Mechanical seal springs are the force-generating components that hold the two sealing faces together in a mechanical seal, preventing leaks in pumps, compressors, and rotating equipment. Without these springs, the seal faces would drift apart, allowing pressurized fluid to escape.

Springs sit at the heart of nearly every rotating equipment system. They’re found in centrifugal pumps for water distribution, chemical processing equipment, food production machines, and HVAC systems. When equipment operates at high speeds or extreme pressures, the spring must maintain consistent force across varying conditions.

The type of spring you choose determines whether your seal lasts months or years. Different spring designs handle different challenges: single springs work well for simple low-pressure applications, while multiple springs manage the demanding high-speed, high-temperature scenarios found in modern industrial equipment.

Single Spring Seals

Single spring seals use one coil spring to generate all the sealing force. The spring sits behind the stationary sealing face, pushing it against the rotating face to create a tight barrier against leakage.

Multiple Spring Seals

Multiple spring seals employ two or more small coil springs arranged in a circular pattern around the seal ring. This design distributes sealing force more evenly than a single spring can achieve.

Wave Spring Seals

Wave spring seals replace traditional coil springs with a specially shaped wavy or sinusoidal spring that provides nearly constant force over a wide range of deflection. This wavy profile looks similar to a rippled metal disc when viewed from the side.

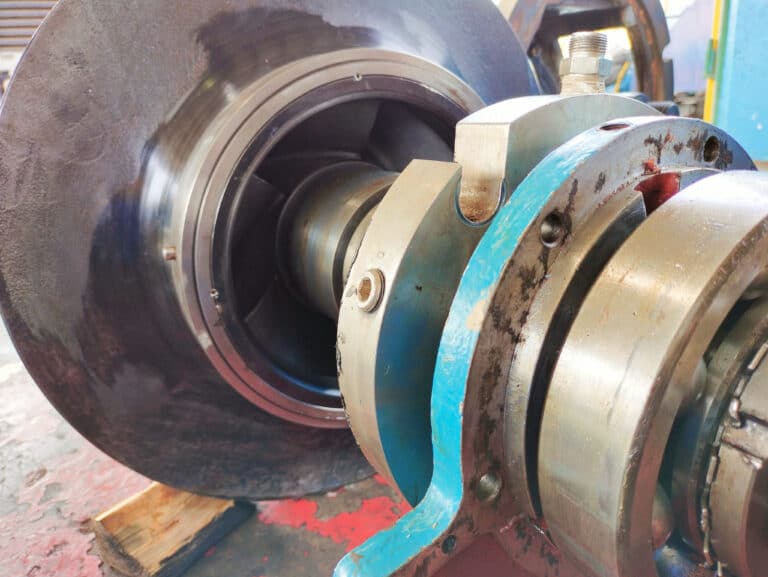

Metal Bellows Seals

Metal bellows seals replace springs entirely with a thin, flexible metal bellows welded directly to the stationary sealing face. The bellows itself generates the sealing force through elastic deformation rather than a mechanical spring.

Conical Spring Seals

Conical spring seals use a specially shaped spring that resembles a shallow cone or funnel. As the spring compresses, it generates progressively increasing force—the more you compress it, the harder it pushes back.

Spring Materials: Selecting for Your Environment

The material your spring is made from determines whether it survives your operating environment or fails prematurely from corrosion, oxidation, or stress.

| Material | Temperature Range | Corrosion Resistance | Cost | Best Applications |

|---|---|---|---|---|

| Stainless Steel 316 | -50°F to +400°F | Good (most fluids) | $ | General industrial, clean fluids |

| Stainless Steel 321 | -50°F to +500°F | Good (oxidizing acids) | $ | Chemical processing, moderate corrosion |

| Inconel 718 | -50°F to +1,000°F | Excellent (high-temperature) | $$$ | Aerospace, high-temperature reactors |

| Hastelloy C-276 | -50°F to +900°F | Outstanding (aggressive acids) | $$$ | Chemical plants, offshore, highly corrosive media |

| Elgiloy | -50°F to +600°F | Good (general service) | $$ | High-temperature standards, precision applications |

How to Select the Right Mechanical Seal Spring

Choosing the correct seal spring requires understanding your operating conditions, fluid properties, and equipment constraints.

Key Selection Criteria

Assess your operating pressure: Systems under 200 PSIG work well with single spring or conical spring seals. Equipment between 200-500 PSIG benefits from multiple spring or wave spring designs. Above 500 PSIG, specify conical springs or metal bellows for reliable performance.

Determine your temperature requirements: Standard elastomers in spring seals work from roughly negative 50 degrees to 400 degrees Fahrenheit. Hotter applications need metal bellows. Colder applications (below negative 40 degrees) require special elastomers or cryogenic metal bellows.

Evaluate fluid characteristics: Clean water and light oils work with any spring type. Abrasive slurries demand tighter clearances and often need ceramic sealing faces paired with multiple springs. Aggressive chemicals like sulfuric acid require metal bellows—they destroy elastomer seals in days.

Measure shaft speed and stability: Speeds below 3,600 RPM allow single spring designs. Speeds between 3,600 and 10,000 RPM need multiple springs. Speeds above 10,000 RPM require wave springs or metal bellows to avoid distortion at high speeds.

Calculate your budget and installation constraints: Single spring seals cost the least but may underperform demanding applications. Multiple spring seals cost 20-40 percent more but last significantly longer in high-speed service. Metal bellows cost 2-3 times more than spring seals but handle extreme conditions where spring seals would fail immediately.

Comparison Guide for Common Applications

Centrifugal pumps (water, light oils, clean fluids): Multiple spring seals at 3,600-7,200 RPM provide the best value and reliability.

High-speed equipment (compressors, spindles, dental drills): Wave springs or metal bellows handle speeds exceeding 10,000 RPM without distortion.

Chemical processing (sulfuric acid, chlorine, caustics): Metal bellows with Hastelloy springs tolerate aggressive fluids that destroy conventional seals.

Cryogenic systems (liquid nitrogen, helium transfer): Metal bellows only—traditional elastomeric seals become brittle at temperatures below negative 100 degrees Fahrenheit.

FAQs

What is the main purpose of a mechanical seal spring?

The spring holds the stationary sealing face against the rotating face with consistent force, creating an effective barrier against leakage even as seal faces wear over time.

Can I replace a single spring seal with a multiple spring seal?

Yes, if the seal sizes and mounting configurations match. Multiple spring seals offer better performance in high-speed or high-pressure applications but require compatible gland designs.

How long should a mechanical seal spring last?

Spring lifespan depends on operating conditions: single spring seals typically last 1-3 years in standard applications, multiple spring seals last 3-5 years in high-speed service, and metal bellows often exceed 5 years in extreme conditions. Corrosion shortens lifespan significantly.