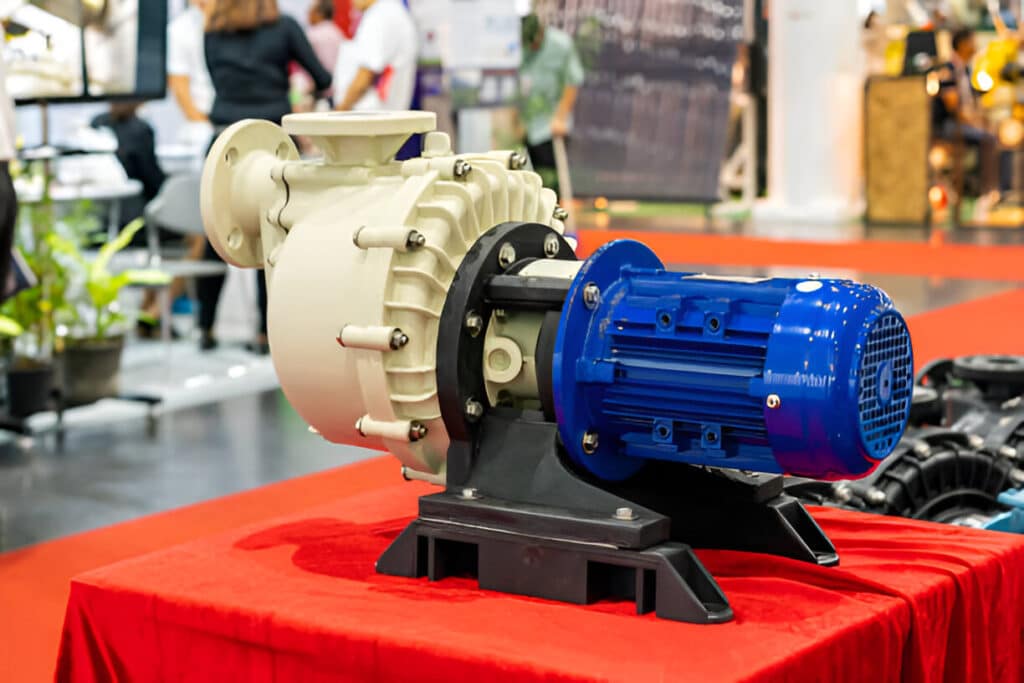

Using a mechanical seal for muddy river water might seem unconventional, but it could be a game-changer.

In this blog post, we’ll explore how this innovative approach can effectively combat the challenges posed by contaminated water.

Discover the benefits and potential applications that could revolutionize water treatment and infrastructure.

Muddy River Water Characteristics

Muddy river water is a complex mixture of various components, including water,d solids, dissolved minerals, and organic matter. The composition and properties of muddy water can vary significantly depending on factors such as the river’s location, surrounding geology, climate, and human activities in the watershed.

Density: The presence of suspended solids increases the density of muddy water compared to clear water. This increased density can affect the flow characteristics of the water and the settling behavior of the suspended particles.

Abrasiveness: The suspended particles in muddy water can be abrasive, causing wear and tear on pumps, pipes, and other equipment that comes into contact with the water.

Chemical reactivity: The suspended solids and dissolved minerals in muddy water can interact with each other and with other substances, such as pollutants or water treatment chemicals, affecting the water’s chemical properties and treatment requirements.

Challenges of Using Mechanical Seals in Muddy River Water

Abrasive Particles

Muddy river water contains a high concentration of abrasive particles like sand, silt, and small rocks. These particles can quickly wear down and damage the sealing faces of mechanical seals, leading to leaks and premature failure. The constant exposure to these abrasives can significantly reduce the lifespan of the seals.

Clogging and Buildup

The high levels of suspended solids in muddy water can cause clogging and buildup within the mechanical seal assembly. This can restrict the flow of the lubricating fluid, causing the seal faces to run dry and overheat. The buildup can also prevent the seal from maintaining proper contact, resulting in leaks.

Corrosion and Chemical Reactions

Depending on the specific composition of the muddy river water, it may contain chemicals or compounds that can corrode or react with the materials used in the mechanical seal. This can lead to degradation of the seal components, weakening their structure and compromising their sealing ability.

Fluctuating Operating Conditions

River water levels and flow rates can vary significantly depending on factors like rainfall, upstream activities, and seasonal changes. These fluctuations can impact the pressure and velocity of the water passing through the mechanical seal, making it challenging to maintain consistent sealing performance. Sudden changes in operating conditions can cause the seal faces to shift or lose contact, resulting in leaks.

Maintenance and Monitoring

Using mechanical seals in muddy river water applications often requires more frequent monitoring and maintenance compared to cleaner water sources. The seals may need to be inspected, cleaned, and replaced more often to ensure they continue to function effectively. This can increase operational costs and downtime for the system.

