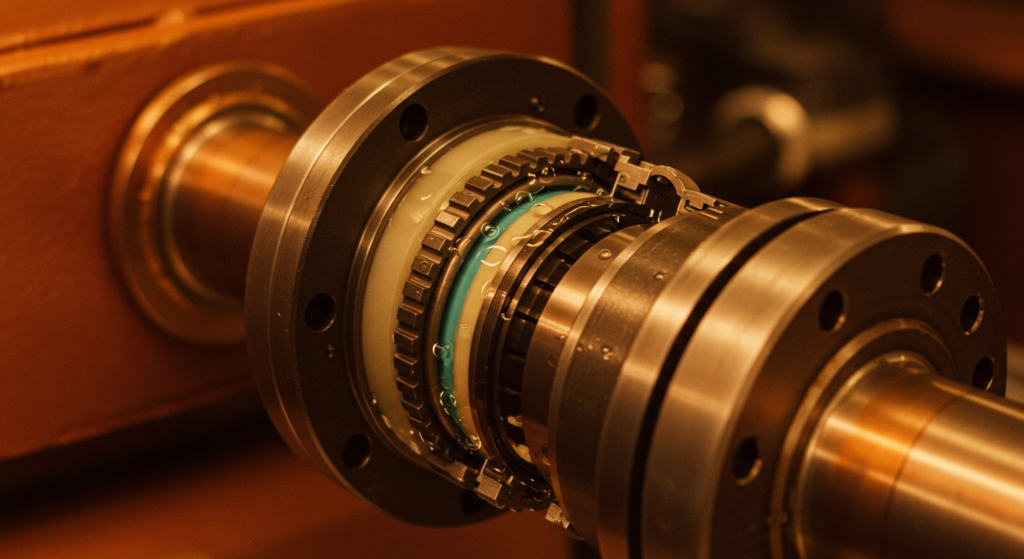

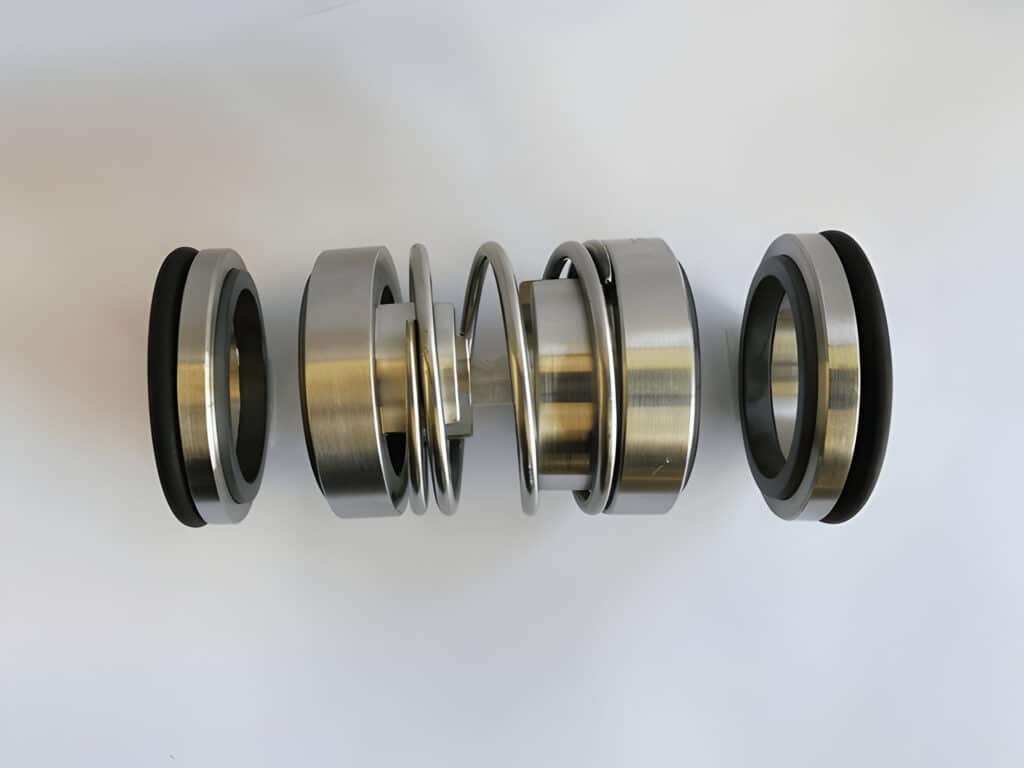

Mechanical seals are critical components in various industrial machines, preventing leakage and ensuring optimal performance. Proper lubrication of these seals is paramount for maintaining their integrity and prolonging their lifespan.

