Every pump, mixer, and piece of rotating equipment in your facility relies on one critical component to prevent leaks: the mechanical seal. These precision devices keep fluids where they belong, protecting your equipment, your workers, and your bottom line.

Here’s the problem. Seal-related repairs account for 60-70% of all pump maintenance work. Most of these failures happen because operators and maintenance staff don’t fully understand how the components work together.

I’ve seen countless situations where someone replaced a failed seal with the exact same model, only to watch it fail again weeks later. The root cause? They didn’t understand which part actually failed or why.

What Are the Four Main Components of a Mechanical Seal?

Every mechanical seal, regardless of manufacturer or application, contains four fundamental component groups that work together to create a seal.

What Do Primary Seal Faces Do?

Primary seal faces are the heart of any mechanical seal. These two precision-machined rings press against each other to create the main sealing barrier.

One face attaches to the rotating shaft and spins with it. The other mounts to the stationary housing and stays fixed in place. Where these two faces meet is where the actual sealing happens.

The surfaces are incredibly flat. Manufacturers lap them to a flatness of 0.08 to 0.4 micrometers. To put that in perspective, that’s about 1/1000th the thickness of a human hair. If these faces ran against each other without that lubricating film, they’d generate so much friction and heat that they’d fail within seconds.

What Is the Role of Secondary Seals?

Secondary seals prevent fluid from bypassing the primary seal faces. Think of them as backup seals that close all the gaps between components.

The most common secondary seal is the O-ring. You’ll find O-rings sealing the space between the rotating face and the shaft sleeve, between the stationary face and the gland, and at various other connection points throughout the assembly.

Secondary seals come in two types: static and dynamic. Static seals sit between parts that don’t move relative to each other. Dynamic seals must accommodate movement. The O-ring behind the rotating face, for example, needs to slide along the shaft as the seal faces wear down over time.

Without properly functioning secondary seals, your process fluid would simply leak around the primary faces. You could have perfect primary seal faces and still end up with a leaking pump.

How Do Springs and Loading Mechanisms Work?

Springs push the seal faces together and keep them in contact regardless of operating conditions. Without this constant pressure, the faces would separate and leak.

The spring force serves two critical functions. First, it maintains face contact when the pump isn’t running and there’s no hydraulic pressure to push the faces together. Second, it keeps the faces tracking properly during operation when the shaft might wobble or vibrate slightly.

Different seal designs use different spring configurations. Some use a single large coil spring. Others use multiple smaller springs arranged in a circle. High-temperature applications might use metal bellows that act as both the spring and the secondary seal.

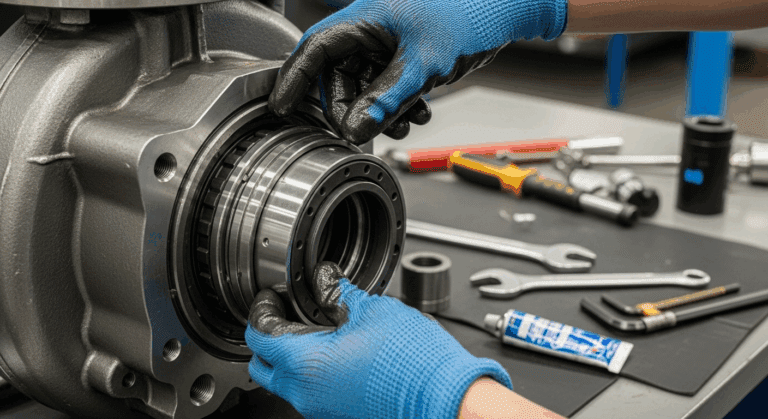

What Hardware Holds Everything Together?

The metal parts and hardware provide structure and mounting for all the sealing components. The gland plate is the most visible piece. It bolts to the pump housing and positions the stationary seal face.

The sleeve slides over the shaft and carries the rotating seal components. Drive mechanisms like set screws or pins transfer rotation from the shaft to the rotating face. Without these, the rotating face would just sit there while the shaft spun inside it.

