Here’s the truth about mechanical seals: they all leak. But that’s not a problem—it’s by design.

If you’re a maintenance technician or engineer managing industrial pumps and rotating equipment, you’ve probably noticed liquid seeping from your equipment seals and wondered if something’s wrong. The answer is almost always no. A properly functioning mechanical seal needs to leak a small, controlled amount to survive.

Why All Mechanical Seals Leak (And Why That’s Normal)

Mechanical seals must leak to operate properly. They’re controlled leakage devices, not zero-leakage devices.

Here’s why: The seal faces—the rotating ring and stationary ring—maintain a thin liquid film between them. Without this film, the faces would be in direct contact, creating massive friction and heat. The seal would fail within minutes.

That thin film serves three critical functions. First, it lubricates the seal faces, reducing friction between the surfaces. Second, it cools the seal by carrying heat away from the contact point. Third, it maintains pressure between the seal faces, allowing them to create a hydraulic seal.

The only way this film can exist is if a tiny amount of liquid flows across the seal faces. When the seal operates correctly, this leakage migrates away from the primary sealing interface toward areas of lower pressure, where it eventually drips or evaporates.

Think of it like this: a seal that doesn’t leak at all is a seal that’s about to fail catastrophically.

Acceptable Leakage Rate Standards

Now let’s talk numbers. How much leakage is actually acceptable?

The answer depends on your equipment and industry, but here are the baseline standards that engineers rely on:

General Industrial Equipment Benchmarks:

For most industrial applications, a properly functioning mechanical seal will have a leakage rate of 10 drops per hour or less per seal. In more measurable terms, that’s roughly 0.1 to 5 milliliters per hour (ml/hr), depending on the seal type and application.

One drop per minute converts to approximately 2.5 to 3 ml per hour. A milliliter contains about 20 drops, so if you see roughly one drop every few minutes, you’re probably within acceptable limits.

API 682 Standard:

The American Petroleum Institute (API) Standard 682 is the most widely used benchmark in the oil, gas, and chemical industries. API 682 permits a maximum average liquid leakage rate of 5.6 grams per hour (g/h).

For testing purposes, the API 682 Integrity Test measures leakage by pressurizing a 28-liter (1 cubic foot) reservoir to 1.7 bar gauge (25 psig) and measuring pressure drop over 5 minutes. The seal passes if the pressure drop doesn’t exceed 0.14 bar (2 psi).

ISO 21049 Standard:

ISO 21049 addresses mechanical seals for centrifugal and rotary pumps globally. Like API 682, it recognizes that acceptable leakage varies by application. The standard emphasizes that single seals naturally have higher leakage rates than dual seals because they rely on a single barrier to contain fluid.

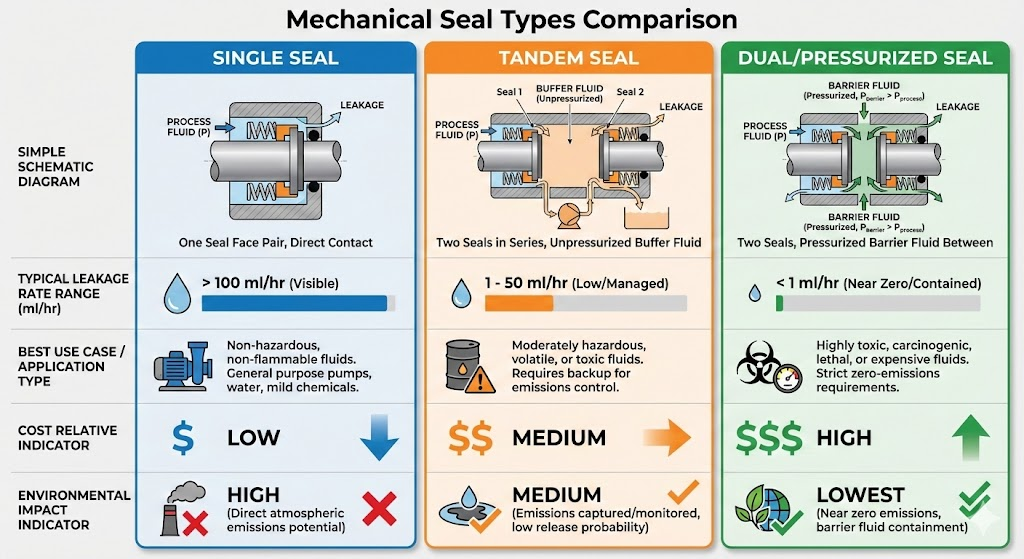

| Seal Type | Typical Leakage Rate |

|---|---|

| Single Seal | 10-50 ml/hr |

| Tandem Seal | 1,000-2,000 ml/day (41.7-83.3 ml/hr) |

| Dual/Pressurized Seal | <1-10 ml/hr |

Leakage Rates by Seal Type

The acceptable leakage rate depends significantly on what type of seal you’re running.

Single Mechanical Seals:

A single seal has one set of seal faces—one rotating ring attached to the shaft and one stationary ring fixed to the equipment housing. Single seals typically have the highest allowable leakage rates among mechanical seal types. These seals generally operate at leakage rates of 10-50 ml/hr for industrial applications.

Single seals are cost-effective and work well for many applications, but they offer less protection against environmental contamination and product loss.

