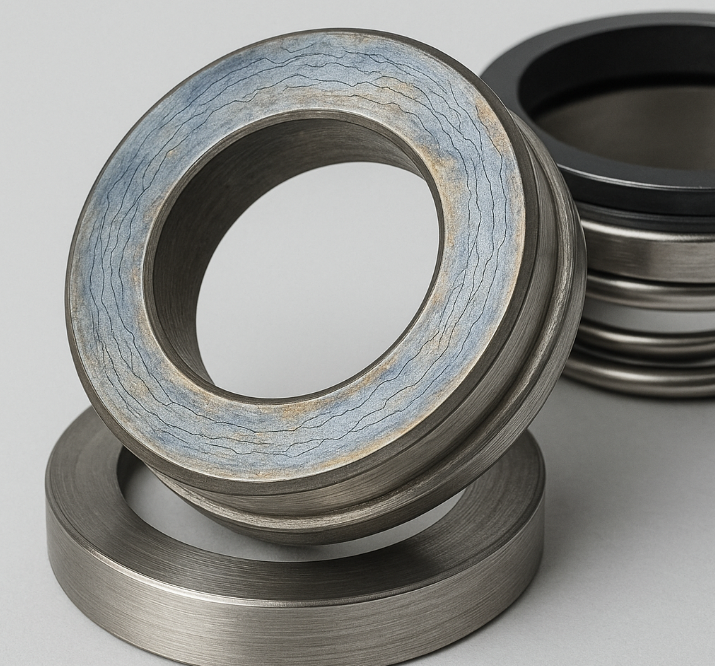

Heat checking happens when mechanical seal faces crack in a radial pattern due to extreme temperature changes and thermal stress. These cracks look like spokes on a wheel, starting from the center and extending outward, ultimately causing the seal to fail prematurely.

