It’s essential to consider how the fluid interacts with seal materials when selecting mechanical seals, as this affects performance and lifespan.

Evaluating factors like viscosity, chemical composition, lubrication regimes, and contamination issues will guide you in making informed decisions that boost system reliability.

Fluid Properties

Viscosity

Viscosity measures a fluid’s resistance to flow and significantly impacts seal performance and longevity. Evaluating fluid compatibility necessitates considering both dynamic and kinematic viscosity.

High-viscosity fluids present challenges for mechanical seals by increasing heat generation due to fluid shear. This can lead to seal face distortion or excessive wear. Proper heat dissipation mechanisms and harder seal face materials can manage these issues. Conversely, low-viscosity fluids might fail to provide adequate lubrication between seal faces, resulting in higher friction and wear rates.

Viscosity also impacts the seal’s ability to maintain a stable fluid film between the seal faces. Adjusting seal face topography or balance ratio may be necessary to optimize performance for specific viscosity ranges.

Purity

Highly pure fluids, such as those used in the pharmaceutical or semiconductor industries, demand specialized seals. These seals must maintain their integrity without contaminating the process. Conversely, fluids with higher impurity levels require robust seals with enhanced filtration or flushing systems to prevent damage.

Assessing the presence of abrasive particles, chemical contaminants, and dissolved solids in the fluid. These impurities can impact the seal face materials, secondary seals, and seal component metallurgy. For instance, abrasive particles can cause excessive wear on seal faces, while certain chemical contaminants may degrade elastomeric components.

Volatility

When handling volatile fluids, their propensity to vaporize under normal operating temperatures and pressures must be carefully evaluated.

Highly volatile fluids are prone to flashing, where liquid transforms into vapor at the seal faces, potentially causing dry running and increased wear.

For less volatile fluids, seal selection may be more flexible. However, localized boiling at the seal faces, induced by frictional heat, should not be overlooked. This can still result in seal instability and reduced lifespan.

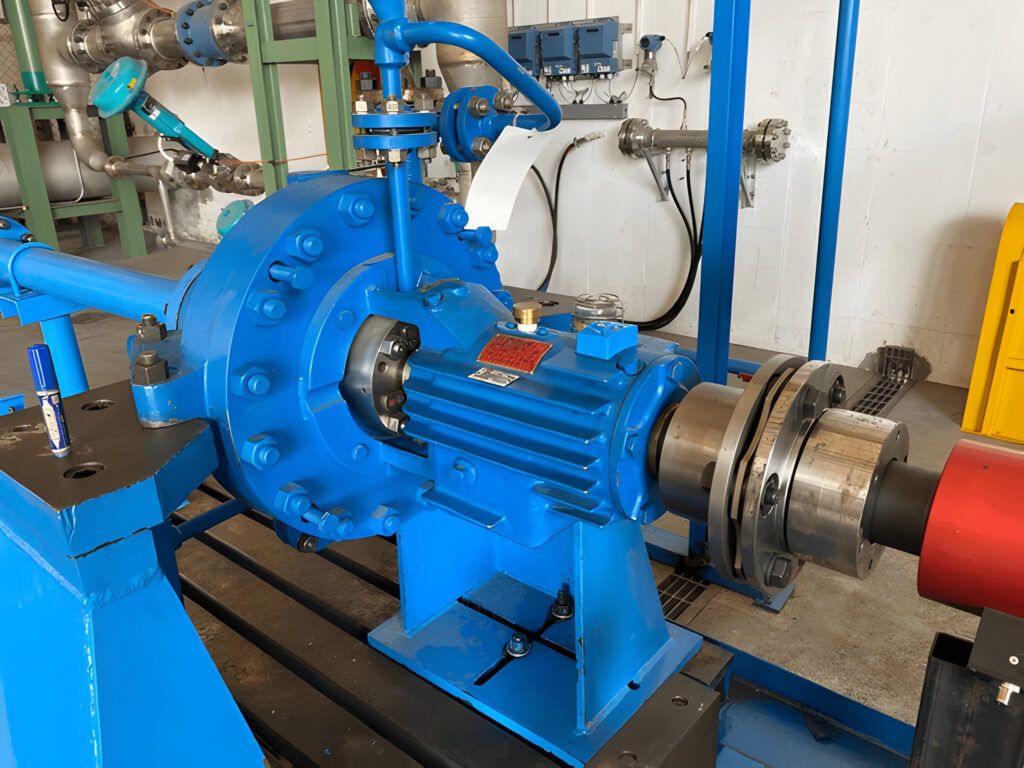

Toxicity

For highly toxic fluids, double mechanical seals or hermetically sealed pumps can minimize leakage risks. Ensure seal materials are chemically resistant to the toxic fluid to prevent degradation and potential breaches.

Lubrication Regime

When selecting a mechanical seal, you’ll need to consider the lubrication regime that will occur between the seal faces. This regime can be classified into three main types: boundary, mixed, and full fluid film.

