Installing a mechanical seal correctly prevents costly leaks and extends your pump’s life. This guide walks you through each step of the installation process, from gathering tools to final testing.

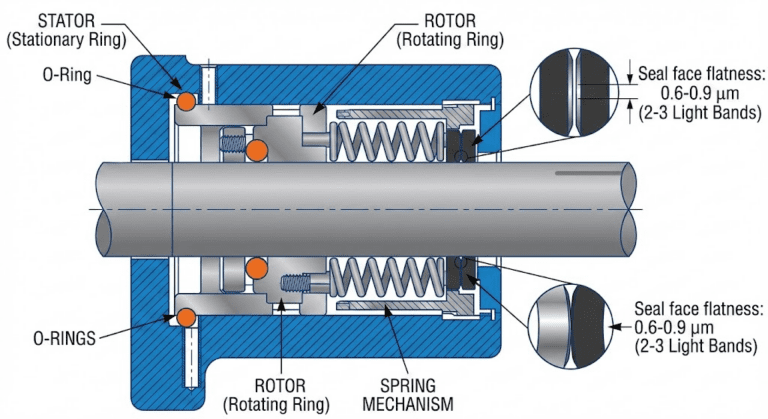

A mechanical seal creates a barrier between rotating and stationary parts using two flat, polished faces pressed together. When you install it properly, only a microscopic film of fluid escapes as vapor—less than half a teaspoon per day.

Tools and Materials Required

- Mechanical seal kit: Get the exact type and size for your pump model, including all sealing faces, O-rings, springs, and gaskets

- Dial indicator: Measures shaft wobble to ensure it stays within 0.05-0.10 mm tolerance

- Calipers or micrometer: Verifies shaft diameter and seal chamber measurements match specifications

- Wrenches and screwdrivers: Allen keys for set screws, socket wrenches for bolts, screwdrivers for gentle prying

- Torque wrench: Prevents over-tightening that warps seals or under-tightening that causes leaks

- Soft-faced mallet: Rubber or plastic head seats components without damaging delicate surfaces

- Cleaning supplies: Lint-free rags and isopropyl alcohol remove all debris from critical surfaces

- Compatible lubricants: Silicone grease for O-rings, water-based lubricant or glycerin for sliding seals onto shafts

- Installation sleeves: Manufacturer-provided tools protect seal faces during assembly if available

- Replacement gaskets: New gaskets for reassembly, even if old ones look intact

Step-by-Step Installation Procedure

Step 1: Shut Down and Isolate the Pump

Lock out the pump’s electrical supply using proper lockout/tagout procedures. This prevents someone from accidentally starting the motor while you’re working.

Close both suction and discharge valves to isolate the pump hydraulically. Remove the drain plug and let all fluid drain completely from the casing.

Step 2: Disassemble the Pump

Remove the bolts connecting the pump frame to the casing. For back pull-out designs, you can leave the casing in place and slide out the rotating assembly.

Disconnect the coupling between the pump shaft and motor shaft. Keep track of all removed parts, bolts, and washers for proper reassembly.

Step 3: Remove the Impeller

Hold the shaft securely while unscrewing the impeller counterclockwise if it’s threaded. For bolt-mounted impellers, remove the central bolt while holding the shaft steady.

Slide the impeller off carefully—you might need a puller if corrosion has seized it. Save any keys, shims, or spacers in their exact order.

Step 4: Extract the Old Seal

Loosen any set screws on the rotating seal collar to free it from the shaft. Gently slide the rotating component off, including the seal face, spring, and collar.

Remove the stationary seal ring from the pump chamber or gland plate. Push it out from behind or carefully pry it loose with a screwdriver, avoiding scratches on the chamber bore.

Step 5: Inspect and Clean All Surfaces

Check the shaft for burrs, scoring, or wear where the seal sits. A worn or grooved shaft needs repair or sleeving before installing the new seal.

Clean the shaft, seal chamber bore, and gland plate thoroughly with lint-free cloth and isopropyl alcohol. Even tiny particles can cause the new seal to leak immediately.

Measure the shaft diameter and chamber bore to confirm they match your new seal’s specifications.

Step 6: Install the Stationary Seal

Apply a thin film of lubricant to the stationary seat’s O-ring. Press the seat straight into the chamber bore with the polished face pointing toward where the rotating face will be.

Use only finger pressure or a specialized tool to seat it evenly. The seat must bottom out in its recess without tilting at an angle.

Step 7: Mount the Rotating Assembly

Lubricate the shaft and the rotating seal’s O-ring lightly with water-based lubricant or glycerin. Slide the rotating component onto the shaft until its face meets the stationary seat.

Position springs according to manufacturer instructions—they often sit between the rotating collar and seal face. Tighten set screws to lock the collar at the specified distance from a reference point on the shaft.