Setting clips and centering devices serve a specific purpose during installation. They hold the seal assembly in the correct position until you’ve tightened everything down.

What Materials Are Seal Faces Made From?

Face material selection can make or break your seal’s performance. The wrong material pairing leads to rapid wear, excessive leakage, or outright failure.

| Material | Hardness (Mohs) | Max Operating Temp | Best Applications |

|---|---|---|---|

| Carbon Graphite | 1-2 | 350°C (660°F) | Clean fluids, dry running tolerance |

| Silicon Carbide | 9-9.5 | 500°C+ (930°F+) | Abrasive media, high wear environments |

| Tungsten Carbide | 8.5-9 | 400°C (750°F) | High pressure applications |

| Ceramic (Alumina) | 7-9 | 450°C (840°F) | Chemical resistance, cost-effective |

Carbon graphite is the workhorse material you’ll find in most standard applications. It’s self-lubricating, which means it can survive brief dry-running events that would destroy harder materials. The graphite releases microscopic particles that create a lubricating film even when the normal fluid film breaks down.

Silicon carbide offers extreme hardness and wear resistance. I recommend it for any application involving abrasive particles in the fluid. Pumping slurries, sand-laden water, or fluids with suspended solids? Silicon carbide is your friend. It comes in two main types: reaction-bonded for general use and direct-sintered for aggressive chemical applications.

Most seals pair a softer carbon face against a harder ceramic or carbide face. This combination provides good wear characteristics while keeping costs reasonable. Running two hard faces against each other works for specific applications like high-viscosity fluids or when you absolutely need maximum wear resistance.

What Are the Common Elastomer Materials?

Choosing the right O-ring material depends on your process fluid and operating temperature. Using the wrong elastomer is one of the fastest ways to kill a seal.

| Elastomer | Temperature Range | Best For | Avoid |

|---|---|---|---|

| EPDM | -50°C to 150°C (-58°F to 300°F) | Water, steam, alkaline chemicals | Oils, petroleum products |

| Viton (FKM) | -20°C to 210°C (-4°F to 410°F) | Oils, fuels, most chemicals | Steam, hot water, ketones |

| Nitrile (NBR) | -40°C to 120°C (-40°F to 250°F) | Petroleum oils, fuels | Ozone, strong acids, ketones |

| PTFE | -200°C to 260°C (-330°F to 500°F) | Aggressive chemicals, extreme temps | Limited flexibility |

EPDM handles water and steam better than any other common elastomer. If you’re sealing a water pump, boiler feed pump, or anything involving steam, EPDM is probably your best choice. Just keep it away from petroleum products. Oils and fuels cause EPDM to swell and fail.

Viton costs more but handles the broadest range of chemicals. It’s my go-to recommendation for oil refineries and chemical plants where you might encounter multiple different fluids. The higher temperature rating also gives you a safety margin in hot applications.

When Are Bellows Used Instead of O-Rings?

Bellows replace the dynamic O-ring in applications where O-ring hang-up or fretting is a concern. A bellows is a flexible, accordion-like component that can compress and extend while maintaining a seal.

In a “pusher” seal design, the O-ring must slide along the shaft as the seal faces wear. If the fluid deposits solite on the shaft or if corrosion roughens the surface, that O-ring can get stuck. When the faces can’t track properly, you get excessive leakage or catastrophic failure.

Bellows seals are “non-pusher” designs. The bellows flexes to accommodate face wear instead of sliding along the shaft. This makes them ideal for fluids that crystallize, polymerize, or leave deposits.

Metal bellows handle extreme temperatures where elastomers would fail. They’re common in hot oil service, steam applications, and cryogenic systems. Elastomeric bellows cost less and work well in moderate-temperature applications where O-ring hang-up is the main concern.

Conclusion

Mechanical seals contain four main component groups: primary seal faces that create the sealing interface, secondary seals that close bypass paths, springs that maintain face contact, and hardware that mounts everything in place. Each component must function correctly for the seal to work.