Single and double cartridge mechanical seal systems differ primarily in their number of sealing interfaces and complexity. Single cartridge seals use one set of seal faces to prevent fluid leakage from pumps and rotating equipment. Double cartridge seals employ two sets of seal faces with a barrier fluid between them, providing enhanced protection and reliability.

The main differences lie in their structure, performance capabilities, and applications. Single seals work well for standard applications with non-hazardous fluids. Double seals excel in demanding environments with dangerous, expensive, or environmentally sensitive fluids.

What Is Single Cartridge Mechanical Seals

Single cartridge mechanical seals are pre-assembled units containing one set of seal faces that prevent fluid leakage along a rotating shaft. These seals come as complete assemblies ready for installation.

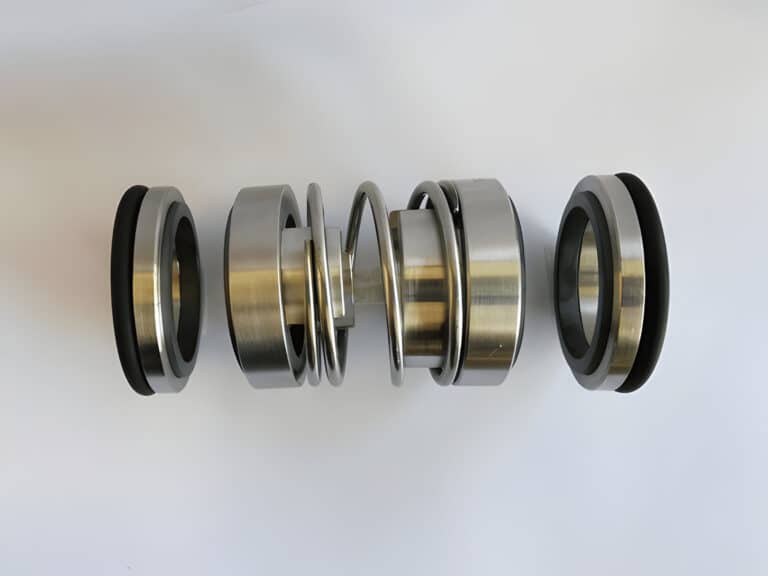

The design includes a stationary face, a rotating face, springs, and secondary sealing elements like O-rings. All components are mounted on a single sleeve or housing.

Installation is straightforward because the seal arrives pre-set with correct spring compression and face loading. You simply slide the entire unit onto the shaft and secure it in place.

These seals work well for most general-purpose applications. They handle clean fluids, moderate pressures, and standard operating temperatures effectively.

The cartridge design eliminates measurement errors during installation. This feature reduces seal failures caused by incorrect assembly.

What Is Double Cartridge Mechanical Seals

Double cartridge mechanical seals feature two complete sets of sealing faces arranged in series. A barrier or buffer fluid circulates between the two seal sets.

This design creates redundant sealing protection. If the primary seal fails, the secondary seal prevents process fluid leakage.

The barrier fluid system serves multiple purposes. It lubricates both seal faces, removes heat, and provides a clean environment for the seals to operate. This fluid can be pressurized above process pressure or unpressurized depending on the application needs.

Double seals protect against hazardous, toxic, or valuable process fluids. They’re standard in pharmaceutical, chemical, and petroleum refining industries where leakage poses serious risks.

The Difference Between Single and Double Cartridge Mechanical Seals

Structure and Components

Single cartridge seals contain one set of sealing faces with supporting components. The assembly includes rotating and stationary faces, springs, and secondary seals in a unified cartridge.

Double cartridge seals have twice the components. Two complete seal sets work together with a barrier fluid chamber between them. This requires additional housing space and more complex internal arrangements.

The structural difference affects overall seal size. Double seals need approximately twice the axial space of single seals.

Sealing Mechanism

Single seals create one sealing point between rotating and stationary faces. Process fluid pressure and spring force maintain face contact.

Double seals operate with two independent sealing mechanisms. The inboard seal faces the process fluid. The outboard seal contains the barrier fluid. Both sets work simultaneously to prevent leakage.

Sealing Faces

Single cartridge designs use one pair of precision-lapped faces. These faces must handle all sealing duties alone.

Double designs employ two pairs of sealing faces. This distributes wear and provides backup protection. Each face pair can be optimized for its specific duty – process side or barrier side.

Fluid Interface

Single seals contact process fluid directly on one side. The other side faces atmosphere or a simple flush arrangement.

Double seals separate process fluid from atmosphere using barrier fluid. The inboard faces see process fluid. The outboard faces see only clean barrier fluid. This isolation protects seal faces from contamination.

Leakage Behavior

Single seals leak directly to atmosphere when they fail. Any face damage or wear immediately shows as external leakage.

Double seals leak barrier fluid first when problems develop. This provides early warning before process fluid escapes.

Pressure Capability

Single seals handle pressure based on their single face set capability. Higher pressures create more challenging conditions for the lone sealing interface.

Double seals manage pressure better through load sharing. Barrier fluid pressure can be adjusted to optimize sealing conditions. This enables reliable operation at higher process pressures.

Typical Uses

Single cartridge seals suit most general industrial applications. Clean water service, mild chemicals, and standard process pumps work well with single seals.

Double cartridge seals serve critical applications. Toxic chemicals, volatile organics, and expensive products require double seal protection. Environmental regulations often mandate double seals for certain fluids.

Longevity

Single seals typically last months to years depending on application severity. Face wear directly impacts seal life since no backup exists.

Double seals often run longer. Barrier fluid keeps faces clean and cool. The redundant design prevents catastrophic failure, extending mean time between repairs.

Auxiliary Systems

Single seals need minimal support systems. Basic flush plans provide cooling and cleaning when required.

Double seals require complete barrier fluid systems. Reservoirs, circulation pumps, heat exchangers, and pressure controls support proper operation.

Maintenance

Single seal maintenance focuses on one seal set. Inspection and replacement procedures remain straightforward.

Double seal maintenance involves more components. Both seal sets need attention. Barrier fluid requires periodic replacement. Support system components need regular service. However, condition monitoring is easier with barrier fluid analysis.

Cost

Single cartridge seals cost less initially. Fewer components and simpler support systems reduce purchase price.

Double cartridge seals represent higher investment. The seal itself costs more. Barrier fluid systems add significant expense. Installation labor increases.