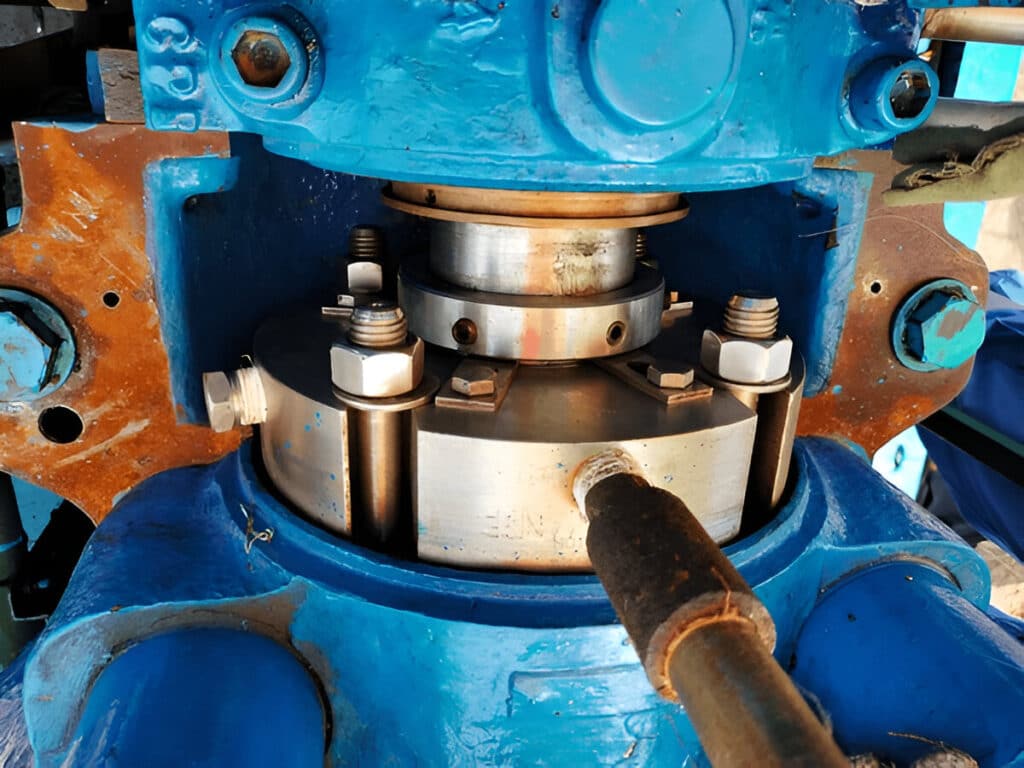

Double mechanical seals comprise several essential components that work together to provide optimal sealing performance. The main parts include two sets of primary seal faces, a barrier fluid area, an environmental control system, secondary sealing elements, and metal hardware components.

Two Set of Primary Seal Faces

In double mechanical seals, you’ll find two sets of primary seal faces: rotating and stationary. The rotating faces are attached to the shaft and spin with it, while the stationary faces remain fixed to the housing. These paired faces work together to create a tight seal, preventing leakage and ensuring the proper functioning of the mechanical seal system.

Rotating faces

Rotating faces, also known as double primary seal faces, form critical components in double mechanical seals. These faces consist of hard, wear-resistant materials like silicon carbide or tungsten carbide. They mount on the rotating shaft or sleeve, spinning with it during operation.

Double mechanical seals incorporate two sets of rotating faces, one for each seal. These faces work with stationary faces to create the sealing interface. As they spin, rotating faces maintain a thin fluid film between themselves and the stationary faces.

Stationary faces

Stationary faces complement their rotating counterparts. These fixed elements remain immobile within the seal assembly, typically mounted on the seal gland or housing. Manufacturers craft stationary faces from durable materials like silicon carbide, tungsten carbide, or carbon, designed to withstand high pressures and temperatures while maintaining seal integrity.

The face surface undergoes precision polishing to achieve an extremely fine finish, minimizing friction and wear when contacting the rotating face.

