Split mechanical seals are two-piece mechanical seals designed to install around a rotating shaft without disassembling the pump. You wrap them around the shaft, bolt the halves together, and you’re done. No pulling the motor. No removing bearings. No crane lifts.

That simple design change cuts seal replacement time from days to hours.

They’re not right for every application. Split seals have more potential leak paths, so they don’t work for hazardous fluids. And they cost more upfront than conventional seals. But when your equipment is hard to disassemble and downtime is expensive, split seals solve a real problem.

What Is a Split Mechanical Seal and How Does It Differ from Conventional Seals?

What Makes a Seal “Split”?

A split mechanical seal is literally a seal cut in half. Every component—the seal faces, the mating rings, the O-rings, the hardware—comes in two pieces that assemble around your shaft.

The magic is in how manufacturers split these parts. They machine each set as matched pairs, using proprietary cutting methods that ensure the halves fit back together precisely. When you bolt the two sides together on-site, you get a complete seal without ever sliding anything over the shaft end.

This matters because standard seals require you to remove whatever is blocking access to the shaft—motor, coupling, bearings, you name it. Split seals don’t.

How Do Split Seals Compare to Cartridge and Component Seals?

| Feature | Split Seal | Cartridge Seal | Component Seal |

|---|---|---|---|

| Installation | No pump disassembly | Pump disassembly required | Full disassembly required |

| Time to install | 1-2 hours | Several hours | Multiple hours to days |

| Initial cost | Higher | Medium | Lower |

| Leak paths | More | Fewer | Fewer |

| Best for | Large pumps, vertical pumps | General applications | Simple applications |

The key tradeoff is simple: split seals cost more upfront but save a fortune in labor. If you’re sealing a small pump that takes 30 minutes to disassemble anyway, the extra cost doesn’t make sense. But when your equipment weighs tons and requires crane lifts? That’s where split seals shine.

Where Are Split Mechanical Seals Used?

Which Industries Benefit Most?

Split seals make the biggest impact where downtime hurts the most and equipment is hardest to service:

- Water and wastewater treatment plants run large pumps around the clock. When a seal fails at 2 AM, split seals get you back online before the morning shift.

- Pulp and paper mills deal with aggressive slurries that chew through seals. Faster replacements mean less production loss.

- Power generation facilities use split seals on boiler feed pumps, condensate pumps, and cooling water pumps—critical equipment that can’t sit idle.

- Mining operations often have equipment in remote locations where crane access is difficult or impossible.

- Chemical processing plants face the highest downtime costs. When you’re processing thousands of dollars of product per hour, a two-day shutdown versus a two-hour repair makes all the difference.

What Equipment Types Are Best Suited?

Split seals work best on equipment that’s physically difficult to service:

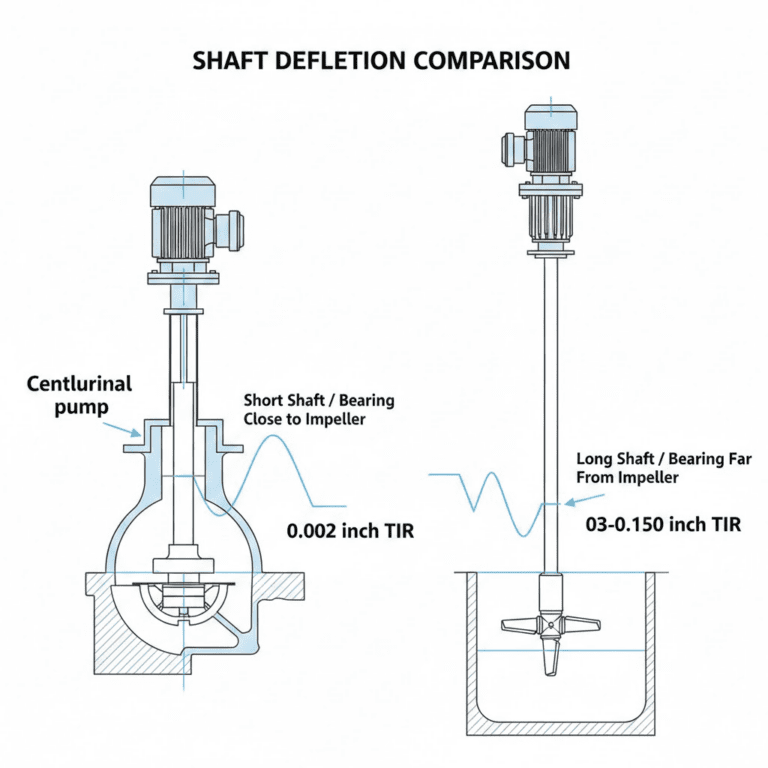

Large vertical pumps are the classic application. Without a split seal, you need a crane to lift the motor just to access the seal. With a split seal, you slide it in place from the side.

Split-case pumps, mixers, and agitators also benefit. Any equipment where pulling the rotating assembly requires significant labor is a candidate.

The ROI math generally works for shaft sizes above 2.5 inches on single-stage centrifugal pumps. Below that, the time savings don’t always justify the price premium. But on specialty equipment or difficult-to-disassemble machinery, even smaller shafts can make sense.

What Are the Limitations of Split Mechanical Seals?

When Should You NOT Use Split Seals?

Split seals aren’t right for every application. I’ll be straight with you about when to choose something else:

- Hazardous fluid applications are the biggest concern. Split seals have more potential leak paths than one-piece designs. If you’re sealing anything toxic, flammable, or regulated for emissions, those extra leak paths create unacceptable risk.

- Zero-leakage requirements rule out split seals. The nature of assembling two halves means you can’t achieve the same seal integrity as a factory-assembled cartridge.

- High-pressure and high-speed applications can push the limits of the split design. At extreme conditions, the centrifugal forces on the rotating components can stress the split joints.

- Specialty material requirements may not be available. Split seals have a narrower material selection than standard designs.

What Material Restrictions Apply?

Materials are where split seals show their most significant limitations.

Elastomers typically come in three options: FKM (fluoroelastomer), EPDM, and FEPM. That covers many applications, but if you need specialty compounds for extreme temperatures or aggressive chemicals, you may be out of luck.

Face materials are generally limited to carbon graphite variants and silicon carbide. You won’t find tungsten carbide split seals—the material’s density and hardness make it impractical to split and reassemble reliably.

If your process demands specific metallurgy or exotic materials, check with manufacturers early. The selection is improving, but it’s still narrower than what’s available in cartridge designs.

Conclusion

Split mechanical seals solve a specific problem: getting seal maintenance done faster on equipment that’s slow to disassemble.

When you need to replace a seal without removing motors, pulling bearings, or calling in cranes, split seals deliver. Maintenance time drops from days to hours.

But they’re not universal. If you’re handling hazardous fluids, need zero leakage, or work with materials outside the available options, standard cartridge seals remain the better choice.