What Is Inside-mounted Mechanical Seal

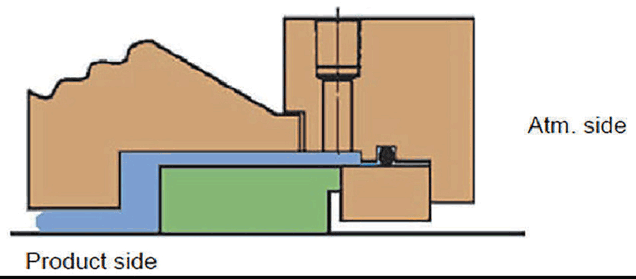

An inside-mounted mechanical seal, also known as an internal seal, is a type of mechanical seal designed to be installed inside the equipment being sealed, such as a pump or compressor. This seal arrangement positions the seal chamber and its components within the equipment housing, providing a compact and space-efficient solution for sealing rotating shafts.

Inside-mounted mechanical seals are designed to contain process fluids within the equipment, preventing leakage to the environment. The seal faces are perpendicular to the shaft and create a narrow gap between the stationary and rotating components. A thin fluid film is maintained within this gap, lubricating the seal faces and minimizing wear while preventing leakage.

Advantages of Inside-mounted Mechanical Seal

- Lower initial cost: Inside-mounted seals have a simpler design compared to outside-mounted seals, making them more affordable.

- Easy installation: The seal can be installed directly into the pump casing or seal chamber, reducing the need for additional components and simplifying the installation process.

- Compact design: Inside-mounted seals require less space, making them suitable for applications with limited room for seal installation.

- Suitable for low-pressure applications: The simple design of inside-mounted seals is adequate for low-pressure systems, where the process fluid provides sufficient lubrication and cooling for the seal faces.

Disadvantages of Inside-mounted Mechanical Seal

- Limited pressure and speed capabilities: Inside-mounted seals may not be suitable for high-pressure or high-speed applications due to their simpler design and reliance on the process fluid for lubrication.

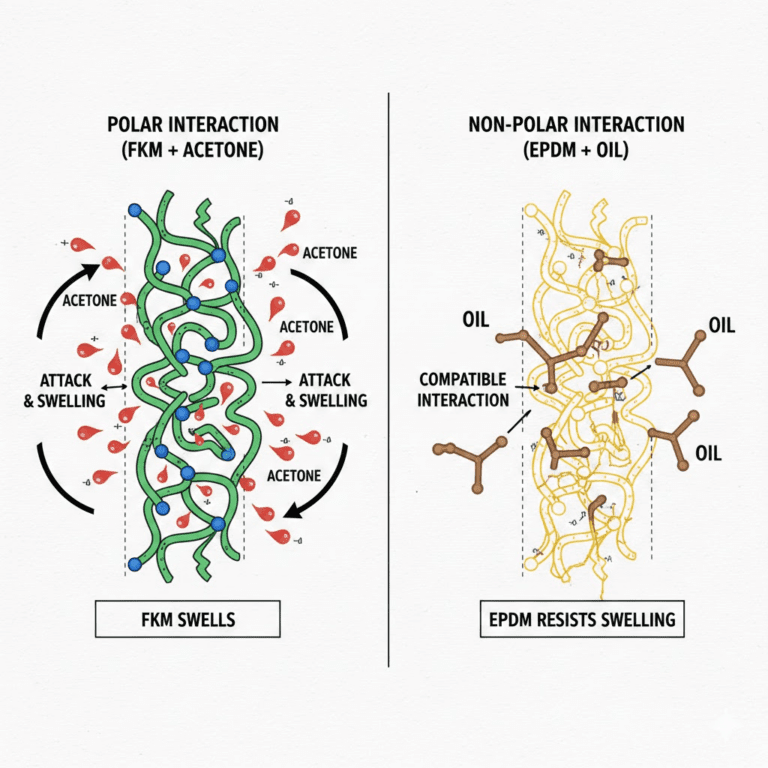

- Dependent on process fluid for lubrication: The seal faces rely on the process fluid for lubrication and cooling, which can be problematic if the fluid is abrasive, corrosive, or contains solids that can damage the seal faces.

- Shorter seal life in challenging conditions: In applications with harsh process fluids or high temperatures, inside-mounted seals may experience premature wear and shorter seal life compared to outside-mounted seals.

- Less flexibility in seal face materials: The choice of seal face materials may be limited due to the direct exposure to the process fluid, which can restrict the use of inside-mounted seals in certain applications.

