What Is PTFE Mechanical Seal

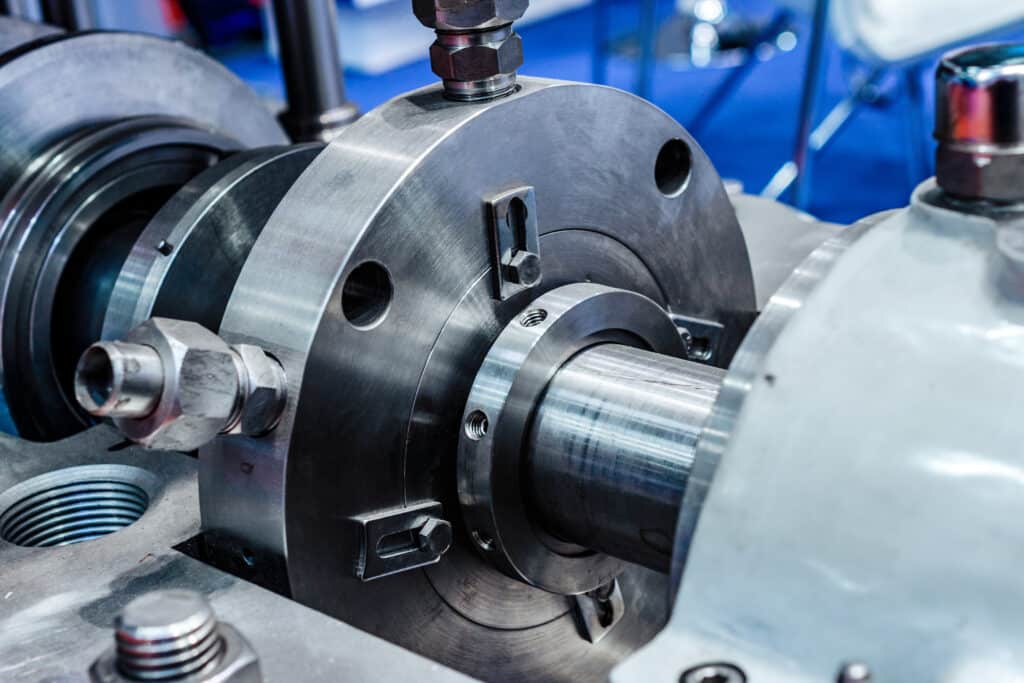

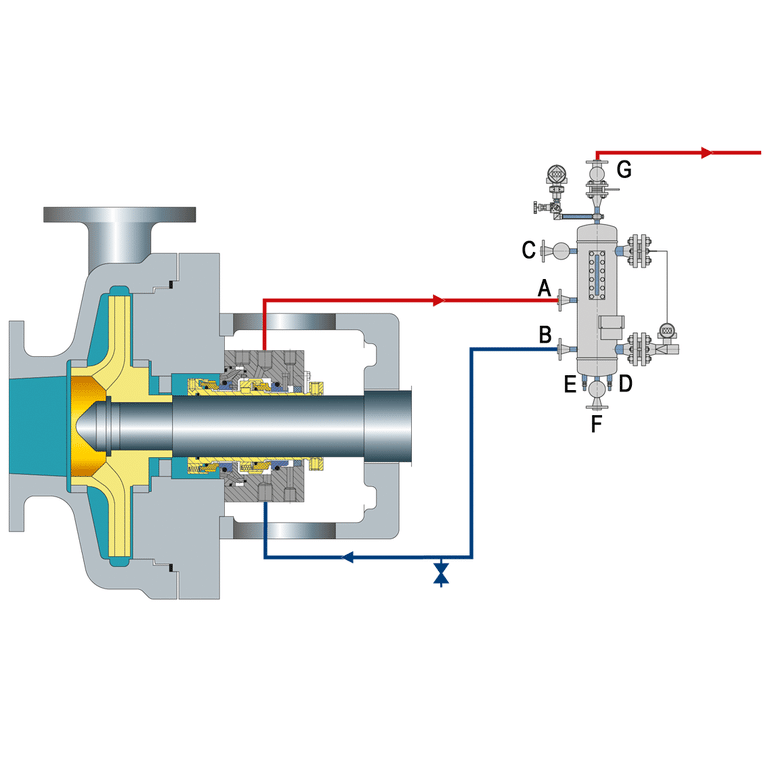

PTFE (polytetrafluoroethylene) mechanical seals are widely used sealing solutions in various industries. These seals consist of a PTFE sealing element that provides a leak-tight barrier between two surfaces, preventing fluid or gas leakage. PTFE, commonly known by the brand name Teflon, is a synthetic fluoropolymer with exceptional chemical resistance, low friction, and high temperature stability.

PTFE mechanical seals typically feature a PTFE sealing element, such as a PTFE wedge or PTFE lip seal, that is energized by a spring or other mechanism to maintain contact with the mating surface. The PTFE material’s unique properties enable the seal to conform to surface imperfections, compensate for misalignment, and minimize wear on the sealing surfaces.