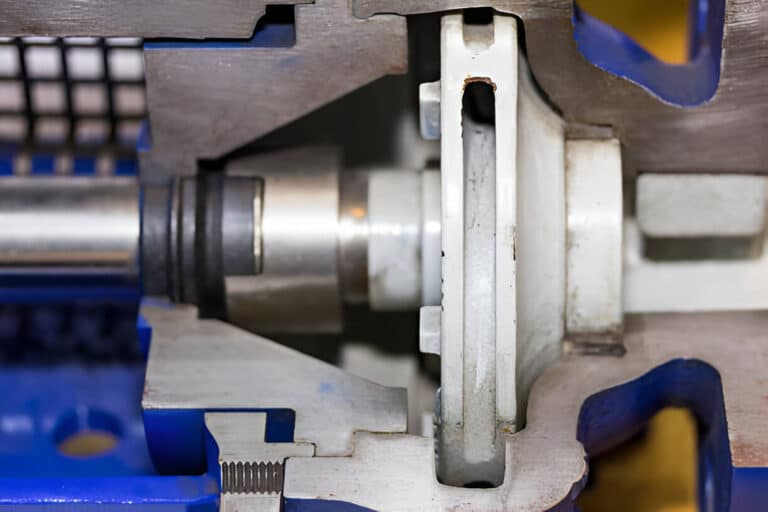

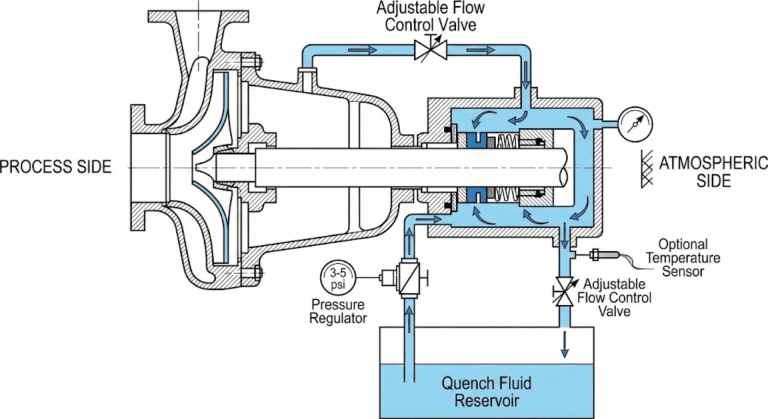

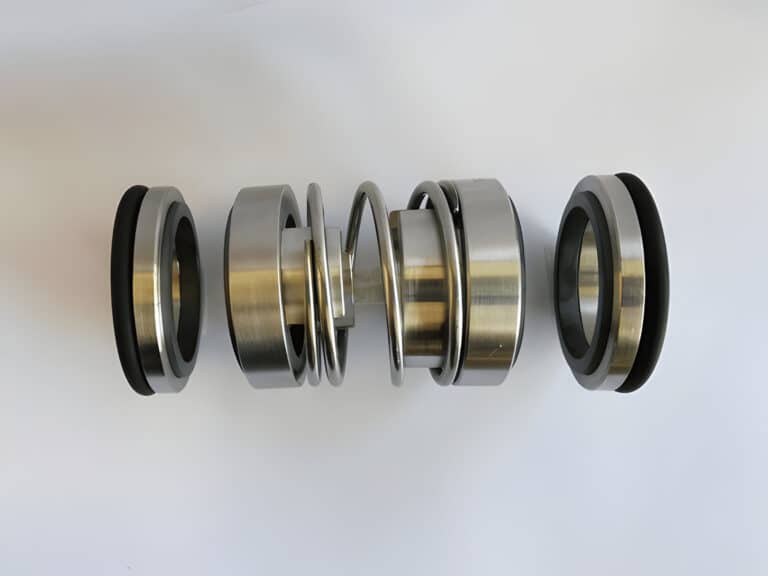

Mechanical seals prevent fluid from leaking where a rotating shaft passes through a pump casing. They work by pressing two incredibly smooth faces together – one rotates with the shaft while the other stays stationary. A microscopically thin film of fluid between these faces provides lubrication and cooling.

When this protective fluid film disappears or temperatures spike, the seal faces expand and contract at different rates. Hard materials like tungsten carbide and ceramics can’t handle these rapid temperature swings, so they crack under the stress.

How Thermal Stresses Develop in Seal Faces

Thermal stresses build up when seal faces heat unevenly and then cool too quickly. The temperature differences across the face material create internal forces that eventually exceed what the material can handle.

- Frictional heating: When seal faces rub together without proper lubrication, friction generates intense heat at contact spots. The spring force and hydraulic pressure pressing the faces together make this worse. Without enough fluid film between the faces, temperatures can spike to several hundred degrees in seconds.

- Viscous shear and fluid dynamics: High-speed rotation combined with thick fluids creates tremendous shearing forces in the thin film. This shearing action generates heat just like rubbing your hands together. When pressure and velocity get too high, the fluid film actually heats up enough to cause the seal face to warp into a cone shape.

- Differential expansion: Different parts of the seal face expand at different rates when heated. The inner diameter near the shaft gets much hotter than the outer edge. Since materials like tungsten carbide have high stiffness but poor thermal shock resistance, they can’t flex to accommodate these differences – so they crack instead.

- Thermal shock: The most damaging scenario occurs when a hot seal face suddenly meets cold fluid. Picture dropping a hot glass dish into cold water – it shatters. The same thing happens to seal faces when they’re running hot and dry, then suddenly get flushed with cool liquid. The rapid contraction creates tensile stresses that produce the characteristic radial crack pattern.

Causes and Operating Conditions That Lead to Heat Checking

Several operating conditions can trigger heat checking, but they all share one thing in common – they create extreme temperature conditions that the seal material can’t handle.

Dry Running and Loss of Lubrication

Dry running is the number one cause of heat checking because it eliminates the cooling and lubricating fluid film between the faces.

