A pressure tank is a crucial component of a well water system. It works in conjunction with a well pump to provide consistent water pressure throughout a home or building.

This article will delve into the purpose of a pressure tank, how it works, and why running a well pump without it can cause significant issues.

The Vital Role of Pressure Tanks

Pressure tanks serve several key functions within a well water system:

- Storing water under pressure: A pressure tank accumulates water that has been pumped from the well, storing it under pressure. This stored water is readily available for use when a tap is turned on or an appliance calls for water.

- Maintaining consistent water pressure: The pressure tank helps to maintain a stable and consistent water pressure in the plumbing system. It does this by providing water at a predetermined pressure range, minimizing fluctuations and ensuring that water flows evenly when needed.

- Reducing pump cycling frequency: The pressure tank significantly reduces the number of times the well pump turns on and off. By storing water, it allows the pump to run less frequently and for longer durations, as opposed to short bursts of operation.

How a Pressure Tank Works

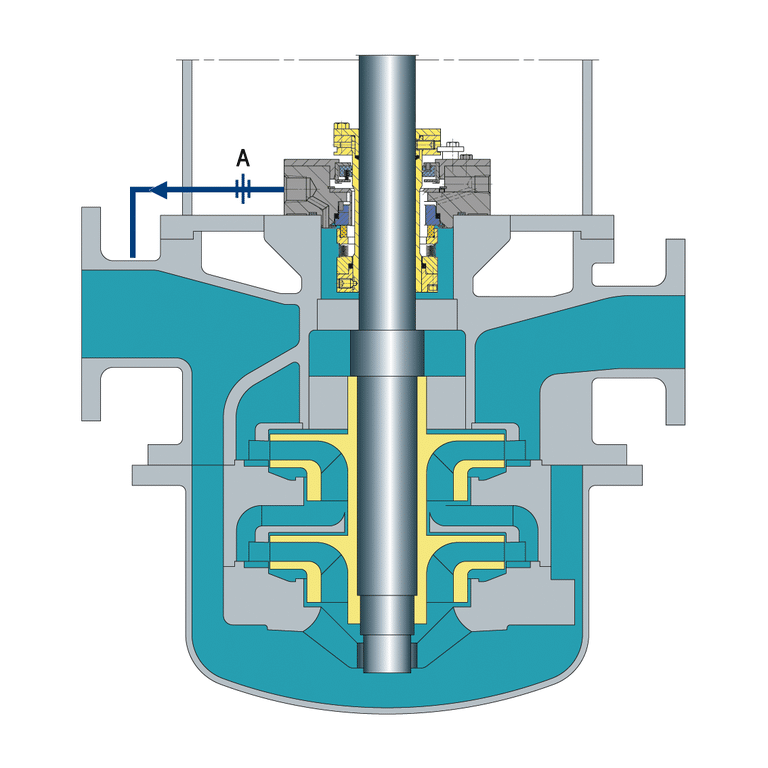

A typical pressure tank has two main sections: a water chamber and an air chamber, separated by a flexible diaphragm or bladder. When the well pump is activated, it fills the water chamber with water, which compresses the air in the air chamber. This compression creates pressure within the tank.

The pressure switch monitors this pressure, and when it reaches a set level, the pump turns off. When water is used, the pressure within the tank decreases as the water is pushed out into the plumbing system. The pressure switch will then activate the pump when the pressure reaches a lower preset level, refilling the tank.

Why You Should NOT Run a Well Pump Without a Pressure Tank

Operating a well pump without a pressure tank is highly discouraged due to the numerous problems and potential damages it can cause to the system. These problems include short cycling, water hammer, inconsistent water pressure, reduced pump lifespan, and system damage.

Short Cycling

- Mechanics: Short cycling refers to the rapid and frequent on-off cycles of the well pump. Without a pressure tank to store water, the pump has to start every time water is needed and then shut off as soon as the pressure reaches the cut-off point, even if the demand for water is still there.

- Impact: These rapid starts and stops put significant stress on the pump’s motor and components. The frequent starts of the motor generates heat, which can lead to premature wear and tear of the pump, and potential motor burnout. The pump’s lifespan can be drastically reduced because it is forced to work much harder.

- Cost: Short cycling leads to higher energy consumption. Each pump start requires a surge of electricity, and frequent starting leads to increased energy usage and higher electricity costs.

Water Hammer

- Define: Water hammer is the pressure surge that occurs when the flow of water in pipes is suddenly stopped, such as when a valve is quickly closed or a pump stops abruptly. When there is no pressure tank in place, there is nothing to absorb this shock.

- Damages: Water hammer can cause loud banging noises in the pipes and can potentially damage pipes, fittings, and appliances. These damages can range from minor leaks to complete pipe bursts.

Inconsistent Water Pressure

- Fluctuating pressure: Without a pressure tank, the water pressure fluctuates significantly. The pressure will be high when the pump is running, but will drop immediately when the pump turns off. This leads to an erratic and inconsistent water flow and pressure, which can cause discomfort and operational issues.

Reduced Pump Lifespan

- Wear and tear from frequent starts/stops: The frequent on and off cycles of the pump, which occur without a pressure tank, cause significant mechanical stress on its internal components. Each time the pump starts, it experiences a surge in power and wear on its parts such as bearings and seals.

- Increased costs: Due to this increased stress, the pump will fail much faster than if it was working with a pressure tank, leading to higher costs associated with repairs or a complete replacement of the pump.

System Damage

- Damage other components: The detrimental effects of short cycling and water hammer aren’t limited to the well pump. These issues can also compromise other components of the well system, such as pressure switches, control valves, and plumbing fixtures. Over time, short cycling and water hammer will lead to costly repairs.