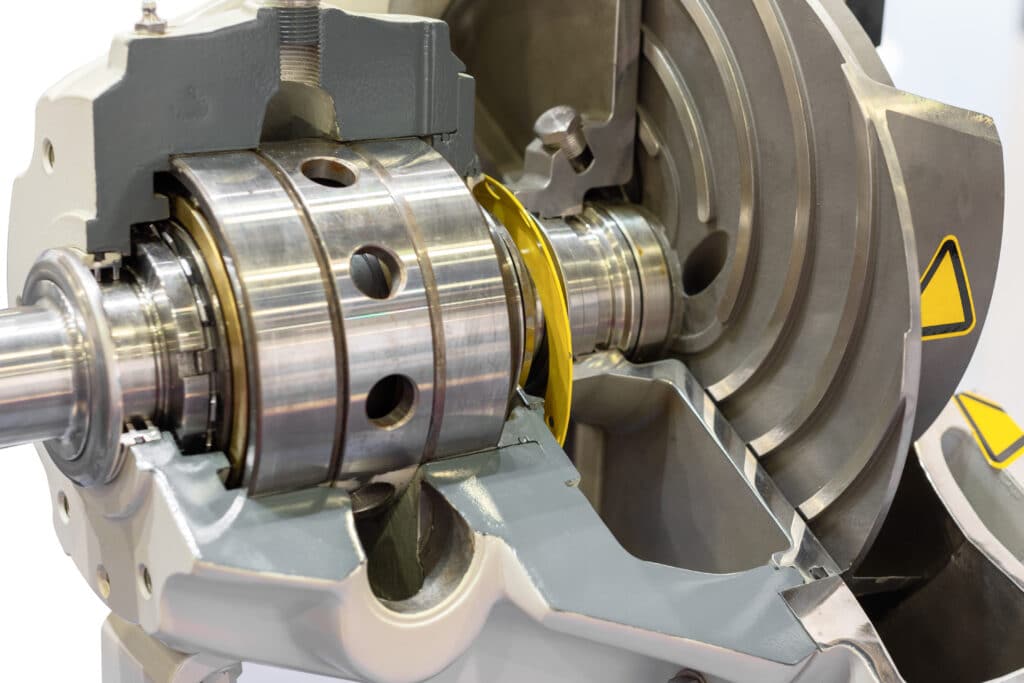

For cartridge seals, slide the entire pre-assembled unit onto the shaft with setting clips in place. Bolt the gland flange to the seal chamber, then remove clips only after everything is secured.

Step 8: Reassemble the Pump

Thread or bolt the impeller back onto the shaft using proper torque specifications. Install new O-rings and gaskets on the impeller hub and seal gland.

Tighten gland bolts gradually in a crisscross pattern to distribute pressure evenly. Use your torque wrench to achieve manufacturer-specified values.

Reconnect the pump casing to the rotating assembly, ensuring the casing O-ring sits properly without pinching.

Step 9: Check Alignment

Align the pump and motor shafts within 0.001-0.002 inches using a dial indicator. Proper alignment prevents vibration that destroys seals prematurely.

Rotate the shaft by hand for 2-3 full turns. It should spin smoothly without binding or scraping sounds.

Step 10: Start and Test

Open the suction valve to fill the pump completely with liquid—never run a mechanical seal dry. Prime any seal flush or cooling systems before starting.

Start the pump at low speed if possible, watching the seal area closely. A properly installed seal shows only vapor-level leakage with no visible dripping after the initial break-in.

Monitor temperature at the seal gland—it should stay relatively cool. Stop immediately if you see continuous dripping or hear unusual noises.

Common Mistakes to Avoid

- Using the wrong seal type: Verify your seal matches the pump’s operating temperature, pressure, and chemical compatibility before installation

- Working with dirty components: Contamination from dust or old gasket material scratches seal faces instantly, causing immediate failure

- Ignoring shaft runout: A bent shaft or worn bearings create wobble that prevents proper sealing—check with a dial indicator before installation

- Setting incorrect seal compression: Over-compressing creates excessive heat while under-compressing leaves faces too loose to seal

- Tightening bolts unevenly: Cranking one bolt fully before others tilts the gland plate and makes seal faces non-parallel

- Installing faces at an angle: Tilted seal faces touch on one side only, breaking the fluid film and causing immediate overheating

- Skipping the rotation test: Always turn the shaft manually before startup to detect binding from misaligned parts or pinched O-rings

- Starting at full speed immediately: Begin with low speed or throttled flow while observing for leaks or overheating signs

FAQs

Can I reuse O-rings from the old seal?

Always use new O-rings and gaskets even if the old ones look intact, as they may have taken a compression set or developed micro-cracks.

How do I know if the shaft needs repair before installing a new seal?

Measure shaft runout with a dial indicator—if wobble exceeds 0.05-0.10 mm or you see visible grooves, the shaft needs straightening or sleeving.