How to Choose the Right Mechanical Seals

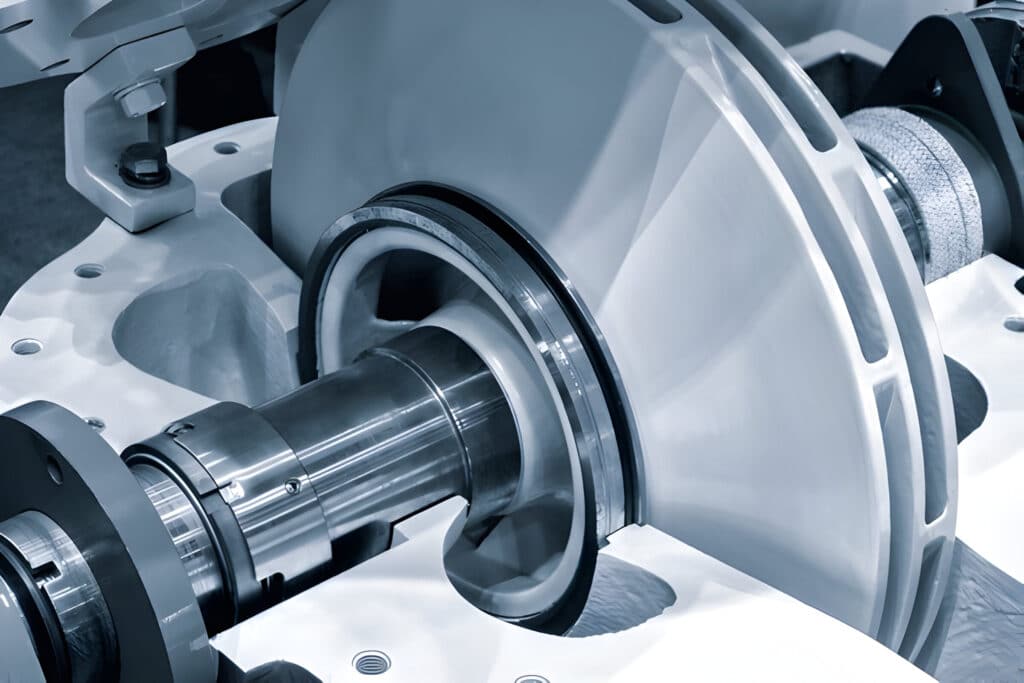

Material Compatibility

For applications involving muddy river water, it is critical to choose seal materials that can handle abrasive conditions and potential chemical exposure.

Suitable materials for seal faces include silicon carbide, tungsten carbide, and diamond-coated surfaces, while Viton, EPDM, and Kalrez are recommended for elastomers due to their excellent resistance to abrasion and chemical attack.

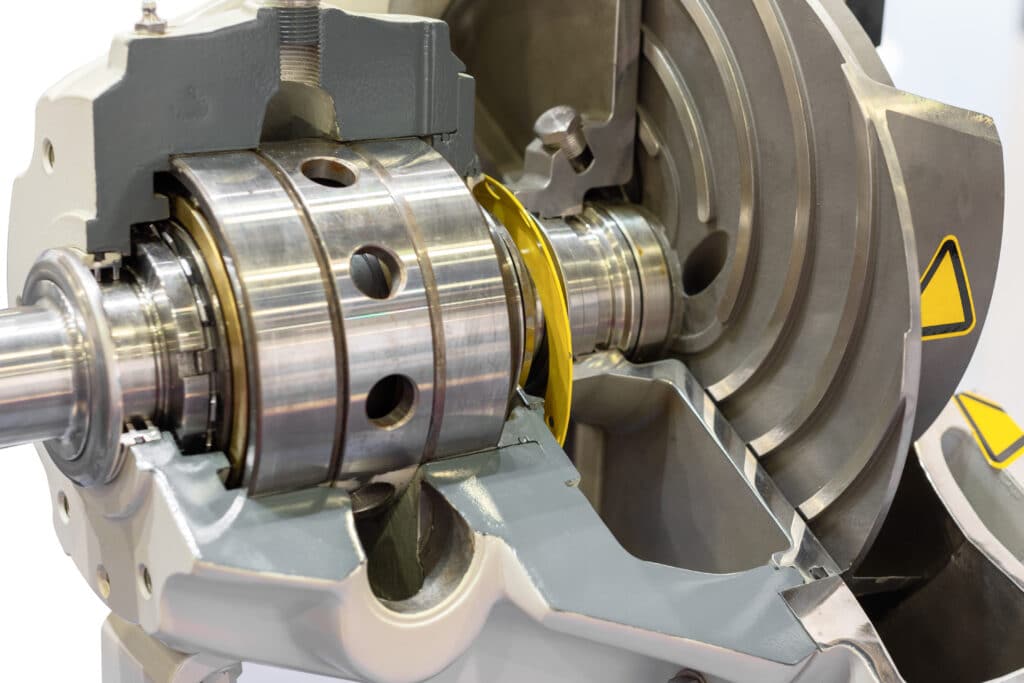

Seal Arrangement

In environments like muddy river water, a double seal arrangement is preferable over a single seal. This configuration features a barrier fluid positioned between two seals, enhancing lubrication and cooling while keeping abrasive particles at bay. A plan 53B arrangement, which uses a pressurized barrier fluid reservoir, is often advocated under these demanding conditions.

Seal Design

Bellows seals is ideal for muddy river water due to their flexibility and lower risk of clogging. Seals should have larger faces and be made from harder materials to boost durability and wear resistance.

Flushing and Cooling

Implementing an efficient flushing and cooling system can preserve the mechanical seals. Systems like cyclone separators or sediment traps can be used in the flushing line to filter out abrasive particles.

It is also important to ensure the compatibility of the flushing fluid with both the seal materials and the muddy river water.

Monitoring and Maintenance

Utilizing a condition monitoring system that tracks temperature, pressure, and vibration can help in early detection of issues, facilitating prompt maintenance actions.

A systematic maintenance schedule should also be established, including routine inspections, cleaning, and replacement of components as necessary.

Conclusion

In conclusion, using a mechanical seal for muddy river water can provide an effective solution to prevent contamination and ensure system reliability.

By investing in high-quality mechanical seals, we can safeguard our water systems and promote a cleaner environment.

Take action now and explore mechanical seal options for your water management needs.