Mechanical seals prevent fluid leakage along pump shafts, and choosing between component and cartridge types can significantly impact your equipment’s reliability and maintenance costs. Component seals arrive as individual parts that require field assembly, while cartridge seals come as preassembled units ready for installation.

What is Component Mechanical Seal

A component mechanical seal consists of separate parts delivered as a kit containing seal faces, O-rings, springs, and hardware that technicians assemble directly on the pump shaft. These seals require careful piece-by-piece installation where the technician positions the rotating face on the shaft and the stationary face in the seal chamber.

Component seals function as “build-it-yourself” units on the pump. Each element must be mounted individually with precise spring compression settings to achieve proper seal face loading.

The modular design allows you to select different materials and configurations for specific applications. Standard pumps, especially smaller OEM-supplied units, commonly use component seals as their default sealing solution due to lower initial cost and design simplicity.

What is Cartridge Mechanical Seal

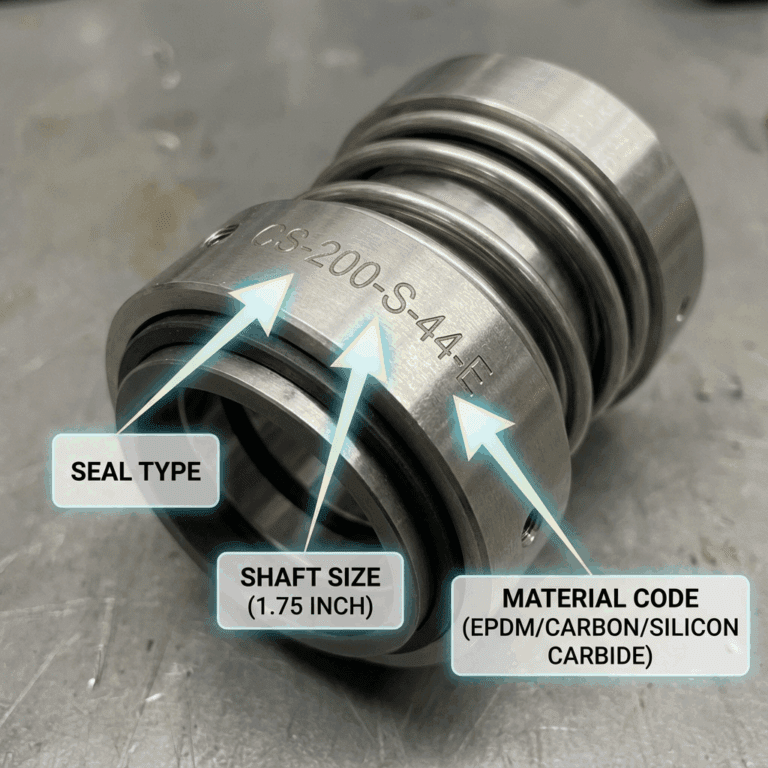

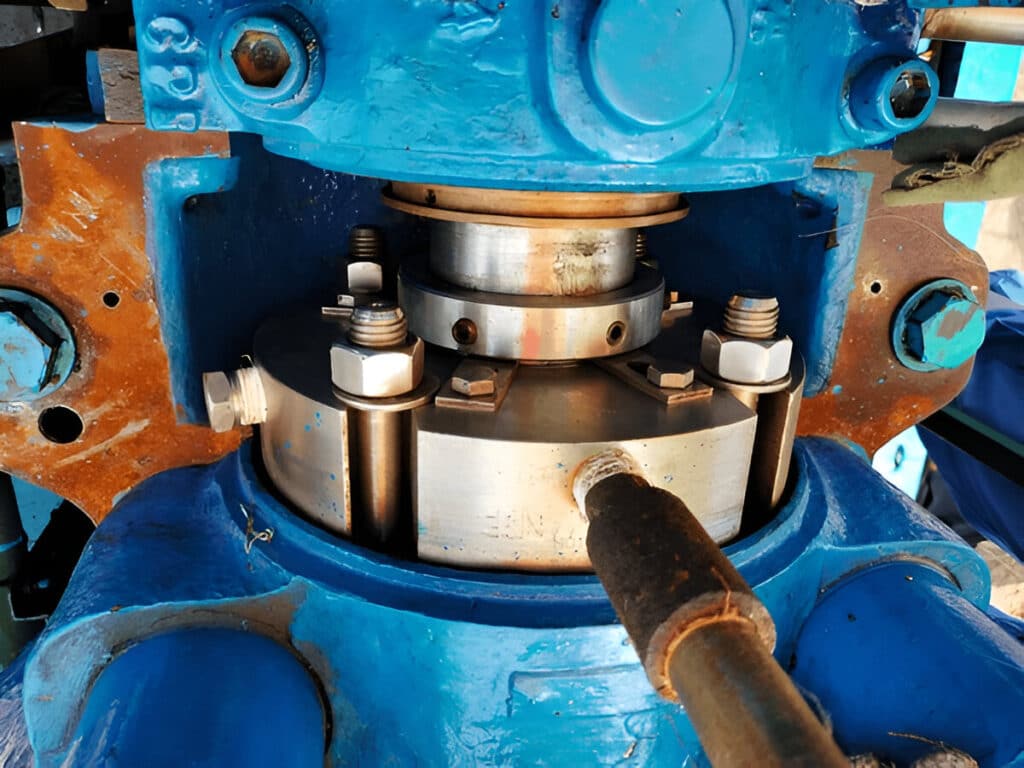

A cartridge mechanical seal is a preassembled, self-contained unit integrating all seal components into a single package including rotating and stationary faces, secondary seals, shaft sleeve, and gland housing. The entire assembly arrives factory-tested with preset spring compression locked in place by retaining clips.

