What exactly is a split seal?

Our blog post breaks down the basics of split seals, their benefits, and how they can improve your operations.

What is Split Seal

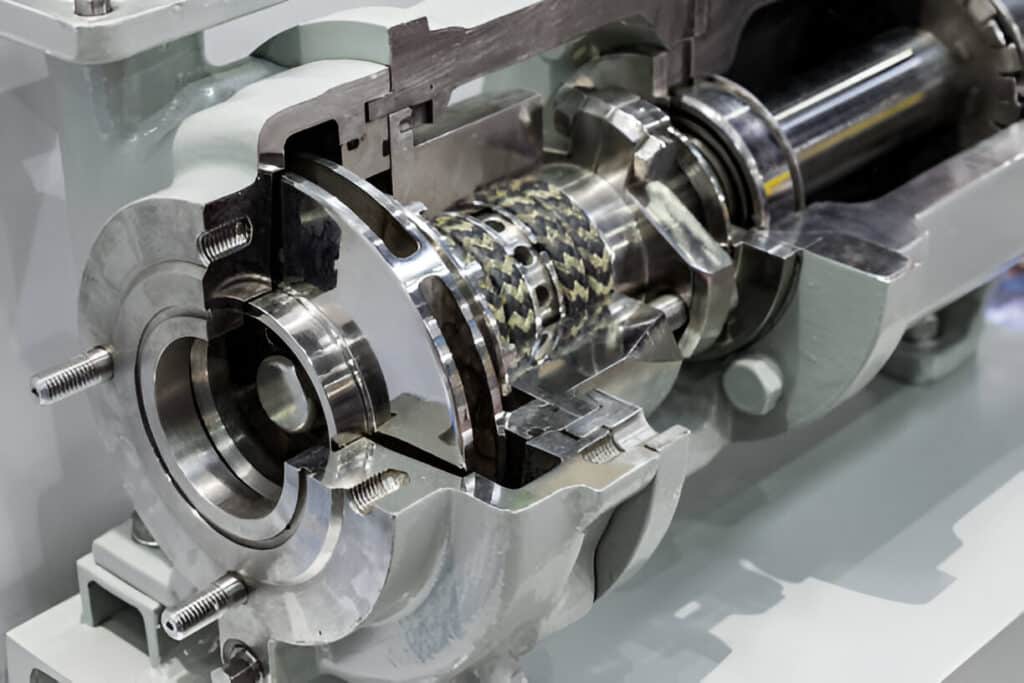

Split seal is a type of mechanical seal that consists of two sealing faces split into multiple segments. This unique design allows for better pressure distribution and improved sealing performance compared to traditional single-piece seals.

The split configuration also enables easier installation and maintenance, as the seal can be assembled around the shaft without requiring complete disassembly of the equipment. Split seals are commonly used in pumps, mixers, and other rotating equipment, particularly in industries such as oil and gas, chemical processing, and water treatment.

Split seals work by creating a fluid barrier between the two halves of the seal, preventing leakage and maintaining pressure within the system.

Benefits of Split Seal

- Ease of Installation: Split seals offer a straightforward installation process, significantly reducing downtime. There is no need to dismantle the equipment, making it a practical choice for maintenance.

- Cost-Effective: By eliminating the need to disassemble machinery, split seals save on labor costs and minimize production losses.

- Enhanced Performance: Split seals provide reliable sealing even in challenging environments. They effectively prevent leaks and contamination, ensuring optimal equipment performance.

- Versatility: Suitable for a wide range of applications, split seals are compatible with various types of equipment and industries, from pumps to mixers.

- Extended Equipment Lifespan: By maintaining a secure seal, split seals help in reducing wear and tear on machinery components, thereby extending the overall lifespan of the equipment.

Limitations of Split Seal

- Installation Complexity: Installing a split seal can be more complex compared to traditional seals, requiring precise alignment to ensure proper functioning.

- Higher Initial Cost: Split seals often come at a higher initial cost due to their specialized design and materials.

- Limited Pressure Range: The pressure-handling capabilities of split seals are generally lower, making them unsuitable for high-pressure applications.

- Maintenance Requirements: Regular maintenance is crucial for split seals to prevent leaks, which can increase operational downtime.

- Potential for Misalignment: Misalignment during installation can lead to seal failure, necessitating careful handling and expertise.

- Size Limitations: Split seals may not be available for all sizes of shafts, limiting their applicability in certain industrial settings.

Applications of Split Seal

- Pumps: Split seals are commonly used in pumps to prevent fluid leakage while allowing for easy maintenance and installation.

- Mixers and Agitators: In industries where mixers and agitators are used, split seals help to ensure a tight seal and prevent contamination.

- Compressors: Split seals are crucial in compressors to maintain pressure integrity and prevent gas leaks.

- Turbines: In turbine applications, split seals contribute to efficient operation by minimizing leakage and maintaining system integrity.

- Marine Propulsion: Split seals are used in marine propulsion systems to ensure watertight seals and protect against harsh marine environments.

- Pulp and Paper Industry: Split seals are employed in the pulp and paper industry to handle the demanding conditions and prevent leakage of chemicals and slurry.

- Chemical Processing: In chemical processing plants, split seals are used to contain hazardous materials and ensure safe operation.

FAQs

What is the difference between a split seal and a cartridge seal?

A split seal comes in two halves that are assembled around the shaft, while a cartridge seal is a pre-assembled unit that is installed as a complete package.

In Conclusion

In conclusion, split seals offer an efficient solution for equipment maintenance. They minimize downtime and reduce costs. Their design ensures easy installation and reliable performance. For industries requiring frequent maintenance, split seals are a valuable investment.