Boundary

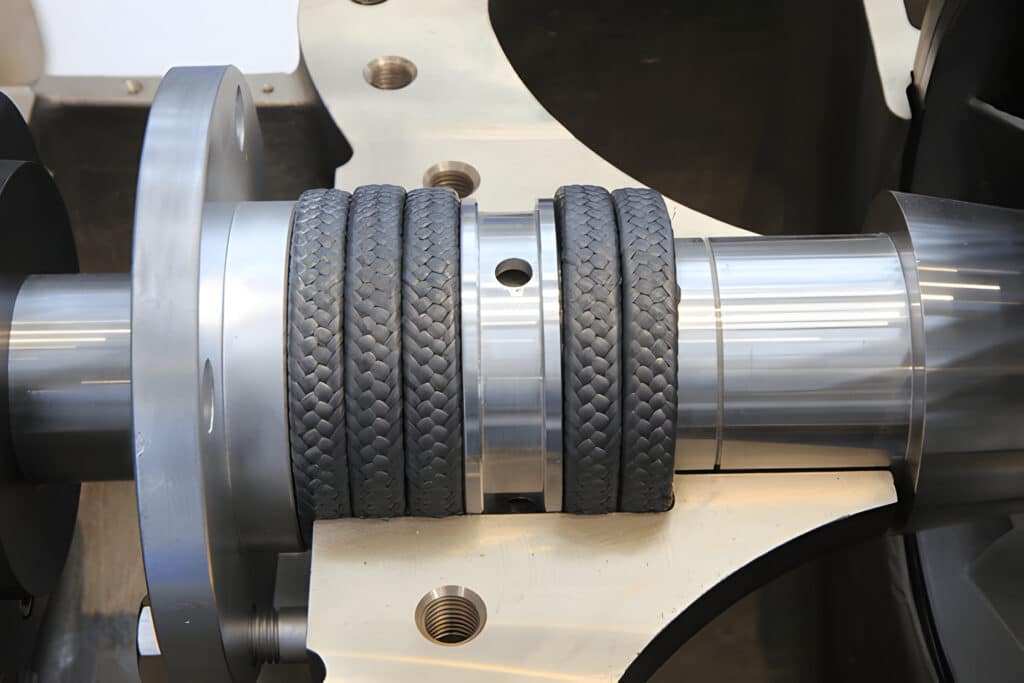

Boundary lubrication in mechanical seals occurs when the fluid film thickness diminishes, causing asperities on opposing surfaces to come into contact. This condition typically surfaces during startup, shutdown, or low-speed operations. Under boundary lubrication, the load is predominantly supported by the surface asperities rather than the fluid film.

In boundary lubrication, reliance on the fluid film for heat dissipation is insufficient. Adequate heat removal must be ensured through additional means, such as flushing or cooling systems. Employing specialized boundary lubricants or additives that form protective films on the seal surfaces can significantly reduce wear and extend seal life.

Mixed

In mixed lubrication, both boundary and hydrodynamic lubrication coexist. This transitional state sees the load partially supported by fluid pressure and partially by asperity contact.

Mixed lubrication typically occurs during start-up, shutdown, or sudden changes in operating conditions. It is marked by intermittent contact between the seal faces, resulting in increased wear compared to full fluid film lubrication.

The proportion of fluid film to boundary lubrication can vary widely in mixed regimes. Design your seal to handle these fluctuations, ensuring smooth transitions between lubrication states without compromising performance or lifespan.