Installation involves sliding the complete cartridge onto the shaft and bolting it to the pump. Once secured, you simply remove the setting clips to activate the seal at its predetermined spring force.

The integrated sleeve and gland plate eliminate the need for field measurements or adjustments. This drop-in design protects internal seal faces from contamination during handling and ensures consistent alignment every time.

What is the Difference between Component and Cartridge Mechanical Seals

Design

Component seals rely on the pump’s existing seal chamber and gland plate, requiring technicians to build the seal arrangement piece by piece on the equipment. Cartridge seals feature an integrated design with their own gland housing and shaft sleeve forming a complete assembly.

The fundamental difference is preassembly versus field assembly. Component seals offer greater customization flexibility since you can mix and match parts during installation, while cartridge seals provide standardized configurations optimized for specific pump models.

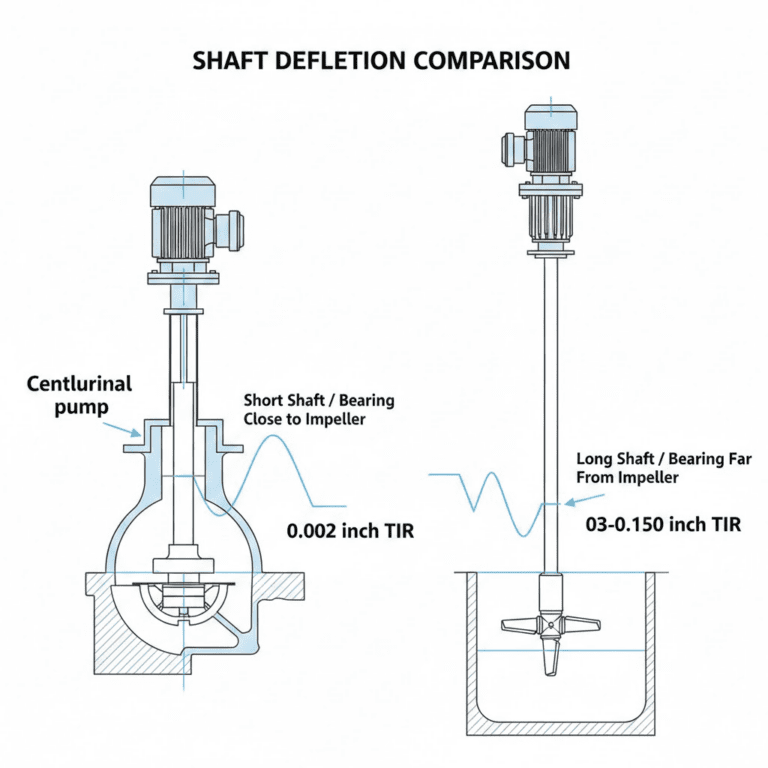

Cartridge units typically need more radial and axial space due to their integrated housing and sleeve. Component seals fit into tighter spaces and smaller seal chambers where a full cartridge assembly cannot physically fit.

