Not all mechanical seals require seal water, but many do—it depends on what you’re pumping and the operating conditions. Clean, cool liquids often don’t need seal water, while hot, dirty, or abrasive fluids almost always do.

Think of seal water like engine coolant in your car. Just as your engine needs coolant to prevent overheating, mechanical seals handling tough applications need seal water to stay cool and clean.

What Exactly Is Seal Water?

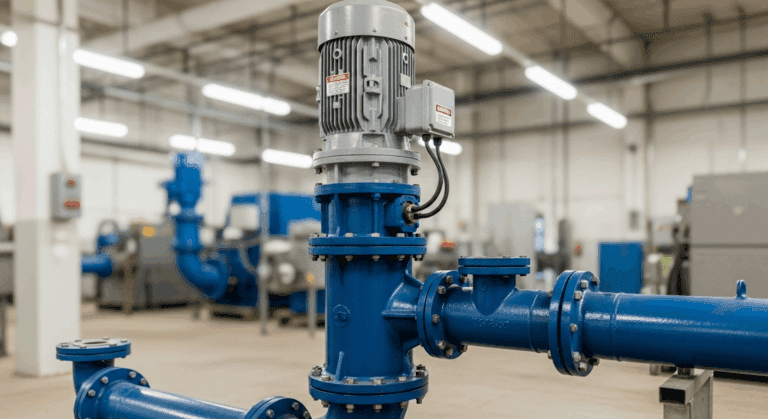

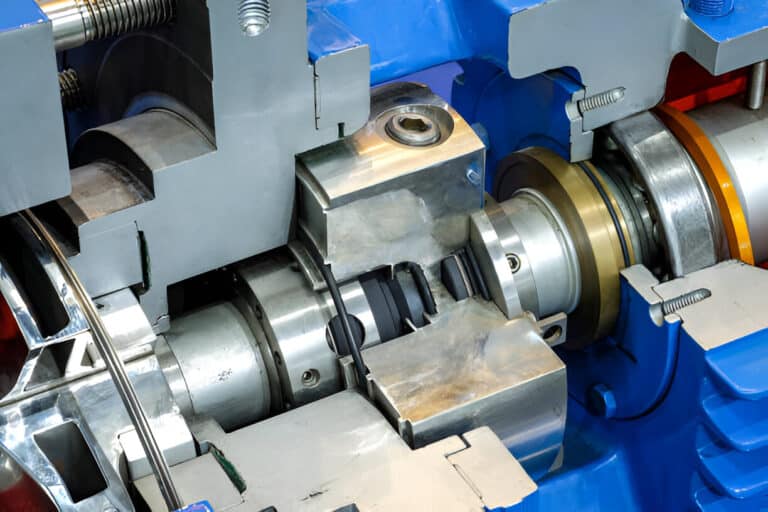

Seal water is any clean liquid—usually water, but sometimes oil or other fluids—that flows through or around a mechanical seal. Its main job is to protect the delicate seal faces that keep fluids from leaking out of pumps and other equipment.

