In the machinery industry, effectively sealing rotating shafts is paramount for equipment reliability and performance. Two commonly used sealing solutions are shaft seals and stuffing boxes, each with distinct characteristics and applications.

While both serve to prevent leakage and protect against contamination, shaft seals and stuffing boxes differ in their sealing mechanisms, maintenance requirements, leakage rates, suitable applications, durability, and cost.

What Is Shaft Seal

A shaft seal is a mechanical device designed to prevent leakage of fluids or gases along a rotating shaft. It forms a seal between the shaft and the housing or casing of a machine, such as a pump, compressor, or turbine. Shaft seals are typically installed at the point where the shaft enters or exits the housing.

The primary function of a shaft seal is to contain the process fluid within the equipment while allowing the shaft to rotate freely. It minimizes leakage, reduces contamination, and prevents the ingress of external contaminants into the system.

Shaft seals come in various types, including mechanical seals, lip seals, and labyrinth seals, each with its own unique design and sealing mechanism.

What Is Stuffing Box

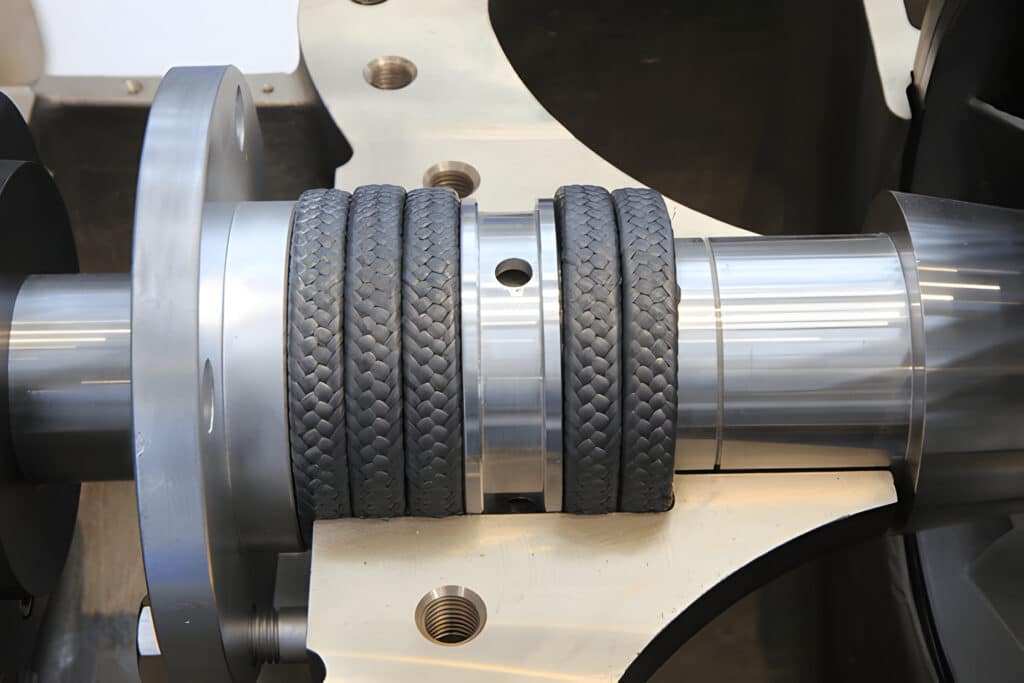

A stuffing box is a type of seal used to prevent leakage around a moving shaft or rod. It is commonly found in pumps, valves, and other mechanical equipment. The stuffing box consists of a cylindrical cavity surrounding the shaft, which is packed with a compressible material called packing.

The packing material is typically made from a soft, pliable material, such as graphite, PTFE, or braided fibers. It is inserted into the stuffing box and compressed around the shaft using an adjustable gland or follower. The compression of the packing creates a tight seal between the shaft and the housing, preventing fluid or gas from escaping.

Key Differences Between Shaft Seal and Stuffing Box

Sealing Mechanism

Shaft seals and stuffing boxes differ in their sealing mechanisms. Shaft seals typically use a mechanical seal, which consists of two flat surfaces pressed together by springs. One surface rotates with the shaft, while the other remains stationary. The seal faces are made of hard, wear-resistant materials like silicon carbide or tungsten carbide.

In contrast, stuffing boxes use packing material, such as braided fibers or graphite rings, compressed around the shaft to create a seal. The packing is held in place by a gland follower and adjusted using gland nuts.

Maintenance

Stuffing boxes require more frequent maintenance compared to shaft seals. The packing material in stuffing boxes needs regular adjustment to maintain proper compression and prevent leakage. Over time, the packing wears out and must be replaced.

Shaft seals, on the other hand, have a longer service life and require less maintenance. However, when a shaft seal fails, the entire unit must be replaced, which can be more time-consuming than replacing packing.

Leakage

Shaft seals provide a more effective seal and exhibit less leakage compared to stuffing boxes. The mechanical seal faces in shaft seals maintain a tight, constant contact, minimizing leakage.

Stuffing boxes, even when properly adjusted, allow a small amount of controlled leakage. This leakage is necessary to lubricate and cool the packing material. However, excessive leakage can occur if the packing is not adequately compressed or if it wears out.

Applications

The choice between a shaft seal and a stuffing box depends on the application. Shaft seals are commonly used in high-pressure, high-temperature, and high-speed applications, such as pumps, compressors, and turbines. They are also preferred in applications where product purity is critical, as they minimize contamination.

Stuffing boxes are often used in lower-pressure and lower-speed applications, such as valve stems, reciprocating pumps, and mixers. They are also suitable for applications where some leakage is acceptable or even desirable for lubrication.

Durability

Shaft seals generally have a longer service life compared to stuffing boxes. The hard, wear-resistant materials used in mechanical seals can withstand harsh conditions and maintain their sealing effectiveness for extended periods.

Stuffing boxes, on the other hand, rely on the packing material, which is subject to wear and degradation over time. The packing needs to be replaced periodically to ensure proper sealing.

Cost

The initial cost of a shaft seal is typically higher than that of a stuffing box. Shaft seals are precision-engineered components that require tight tolerances and high-quality materials, contributing to their higher price point.

Stuffing boxes are simpler in design and use less expensive materials, making them a more economical choice upfront. However, the long-term costs should also be considered. The more frequent maintenance and replacement requirements of stuffing boxes can result in higher operational costs over time.