In this blog post, we will delve into the intricacies of lubricating mechanical seals, exploring best practices and key considerations.

Step 1: Select the Appropriate Lubricant

Consult the seal manufacturer’s recommendations or the equipment manual to determine the most suitable lubricant for your specific application. Common lubricants used for mechanical seals include silicone grease, petroleum jelly, and glycerin.

Step 2: Clean the Seal Faces

Before applying the lubricant, thoroughly clean the seal faces to remove any dirt, debris, or old lubricant. Use a clean, lint-free cloth dampened with a suitable solvent, such as isopropyl alcohol, to wipe the seal faces. Ensure that the solvent is compatible with the seal material and evaporates completely, leaving no residue.

Step 3: Apply the Lubricant

Once the seal faces are clean and dry, apply a thin, even layer of the selected lubricant to the seal faces. Use your finger or a small brush to spread the lubricant, making sure to cover the entire sealing surface. Be careful not to apply too much lubricant, as excess can attract dirt and cause contamination.

Step 4: Reassemble the Mechanical Seal

After applying the lubricant, carefully reassemble the mechanical seal, following the manufacturer’s instructions. Make sure that the seal faces are properly aligned and that the seal is seated correctly.

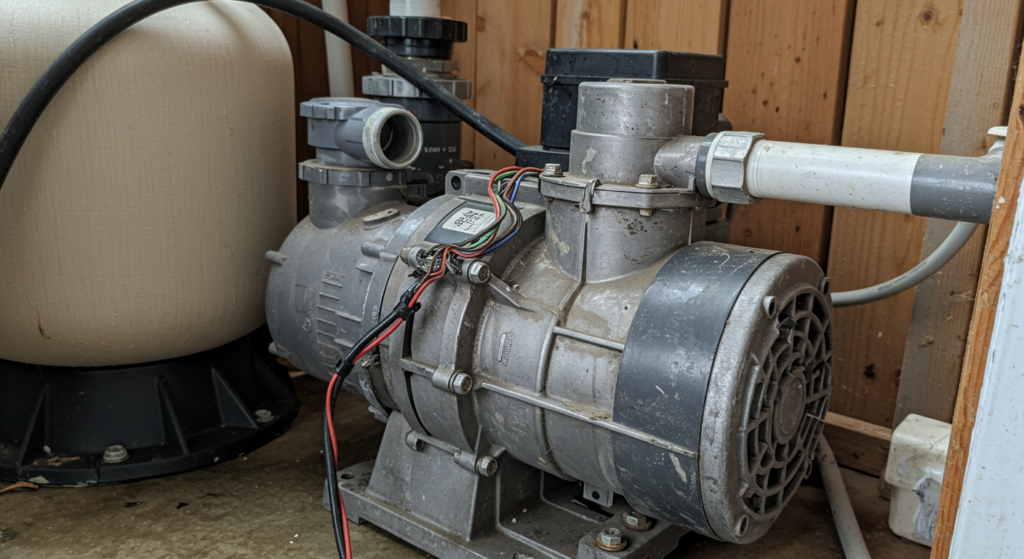

Step 5: Test the Mechanical Seal

Once the mechanical seal is reassembled, test it to ensure proper functionality. Follow the equipment manufacturer’s guidelines for starting up and testing the machinery. Check for any signs of leakage or unusual noises, which may indicate that the seal is not functioning correctly. If issues arise, disassemble the mechanical seal and repeat the lubrication process, ensuring that all steps are followed precisely.