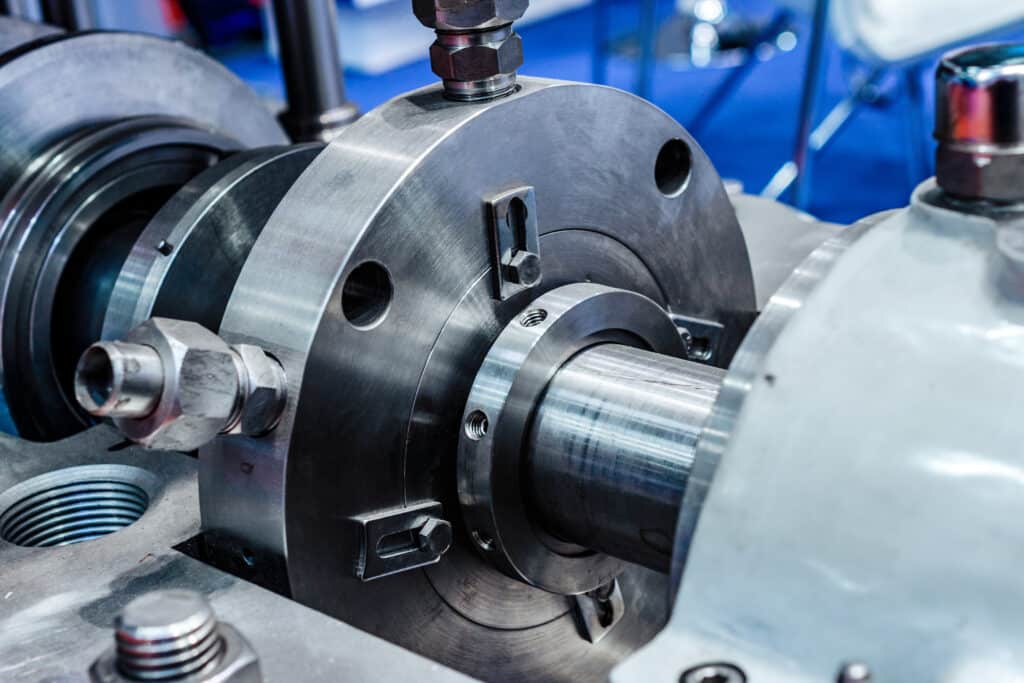

The liquid creates a thin film between the rotating and stationary parts of the seal. This film acts like a microscopic cushion, preventing the metal faces from grinding against each other and wearing out.

In most industrial settings, seal water comes from a dedicated clean water supply. It’s filtered, temperature-controlled, and sometimes treated with chemicals to prevent corrosion or bacterial growth.

How Does Seal Water Actually Work

Seal water enters the seal chamber through a port near the seal faces. It flows across the seal at a controlled rate, typically 0.5 to 2 gallons per minute, carrying away heat and debris before exiting through a drain port.

The water pressure must be carefully controlled—usually 10-15 PSI above the pump’s internal pressure. This ensures the clean water flows toward the dirty process fluid, not the other way around.

Some systems recirculate the same water through a cooling and filtering loop. Others use a “once-through” design where fresh water constantly flows in and used water drains away.

When Seal Water Is Absolutely Necessary

Hot liquids above 180°F (82°C) always require seal water. The flush water carries away excess heat before it can damage the seal faces or cause the liquid to vaporize between them.

Dirty or abrasive fluids also demand seal water. Picture trying to slide two pieces of glass together with sand between them—that’s what happens when particles get between seal faces without proper flushing.

Liquids that crystallize or solidify need constant flushing too. Sugar solutions, for example, will turn into rock-hard crystals on the seal faces without clean water washing them away.

When You Can Skip Seal Water

Clean, cool water at room temperature rarely needs seal water. The pumped liquid itself provides enough cooling and lubrication for the seal faces.

Light oils and many chemicals below 140°F (60°C) work fine without external flushing. The liquid film between the seal faces stays stable and provides adequate cooling.

Simple applications with non-critical fluids often run successfully without seal water. This saves money on piping, water consumption, and system complexity.

How to Determine Your Seal Water Needs

Start by checking your fluid temperature. Anything above 180°F automatically needs cooling, while anything below 140°F might not.

Next, evaluate fluid cleanliness. If you can see particles, expect crystallization, or know the fluid is abrasive, you need flush water.

Consider the consequences of seal failure. Critical applications often use seal water as insurance, even when it might not be strictly necessary.

FAQs

What happens if I run a mechanical seal without required seal water?

The seal will overheat and fail within hours or days. You’ll see increased leakage, damaged seal faces, and possibly secondary damage to the pump shaft and bearings.

How much seal water flow do I need?

Typically 0.5 to 2 gallons per minute for most applications. Your seal manufacturer provides specific recommendations based on seal size and operating conditions.

Can I use the pumped product instead of clean water for flushing?

Yes, if the product is clean, cool, and compatible with the seal materials. This is called Plan 11 and works well for many clean water and light hydrocarbon applications.

Can seal water freeze in cold climates?

Yes, and it will destroy your seal immediately. In freezing conditions, you need heat tracing, glycol solutions, or continuous flow to prevent ice formation.