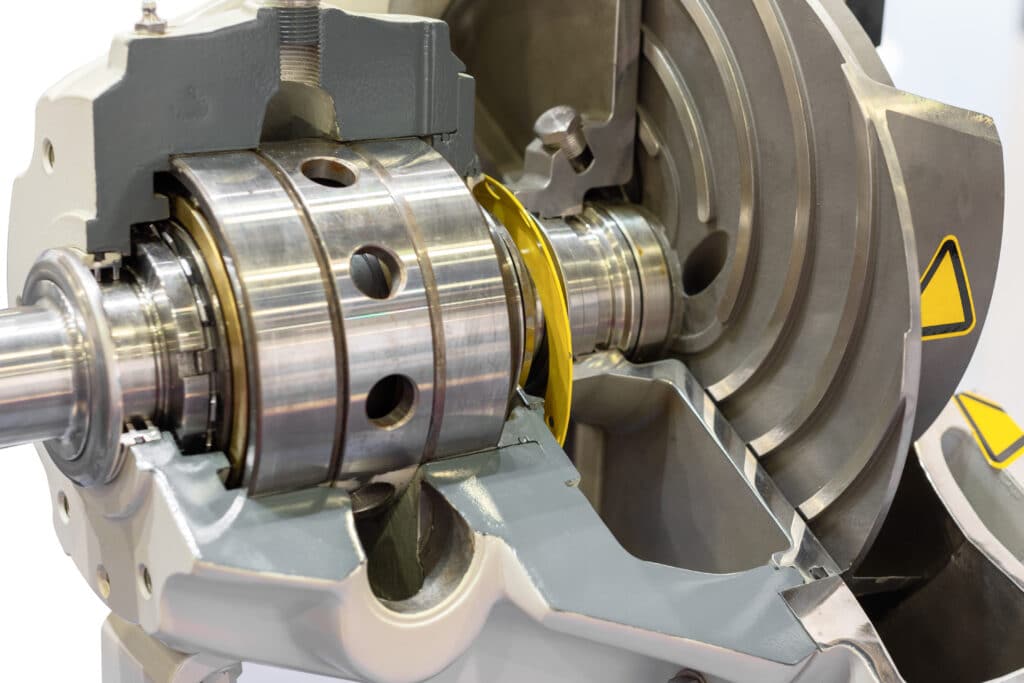

When it comes to mechanical seals, the most widely used type is the pusher seal, also known as a conventional mechanical seal. This seal consists of a rotating primary ring mounted on the shaft and a stationary mating ring housed in the seal gland. The primary ring is typically made of a hard material like silicon carbide, while the mating ring is usually a softer material such as carbon or PTFE.

Pusher seals are popular due to their versatility and reliability in a wide range of applications, from pumps and compressors to mixers and agitators. They can handle moderate to high pressures and temperatures, making them suitable for various industries, including oil and gas, chemical processing, and water treatment.

One of the key advantages of pusher seals is their simple design, which makes them easy to install, maintain, and replace. The seal faces are held together by springs or bellows, ensuring constant contact and minimizing leakage. Additionally, pusher seals can be designed with multiple springs or bellows to provide better pressure resistance and extend seal life.