Installation

Installing a component seal demands high technical skill and precise measurements to set correct spring compression and face alignment. Technicians must carefully slide individual parts over the shaft, avoiding damage to O-rings and seal faces while manually adjusting the working length.

Cartridge seals offer plug-and-play installation requiring no special measurements or field adjustments. The factory-set spring compression and alignment eliminate common installation errors that cause premature seal failure.

Installation time differs dramatically between the two types. A component seal replacement might take several hours of careful assembly, while a cartridge seal can be swapped in under an hour for most pumps.

Applications

Component seals dominate general-duty applications including water supply systems, HVAC equipment, light chemical service, and standard industrial pumps where initial cost matters more than installation speed. They remain the default choice for OEM pump packages and less critical services with infrequent maintenance intervals.

Cartridge seals are standard in continuous process industries like oil refining, petrochemicals, power generation, and pharmaceutical manufacturing where reliability and minimal downtime justify higher costs. The API 682 standard for petroleum industry pumps specifically recommends cartridge-style seals for hazardous services.

High-pressure and high-temperature applications typically require cartridge seals for their robust construction and factory-validated performance. Dual cartridge seals with barrier fluids provide zero-emission solutions for volatile organic compounds and toxic fluids.

Maintenance Requirements

Replacing a component seal requires significant pump disassembly to access the seal chamber and shaft area. Each part must be cleaned, inspected, and carefully reassembled with proper spring compression settings, often taking several hours of skilled labor.

Cartridge seals enable rapid replacement by removing the entire unit and inserting a new or refurbished cartridge without disturbing pump alignment. This process typically takes one-quarter the time of component seal replacement.

Component seals allow replacement of individual worn parts like faces or O-rings at minimal material cost if skilled labor is available. Cartridge seals must be replaced or refurbished as complete units but can be rebuilt off-site while the pump runs with a spare cartridge.

Cost

Component seals cost approximately one-third to one-half the price of equivalent cartridge seals initially. A typical ANSI pump component seal might cost a few hundred dollars while the cartridge version costs two to three times more.

How to choose the right seal

- Operating pressure above 200 psi: Choose cartridge seals for better pressure handling and balanced seal designs that prevent face distortion

- Extreme temperatures (below 0°F or above 400°F): Select cartridge seals with integrated cooling or heating provisions and factory-tested thermal tolerances

- Hazardous or toxic fluids: Use dual cartridge seals with barrier fluid systems to ensure zero emissions and compliance with environmental regulations

- Abrasive or slurry services: Pick cartridge seals with hardened faces and flush ports that simplify implementation of clean fluid injection

- Limited maintenance expertise: Choose cartridge seals to eliminate installation errors and reduce training requirements for maintenance staff

- Critical equipment with high downtime costs: Select cartridge seals for rapid replacement capability that minimizes production losses

- Small pumps or tight spaces: Use component seals when physical constraints prevent cartridge installation

- Budget-limited projects with skilled technicians: Choose component seals to minimize initial investment while leveraging in-house expertise

- Multiple pump standardization: Select cartridge seals for consistent performance across similar equipment and simplified spare parts management

- Compliance with industry standards: Use cartridge seals when API 682 or other specifications require them for your application

FAQs

Can any pump use a cartridge seal?

No, cartridge seals require adequate seal chamber space and must be installed from the dry side of the pump, making them unsuitable for some submersible pumps and older designs.

Which seal type lasts longer?

Cartridge seals often last longer due to consistent factory assembly and reduced installation errors, though properly installed component seals can achieve similar service life.

Do cartridge seals eliminate all installation errors?

Cartridge seals eliminate most common errors like incorrect spring compression and face misalignment, though proper shaft preparation and cartridge selection remain important.

What maintenance skills are needed for each type?

Component seals require experienced technicians familiar with seal assembly and measurement techniques, while cartridge seals can be installed by general maintenance personnel with basic mechanical skills.