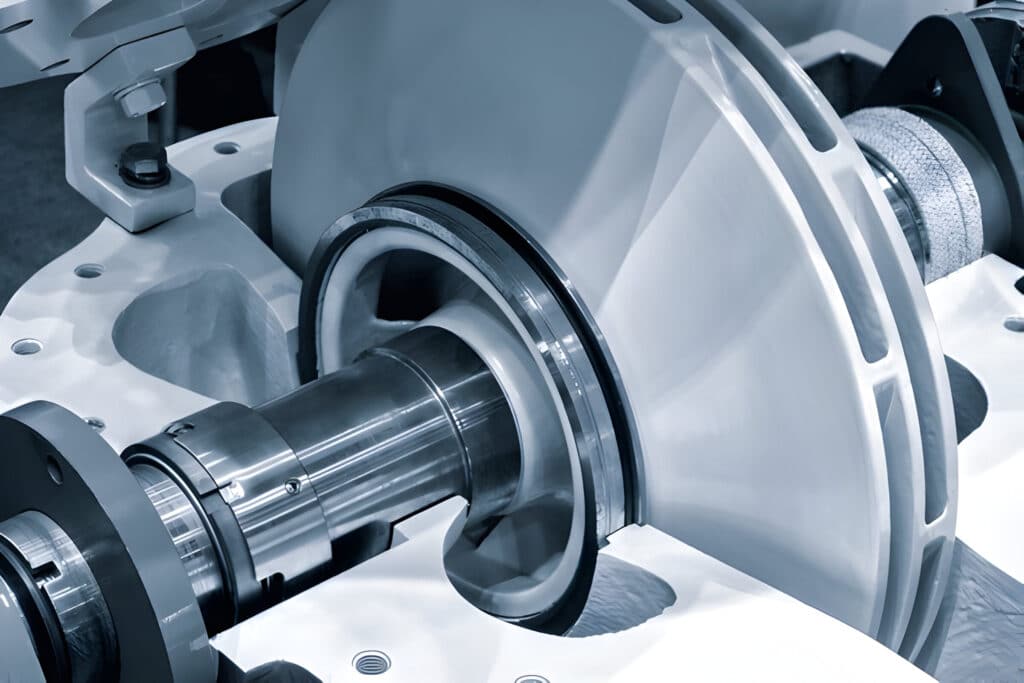

Full fluid film

Full fluid film lubrication represents the highest level of mechanical seal performance, achieved when seal faces are entirely separated by a thin fluid layer. This separation occurs due to the hydrodynamic pressure generated by the fluid being sufficient to counteract the closing force. In this regime, wear is nearly eliminated, and friction is minimized, enhancing the longevity and reliability of the seal.

Contamination

Abrasive particles

Three major concerns arise when dealing with abrasive particles in mechanical seal applications.

First, these particles can cause excessive wear on seal faces, leading to premature seal failure. Second, they can accumulate between seal faces, preventing proper sealing and causing leakage. Third, abrasive particles can damage secondary sealing elements, such as O-rings or gaskets.

Solids

Solid contaminants particles can range from microscopic to visible and may originate from external sources or form within the system itself.

Crystallization

Crystallization occurs when dissolved solids in the fluid precipitate out of solution, forming solid crystals that accumulate on seal faces and other components.

Crystallization can cause increased wear on seal faces, resulting in premature seal failure. Crystals can also build up in small clearances, restricting movement and potentially causing seal hang-up. In extreme cases, crystallization can completely block seal flush ports or other critical passages.

Chemical Compatibility

Reactions between fluid and seal materials

Potential interactions between the process fluid and seal components must be scrutinized, as these can result in degradation, corrosion, or even complete seal failure.

Evaluating the fluid’s chemical composition, temperature, and concentration. For example, fluoroelastomers like Viton® exhibit resistance to many oils and solvents but may degrade when exposed to certain ketones or amines.

Metal components are also susceptible to chemical attacks. While stainless steels are known for their corrosion resistance, they can be vulnerable to specific chemicals or concentrations. Titanium and Hastelloy® alloys provide enhanced resistance for more aggressive fluids.

Effects on binder, filler materials

Binders, typically polymers or resins, provide structural cohesion for the composite, while fillers enhance properties like strength and thermal conductivity.

Certain fluids can adversely affect the binder, causing it to soften, swell, or dissolve. Such interactions lead to seal degradation, compromised structural integrity, and potential seal failure.

Fillers, such as carbon, graphite, or ceramic particles, are also susceptible to fluid interactions. Some fluids may cause fillers to leach out, diminishing the seal’s effectiveness. In other scenarios, fluids might react with the filler, altering its properties or causing expansion.

Seal Face Material Selection Guidelines

Low viscosity fluids

When selecting seal face materials for low viscosity fluids, you’ll need to consider soft vs hard face combinations for boundary and mixed lubrication conditions. You’ll find that soft face materials, like carbon, often pair well with harder counterfaces like silicon carbide or tungsten carbide. This combination can provide better conformability and wear resistance in challenging low-viscosity applications where full fluid film lubrication may not always be maintained.

High viscosity fluids

When selecting seal face materials for high viscosity fluids, you’ll want to prioritize hard vs hard face combinations. This approach helps minimize the high shear forces that can occur between the seal faces. By choosing materials like silicon carbide or tungsten carbide for both faces, you’ll reduce the risk of excessive wear and maintain seal integrity in viscous environments.

Presence of hard abrasive particles

When facing fluids with hard abrasive particles, you’ll need to prioritize seal face materials with higher hardness. You should consider options like tungsten carbide or silicon carbide, which offer superior resistance to abrasive wear.

Fluids prone to crystallization

When dealing with fluids prone to crystallization, you’ll need to consider specialized seal designs. Opt for configurations that keep the process fluid at the outer diameter of the seal, reducing the risk of crystal formation between the faces. You should also select hard vs hard face materials with special features designed to minimize crystal buildup and maintain seal integrity.

FAQs

How Often Should Mechanical Seals Be Inspected for Fluid Compatibility Issues?

Mechanical seals should be inspected for fluid compatibility issues at least quarterly, during routine maintenance, and whenever there are changes in fluid or operating conditions.

Can Fluid Compatibility Change Over Time Due to Temperature Fluctuations?

Yes, fluid compatibility can change over time due to temperature fluctuations. Temperature shifts can alter fluid properties, causing chemical reactions or physical changes that impact the interaction with seal materials.

Are There Specific Fluid Compatibility Tests for Different Seal Types?

Yes, specific tests for different seal types include immersion, volume swell, and hardness change.