Key Material Properties and Temperature Range

| Property | Value |

|---|---|

| Chemical Resistance | Excellent (pH 0-14) |

| Coefficient of Friction | 0.05-0.2 |

| Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Tensile Strength (at break) | 20-35 MPa (2,900-5,000 psi) |

| Elongation (at break) | 200-400% |

| Hardness (Shore D) | 50-65 |

| Thermal Conductivity | 0.25 W/mK |

| Dielectric Constant | 2.1 (at 1 MHz) |

Advantages of PTFE Mechanical Seal

- Excellent chemical resistance: PTFE is highly resistant to a wide range of chemicals, including acids, bases, solvents, and oils, making PTFE mechanical seals suitable for use in chemically aggressive environments.

- Low friction coefficient: The low friction properties of PTFE help reduce wear and tear on the seal faces, extending the seal’s service life and minimizing the risk of leakage.

- Wide temperature range: PTFE mechanical seals can operate effectively in temperatures ranging from -200°C to +260°C, making them suitable for both cryogenic and high-temperature applications.

- Non-stick properties: PTFE’s non-stick surface prevents the buildup of contaminants on the seal faces, reducing the risk of seal failure and ensuring consistent performance over time.

- Excellent dry running capabilities: PTFE mechanical seals can run dry for short periods without suffering damage, providing an added level of protection against seal failure in case of temporary lubrication loss.

- Low maintenance requirements: The self-lubricating properties of PTFE reduce the need for frequent maintenance and lubrication, resulting in lower overall maintenance costs and increased system uptime.

- Conformability: PTFE’s ability to conform to mating surfaces helps compensate for minor misalignments or surface imperfections, ensuring a tight seal and reducing the risk of leakage.

- FDA compliance: Certain grades of PTFE are FDA-compliant, making them suitable for use in food, beverage, and pharmaceutical processing equipment where hygiene and product purity are critical.

Disadvantages of PTFE Mechanical Seal

- Limited pressure capability: PTFE seals are generally limited to low to moderate pressure applications, typically up to 20 bar (290 psi). Higher pressures may cause excessive deformation or extrusion of the PTFE material.

- Creep and cold flow: PTFE is prone to creep and cold flow under constant load, which can lead to seal leakage over time. This limitation can be mitigated by proper seal design and material selection.

- Poor thermal conductivity: PTFE has low thermal conductivity, which can lead to heat buildup in dynamic sealing applications. This can be addressed by incorporating heat-dissipating features or using filled PTFE compounds with improved thermal properties.

- Limited abrasion resistance: While PTFE has excellent chemical resistance and low friction, it has relatively poor abrasion resistance compared to other sealing materials. Abrasive media can cause accelerated wear of PTFE seals.

What Is The Application of PTFE Mechanical Seal

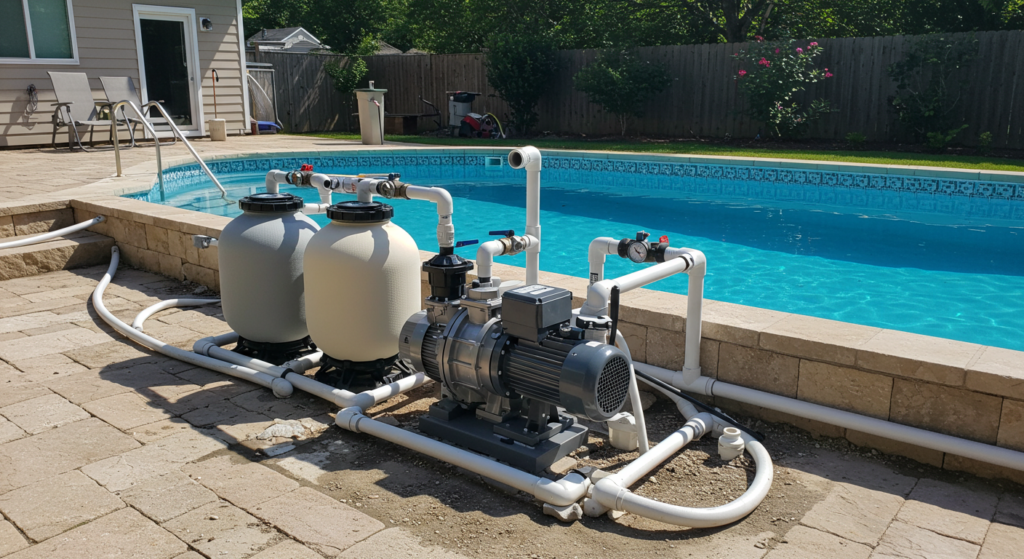

- Chemical processing: PTFE seals are widely used in pumps, valves, and other equipment handling aggressive chemicals, thanks to their excellent chemical resistance.

- Food and pharmaceutical: PTFE’s non-stick properties and FDA compliance make it suitable for sealing applications in food and pharmaceutical processing equipment.

- Aerospace: PTFE seals are used in aircraft hydraulic systems, fuel systems, and other critical applications due to their wide temperature range and chemical resistance.

- Automotive: PTFE seals are found in automotive fuel systems, brake systems, and other fluid handling components, where their low friction and chemical resistance are beneficial.

- Oil and gas: PTFE seals are used in downhole tools, valves, and other equipment exposed to harsh chemicals and high temperatures in the oil and gas industry.

- Cryogenics: PTFE’s low-temperature performance makes it suitable for sealing applications in cryogenic systems, such as liquid nitrogen or helium handling equipment.