- Lack of fluid film: Starting a pump without liquid or losing flush flow leaves the seal faces rubbing metal-on-metal. Without fluid to carry heat away, temperatures skyrocket within seconds. When fluid finally returns, the thermal shock cracks the hot faces instantly.

- Inadequate lubrication: High-viscosity fluids or incorrect barrier fluids don’t flow properly between the faces. Cold weather can thicken fluids to the point where they can’t maintain the protective film. The faces might not be completely dry, but they’re not getting enough lubrication to prevent overheating.

- Dry running due to vaporisation or flashing: Operating too close to a liquid’s boiling point causes it to flash to vapor at the seal interface. The seal faces suddenly lose their liquid film and run dry. This happens frequently with hot water applications or when pumps cavitate, creating localized low-pressure zones where liquid turns to vapor.

Poor Cooling and High Temperature

Even with adequate lubrication, insufficient cooling allows heat to build up until the seal faces crack.

- Insufficient cooling/flush flow: Blocked flush lines, scaled heat exchangers, or pump failures in the seal support system prevent proper cooling. Heat generated at the faces has nowhere to go. The temperature keeps climbing until thermal stresses exceed the material’s strength and cracks form.

- High product temperature: Pumping hot oil, steam condensate, or other high-temperature fluids exposes seals to constant heat. The seal faces operate close to their maximum temperature rating. Any additional heat from friction or process upset pushes them over the edge into heat checking territory.

- Thermal cycling: Repeated hot-cold cycles fatigue the seal material. Starting with hot product then flushing with cold water creates massive temperature swings. Each cycle weakens the material until cracks finally appear. It’s like bending a paperclip back and forth until it breaks.

High Pressure and Velocity (PV) Limits

Every seal material has a maximum PV rating – the product of pressure and surface velocity it can handle. Exceeding this limit generates excessive heat through friction.

Operating above 200,000 psi-ft/min dramatically increases face temperature and wear rate. The combination of high speed and high pressure creates more friction than the fluid film can dissipate. The faces heat up progressively until thermal cracking occurs.

Cavitation

Cavitation creates violent bubble collapses that generate localized hot spots on seal faces. When fluid pressure drops below vapor pressure, bubbles form and then implode against the seal faces.

These implosions create microscopic areas of extreme heat and pressure. The repeated thermal stress from thousands of bubble collapses per second eventually produces the radial crack pattern characteristic of heat checking.

Cavitation also causes vibration that disrupts the fluid film between faces. This leads to intermittent dry running conditions that compound the thermal stress problem.

Air Entrainment and Pressure Spikes

Air pockets and pressure surges interrupt the steady conditions seals need to operate properly. Trapped air in the stuffing box creates dry spots where the faces touch without lubrication.

Pressure spikes during startup or process upsets suddenly increase the load on seal faces. This extra pressure squeezes out the fluid film, causing momentary metal-to-metal contact and rapid heating.

The combination of air pockets and pressure variations creates unpredictable hot spots that stress the seal faces. Over time, these repeated thermal shocks produce the telltale radial cracks of heat checking.

FAQs

Can heat-checked seals be repaired?

No, heat-checked seal faces cannot be repaired and must be replaced. The cracks compromise the seal’s ability to maintain a proper fluid film and will cause progressive damage to the mating face.

How quickly can heat checking occur?

Heat checking can happen in seconds during severe dry running or within hours under marginal conditions. The speed depends on temperature extremes and how quickly the seal faces heat up and cool down.

What seal materials are most resistant to heat checking?

Silicon carbide generally offers the best heat checking resistance due to its excellent thermal conductivity. Carbon-graphite materials also perform well because they can handle thermal shock better than hard ceramics.

How can I prevent heat checking in my pump seals?

Ensure proper flush flow, never run pumps dry, maintain correct fluid temperatures, and operate within the seal’s PV limits. Installing temperature monitors and automatic shutdown systems provides extra protection against conditions that cause heat checking.