Barrier/Buffer Fluid Area

You’ll find the barrier/buffer fluid area between the two sets of seal faces in a double mechanical seal. This space is filled with either barrier fluid (for pressurized systems) or buffer fluid (for unpressurized systems). The fluid serves essential functions: it lubricates and cools the seal faces, prevents process fluid from leaking, and can indicate seal performance through monitoring.

Barrier fluid

Barrier fluid circulates between the two seal faces in double mechanical seals, providing lubrication, cooling, and pressure. This clean, compatible liquid or gas prevents process fluid from escaping to the atmosphere, ensuring proper seal function.

Maintaining the barrier fluid at a higher pressure than the process fluid guarantees effective sealing. This pressure differential prevents process fluid from leaking into the barrier fluid area.

Buffer fluid

Buffer fluid occupies the space between inboard and outboard seals in a double mechanical seal system. It lubricates seal faces, reducing friction and wear while extending their lifespan. Heat dissipation is another key role, preventing thermal distortion and maintaining consistent seal performance.

The buffer fluid creates a barrier at a lower pressure than the process fluid against process fluid leakage. It contains small amounts that might escape past the inboard seal, preventing environmental contamination and product loss. Water, oil, or glycol-based solutions are common choices.

Environmental Control System

Environmental control systems include heat exchangers, thermostats, pressure regulators, and filters.

Heat exchangers remove excess heat generated by seal friction, preventing overheating and fluid degradation.

Thermostats monitor and control buffer fluid temperature, triggering cooling or heating to maintain the desired range.

Pressure regulators maintain the correct pressure differential between buffer and process fluids. This prevents contamination and ensures proper seal operation.

Filters remove contaminants from the buffer fluid, extending its life and protecting seal faces from damage.

Secondary Sealing Elements

Secondary sealing elements prevent leakage between stationary and rotating parts in double mechanical seals.

O-rings, the most common type, offer versatility and reliability. Made of elastomers, they conform to irregular surfaces, providing excellent sealing in various applications.

Gaskets serve a similar purpose but are flat and designed for specific shapes. They are often used between flanges or in static applications.

V-rings, also known as lip seals, are V-shaped elastomeric seals that provide dynamic sealing against rotating shafts. They excel at excluding contaminants and retaining lubricants.

Bellows are flexible, accordion-like structures that absorb axial movement and vibration. They are used in high-pressure or corrosive environments where traditional elastomeric seals might fail.

Metal Hardware Components

Metal hardware components form the structural backbone of double mechanical seals.

Gland plates house and protect the seal assembly, made of corrosion-resistant materials with ports for cooling, flushing, or barrier fluid circulation. These plates maintain proper seal face alignment and pressure.

Retainers secure stationary seal components, preventing rotation with the shaft. They often incorporate anti-rotation pins or tabs. Drive mechanisms, such as pins or keys, transmit torque from the rotating shaft to the rotating seal face, ensuring synchronous movement.

Springs maintain constant contact between seal faces, compensating for wear, thermal expansion, and pressure fluctuations. Coil springs and wave springs are common in double mechanical seals.

FAQs

How Often Should Double Mechanical Seals Be Replaced?

Double mechanical seals typically require replacement every 3-5 years.

Can Double Mechanical Seals Be Repaired Instead of Replaced?

Double mechanical seals can often be repaired rather than replaced.

What Are the Typical Costs Associated With Double Mechanical Seal Maintenance?

Double mechanical seal maintenance costs vary significantly, ranging from hundreds to thousands of dollars. Factors influencing expenses include seal size, complexity, and required repairs.

Are There Alternatives to Double Mechanical Seals for High-Pressure Applications?

Alternatives to double mechanical seals for high-pressure applications include magnetic drive pumps, canned motor pumps, and hermetically sealed pumps.

How Do Temperature Fluctuations Affect the Performance of Double Mechanical Seals?

Temperature fluctuations impact double mechanical seals by causing expansion or contraction of seal face materials. This alters seal gaps, potentially affecting sealing effectiveness and increasing wear.