches the atmosphere.

What Does a Throttle Bush Do?

Primary Functions

The throttle bush serves four key purposes in a seal assembly:

- Contains leakage from the mechanical seal faces

- Creates a restricted clearance to maintain pressure in the seal chamber

- Directs any leaked fluid to drain ports rather than letting it escape freely

- Provides backup containment if the seal faces temporarily open

I recommend thinking of the throttle bush as your seal’s safety net. Even when everything works perfectly, a small amount of fluid vapor passes the seal faces. The throttle bush captures and channels this leakage rather than letting it spray everywhere.

Why the Clearance Matters

Throttle bushings typically have a nominal 0.025 inch diametral clearance – roughly the thickness of a few sheets of paper. Seal gland throttle bushing to shaft clearance should typically be 0.018 inch to 0.020 inch.

Getting this clearance right is critical:

- Too tight: The bush contacts the shaft, generating heat and wear

- Too loose: The restriction becomes ineffective at containing leakage

Clearances must account for thermal growth of the shaft during operation. A bush that fits perfectly at room temperature might rub when the pump heats up.

Throttle Bush vs Throat Bush: The Key Difference

This is where many people get confused, so let’s slow down. Both are bushings in the seal assembly, both create close clearances, and their names sound nearly identical. But they serve fundamentally different purposes.

The Critical Distinction

| Feature | Throttle Bush | Throat Bush |

|---|---|---|

| Location | Outboard (atmospheric side) | Inboard (impeller side) |

| Purpose | Contains leakage FROM seal | Controls flow INTO seal |

| Position | After the seal faces | Before the seal faces |

The throat bushing sits between the impeller and the seal chamber, controlling how process fluid enters the seal environment. The throttle bushing sits at the opposite end, managing what escapes from the seal.

A Simple Way to Remember

Here’s how I keep them straight:

- Throat bush = at the “throat” of the pump, closer to the impeller

- Throttle bush = “throttles” (limits) leakage to atmosphere

Does Your Mechanical Seal Need a Throttle Bush?

When Throttle Bushings Are Commonly Used

Not every mechanical seal includes a throttle bush. You’ll typically find them in these applications:

- Double mechanical seal arrangements – almost always required

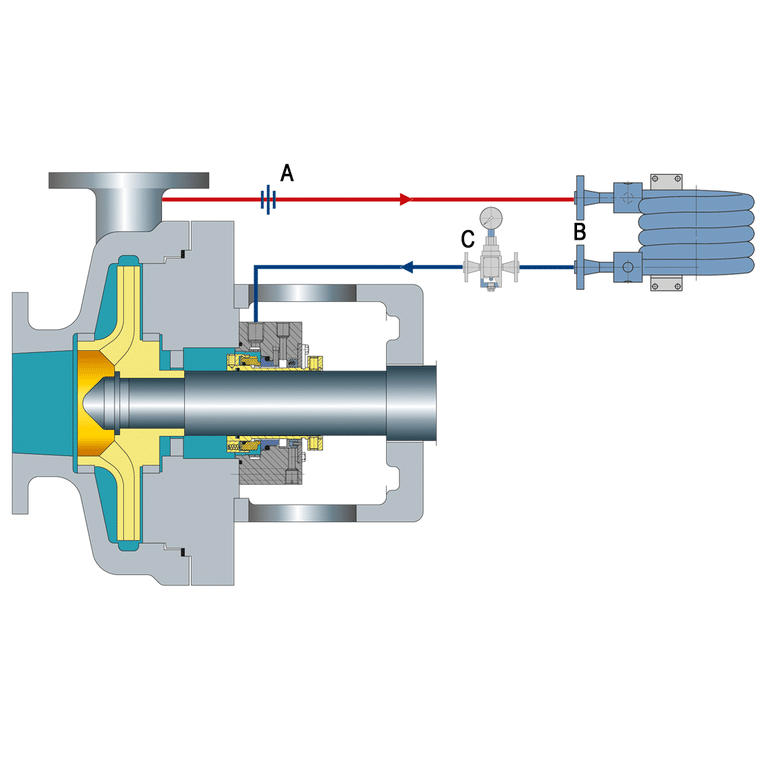

- Applications with flush plans, especially Plan 62 (quench) and Plan 66

- Hazardous fluid applications where any leakage must be contained

- Systems where leakage must be directed to a specific drain point

When You Might Not Have One

Many simpler seal arrangements don’t include throttle bushings:

- Basic single seal setups without flush systems

- Non-critical applications where minor external leakage is acceptable

- Older pump designs predating modern containment requirements

Check Your Documentation

Look at your seal drawing or parts list. If you’re working with API 682 specifications, the standard provides guidance on when bushings are required. For Category 1 applications, fixed throttle bushings are the default. Categories 2 and 3 specify floating bushings that can move slightly with the shaft.

Common Throttle Bush Materials

Material Options

Throttle bushings come in several materials, each suited to different conditions:

- Bronze: Good wear resistance with self-lubricating properties

- Carbon: Handles high temperatures, naturally self-lubricating

- PEEK (polymer): Excellent corrosion resistance, eliminates risk of pump seizure

- Stainless steel: Durable with good chemical resistance

Quick Selection Guidance

For most standard applications, bronze or carbon work well. If you’re dealing with corrosive fluids, consider PEEK or stainless steel options.

When in doubt, match the original specification from your seal manufacturer. Changing materials without understanding the application can create new problems – a harder material might score the shaft, while a softer one might wear too quickly.

Your Next Step

Now you understand what a throttle bush does and why it matters. The key takeaway: always check bushing condition during any seal work. A worn bushing often hides behind repeated seal failures.

Ready to find the right replacement parts for your mechanical seal? Contact our team to discuss your application.