Tandem Mechanical Seals:

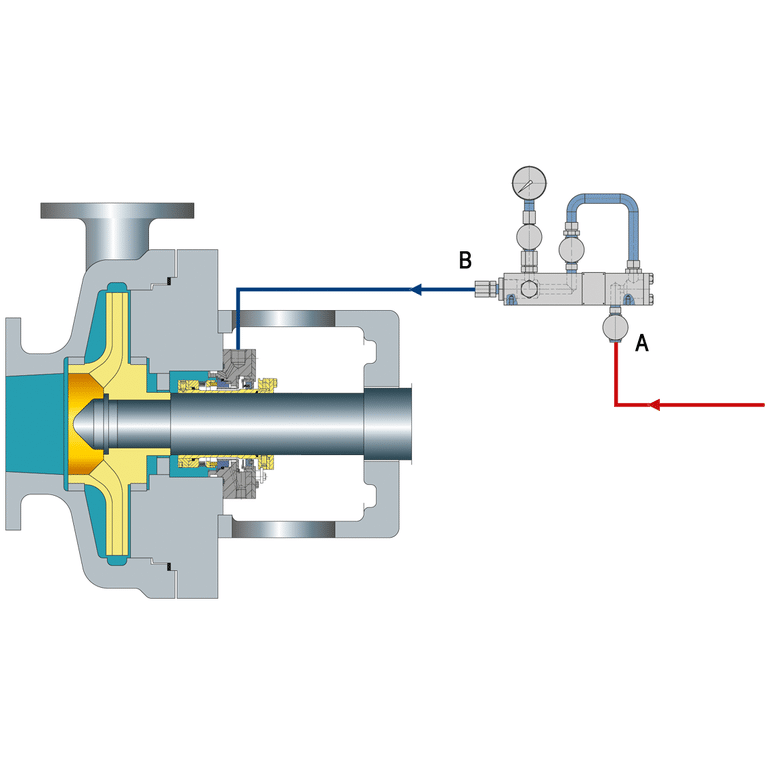

Tandem seals stack two mechanical seals in succession along the shaft. The seal closer to the product (primary seal) handles the sealed fluid, while the secondary seal on the atmospheric side runs on clean buffer fluid.

Tandem seals allow higher system pressures and are often used in critical applications where some leakage can be tolerated but complete sealing isn’t required. API 682 Category II seals using tandem arrangements permit leakage rates up to 1,000 ml per day (roughly 41.7 ml/hr).

Dual/Double Mechanical Seals:

Dual seals have two seal faces with a pressurized barrier fluid circulating between them. The barrier fluid pressure always stays higher than the product pressure, ensuring both seals remain fully pressurized and lubricated.

Dual seals virtually eliminate leakage of the actual product and are the standard in hazardous, toxic, or valuable fluid applications. When properly maintained, dual seals can achieve leakage rates below 1 ml/hr, with some high-performance versions achieving near-zero emissions. API 682 Category III seals permit leakage rates up to 2,000 ml per day (roughly 83.3 ml/hr).

Application-Specific Leakage Standards

Different industries have different leakage requirements based on product value, safety concerns, and environmental regulations.

Food and Beverage Industry:

The food and beverage sector demands extremely tight leakage control. Any cross-contamination between the product and external lubricants creates food safety violations.

Food-grade mechanical seals must comply with FDA regulations and 3-A Sanitary Standards. Acceptable leakage rates in food and beverage applications are typically below 1 ml/hr. Some applications require true zero-leakage designs using dual seals with food-approved barrier fluids.

Seals in food applications must use FDA-approved materials including stainless steel, silicone, EPDM, PTFE, and carbon. The seal design emphasizes smooth, non-porous surfaces that prevent bacterial buildup and allow for self-draining to avoid product residue retention.

Pharmaceutical and Chemical Processing:

The pharmaceutical industry operates under similar strict requirements as food and beverage, with FDA compliance mandatory. Chemical processing requires compatibility between seal materials and the specific chemicals being handled.

In pharmaceutical applications, mechanical seals must prevent any external contamination of sterile products. Many pharmaceutical facilities use pressurized dual seals to achieve compliance with zero-emission requirements.

Oil and Gas Industry:

The oil and gas sector uses API 682 as the standard reference. Different categories of seals apply based on operating pressure and hazard classification:

- Category 1 seals for gauge pressures up to 300 psi

- Category 2 seals for pressures up to 600 psi

- Category 3 seals for special applications up to 600 psi

Offshore and deep-well applications often demand higher reliability and lower leakage rates due to the environmental sensitivity and cost of spills.

Environmental and Zero-Emissions Compliance:

Environmental regulations have become stricter worldwide. The EPA regulates volatile organic compound (VOC) emissions from pumps with vapor pressure above 1.5 psia, establishing strict baseline requirements for U.S. operators.

Germany’s TA-Luft environmental standard has expanded to cover more than 50,000 industrial installations. As local emissions regulations tightened to as low as 50 parts per million (ppm), the seal industry developed dual and advanced gas-lubricated seals to meet near-zero emission standards.

Many facilities now specify dual mechanical seals with pressurized barrier fluids or advanced dry gas-lubricated seals to achieve compliance. These technologies enable operators to operate without continuous emission monitoring, a major cost advantage.

Conclusion

Here’s what you need to remember: all mechanical seals leak, and that’s normal. Your job is to ensure leakage stays within acceptable limits for your equipment and industry.

For most industrial equipment, 10 drops per hour is your baseline acceptable limit. API 682 and ISO 21049 provide specific standards for petroleum, chemical, and food industries. Dual seals dramatically reduce leakage for critical applications where zero emissions or complete product containment matters.