Seal chamber pressure and suction pressure are not the same—seal chamber pressure is typically higher and directly affects your mechanical seal’s performance and lifespan.

While suction pressure measures the fluid pressure at the pump inlet, seal chamber pressure exists in the cavity where your mechanical seal operates, usually elevated by impeller back vanes and recirculation.

What is Seal Chamber Pressure

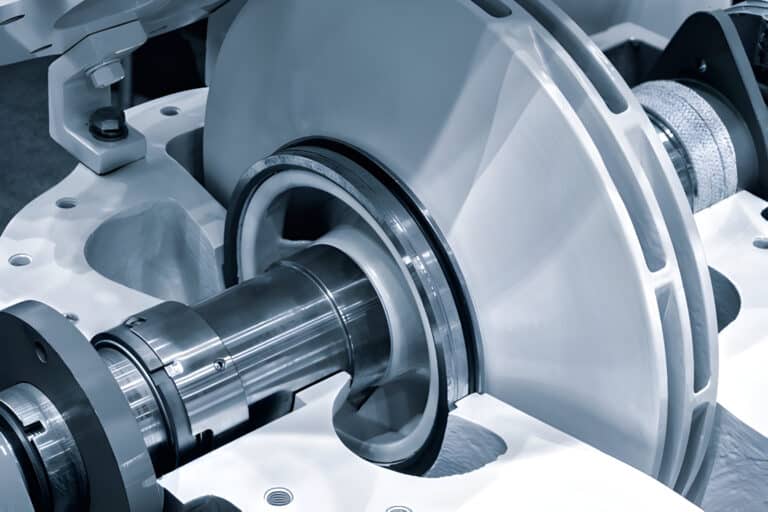

Seal chamber pressure is the actual fluid pressure inside the cavity where your mechanical seal operates. This pressure directly contacts the seal faces and determines how your seal performs.

The seal chamber (also called the stuffing box) sits between the pump impeller and the atmosphere. Here, pressure builds up from several sources: fluid recirculation from the impeller, back vane effects, and any external flush systems you’re using.

Think of it as the working environment for your mechanical seal. Just like a diver experiences different pressure at depth, your seal faces experience this specific pressure during operation.

Typical seal chamber pressure runs 10-15 PSI higher than suction pressure in most centrifugal pumps. However, this can vary significantly based on your pump design and operating conditions.

What is Suction Pressure

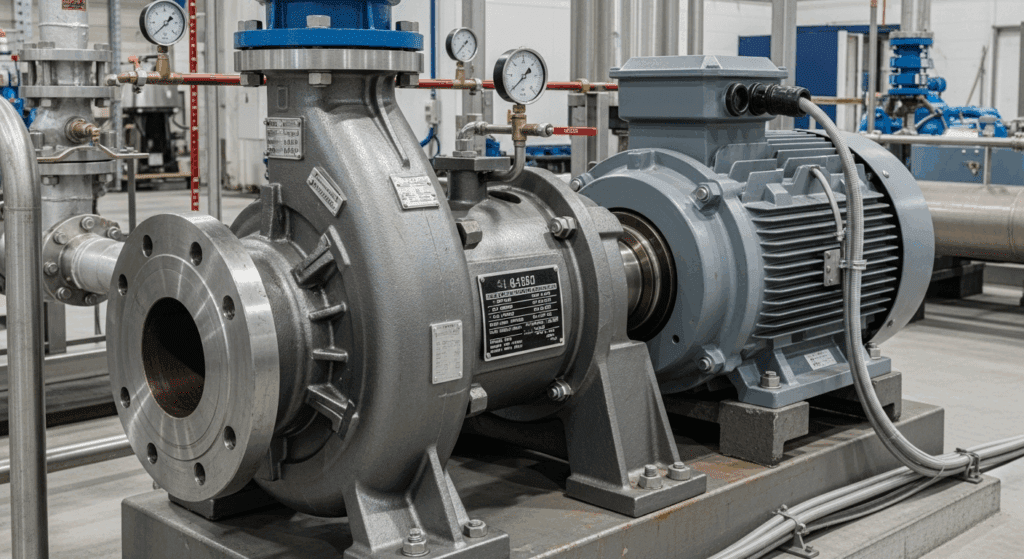

Suction pressure is the fluid pressure at your pump’s inlet flange, before the impeller does any work. It’s your starting point for understanding pump hydraulics.

This pressure comes from your system conditions: tank elevation, system pressure, or booster pump discharge. It’s what pushes fluid into your pump impeller eye.

You measure suction pressure with a gauge at the pump inlet, typically recorded as PSIG (gauge pressure) or PSIA (absolute pressure). This reading tells you what’s available before your pump adds energy.

Is Seal Chamber Pressure the Same as Suction Pressure

No, seal chamber pressure and suction pressure are distinctly different values in your pump system. Confusing them leads to wrong seal selection and unexpected failures.

The key difference: location and magnitude. Suction pressure exists at the pump inlet, while seal chamber pressure develops behind the impeller where your seal operates.

In a typical centrifugal pump, seal chamber pressure exceeds suction pressure. The impeller’s rotation creates this pressure differential through hydraulic action.

Here’s what happens: fluid enters at suction pressure, gains energy through the impeller, and some recirculates into the seal chamber. This recirculation raises the pressure above inlet conditions.

FAQs

How do I measure seal chamber pressure directly?

Install a pressure gauge or transducer directly in the seal chamber through a tapped port. Many pumps have plugged ports for this purpose. Take readings at normal operating conditions for accurate values.

Can seal chamber pressure ever be lower than suction pressure?

Yes, when pumps use back pump-out vanes specifically designed to reduce seal chamber pressure. Some slurry pumps employ this design to minimize solids accumulation and reduce pressure on the seal faces.

Does seal chamber pressure change with flow rate?

Yes, seal chamber pressure varies with pump operating point. Running far from BEP (Best Efficiency Point) typically increases seal chamber pressure due to increased recirculation and hydraulic losses.

What happens if seal chamber pressure is too high?

Excessive seal chamber pressure causes increased face loading, higher heat generation, and accelerated wear. It can also exceed the seal’s pressure rating, causing immediate failure or distortion of seal components.