What Is Outside-mounted Mechanical Seal

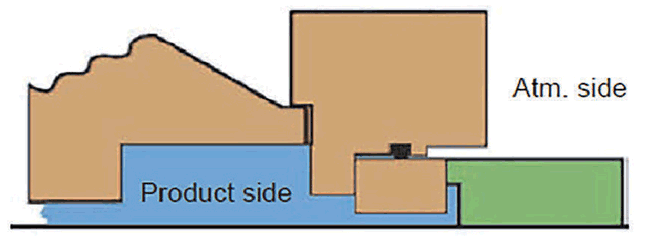

An outside-mounted mechanical seal, also referred to as an outboard seal, is a type of seal that is installed external to the pump housing or seal chamber. In this configuration, both the stationary and rotating components of the seal are mounted outside the pump casing. This arrangement allows for the use of a barrier fluid or buffer fluid to lubricate and cool the seal faces, providing better control over the sealing environment.

Outside-mounted seals are commonly used in applications where the process fluid is unsuitable for direct contact with the seal faces, such as in highly abrasive, corrosive, or high-temperature environments. They are also used in systems that require a higher level of sealing performance or reliability, such as in critical processes or environmentally sensitive applications.

Advantages of Outside-mounted Mechanical Seal

- Improved seal face lubrication: The use of a barrier or buffer fluid ensures proper lubrication and cooling of the seal faces, reducing wear and extending seal life.

- Enhanced seal face materials selection: With the seal faces isolated from the process fluid, a wider range of materials can be used, allowing for better optimization of seal performance based on application requirements.

- Increased pressure and speed capabilities: Outside-mounted seals can handle higher pressures and rotational speeds compared to inside-mounted seals due to the improved lubrication and cooling provided by the barrier or buffer fluid.

- Better control over sealing environment: The barrier or buffer fluid can be pressurized and circulated through a heat exchanger, providing better control over the sealing environment and reducing the impact of process fluid variations on seal performance.

- Longer seal life in challenging conditions: With improved lubrication and the ability to select optimal seal face materials, outside-mounted seals can provide longer service life in harsh applications.

Disadvantages of Outside-mounted Mechanical Seal

- Higher initial cost: The additional components and complexity of outside-mounted seals make them more expensive than inside-mounted seals.

- Increased space requirements: The external mounting of the seal components requires more space around the pump, which may be a limitation in certain installations.

- More complex installation and maintenance: The presence of additional components, such as barrier fluid systems and heat exchangers, makes the installation and maintenance of outside-mounted seals more complex compared to inside-mounted seals.

- Potential for barrier fluid contamination: If the barrier fluid system is not properly maintained or if there are issues with the auxiliary components, the barrier fluid can become contaminated, leading to reduced seal performance or failure.

When to Use Inside-mounted Mechanical Seal

- Clean, non-abrasive fluids: When the process fluid is relatively clean and does not contain abrasive particles that can damage the seal faces.

- Low-pressure systems: Inside-mounted seals are suitable for low-pressure applications where the process fluid can provide adequate lubrication and cooling for the seal faces.

- Mildly corrosive environments: In applications with mildly corrosive fluids, inside-mounted seals can be used with appropriate seal face materials that can withstand the process conditions.

- Limited space availability: When there are space constraints around the pump, inside-mounted seals can be a compact solution.

- Cost-sensitive applications: For applications where the initial cost is a primary concern, inside-mounted seals can be a more affordable option compared to outside-mounted seals.

When to Use Outside-mounted Mechanical Seal

Here’s the content reformatted as a list with bolded key points in English:

- Abrasive or corrosive fluids: When the process fluid contains abrasive particles or is highly corrosive, outside-mounted seals with a suitable barrier or buffer fluid can protect the seal faces from damage.

- High-temperature processes: In applications with high process temperatures, outside-mounted seals can provide better cooling and temperature control for the seal faces through the use of a heat exchanger in the barrier fluid system.

- High-pressure or high-speed applications: Outside-mounted seals are capable of handling higher pressures and rotational speeds compared to inside-mounted seals due to the improved lubrication and cooling provided by the barrier or buffer fluid.

- Environmentally sensitive processes: In applications where seal leakage can have severe environmental consequences, outside-mounted seals with a dual seal arrangement or a containment seal can provide an additional layer of protection.

- Critical processes requiring high reliability: For applications where seal reliability is of utmost importance, outside-mounted seals with advanced features such as non-contacting seal faces, active monitoring, and control systems can provide enhanced performance and longer seal life.