Common Causes of Mechanical Seal Failure

- Improper installation: Incorrect alignment, inadequate lubrication, or damage during installation can lead to seal failure.

- Excess heat generation: High operating temperatures, insufficient cooling, or dry running conditions can cause seals to overheat and fail.

- Chemical attack: Exposure to corrosive or incompatible fluids can degrade seal materials, leading to leakage and failure.

- Mechanical issues: Excessive vibrations, shaft misalignment, or improper seal chamber pressure can cause premature wear and failure.

- Incorrect seal selection: Choosing the wrong seal material or design for the specific application can result in suboptimal performance and failure.

6 Ways to Prevent Seal Failure

Choose the Correct Seal

Consider factors such as the operating environment, process fluid, and pump design when choosing a seal material and configuration. For example, in applications involving high temperatures or corrosive fluids, opt for materials like silicon carbide or carbon seal faces. Balanced seals are suitable for high-pressure applications, while cartridge seals simplify installation and maintenance. Consult with seal manufacturers or experienced maintenance teams to determine the optimal seal combination for your specific application.

Failure to choose the correct seal can lead to seal damage, excessive wear, and premature failure. Improper seal selection may result in incompatibility with the process fluid, inability to withstand the operating conditions, or inadequate lubrication. These issues can cause costly downtime and increased maintenance costs. To avoid these problems, carefully assess your application requirements and environmental conditions before selecting a seal design.

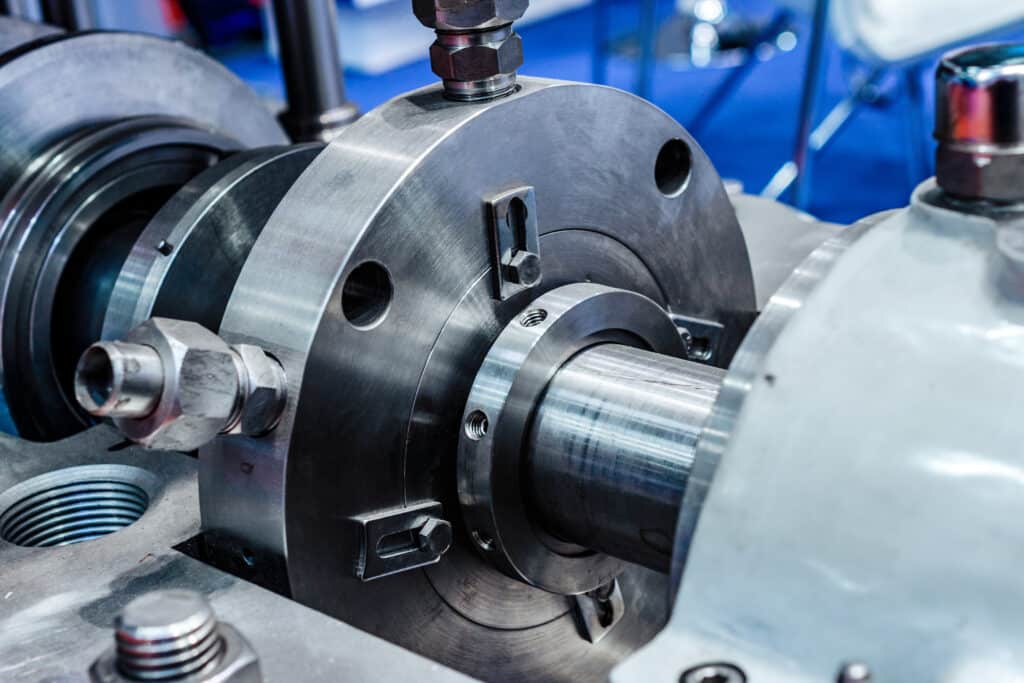

Properly Install the Seal

Follow the manufacturer’s installation procedures closely, paying attention to factors such as seal alignment, shaft concentricity, and seal chamber dimensions. Ensure that the sealing surfaces are clean and free from damage or debris. Lubricate the seal faces and secondary seals according to the manufacturer’s recommendations. When installing cartridge seals, take care not to damage the seal components during handling and installation.

Improper seal installation can lead to premature failure, fluid leakage, and increased wear. Common installation errors include misalignment, incorrect compression, and damage to sealing surfaces. These issues can cause uneven wear, excessive heat generation, and seal leakage. To prevent these problems, provide thorough training to maintenance personnel and follow established installation procedures. Double-check the seal alignment and condition before starting the pump.

Prevent Excess Heat Generation

Heat can be generated by factors such as dry running, poor lubrication, misalignment, and debris in the seal chamber. To prevent heat-related failures, ensure that the seal is properly lubricated by the process fluid or an external fluid source. Maintain the recommended seal chamber pressure and flow rate to provide adequate cooling and lubrication. Address any misalignment issues promptly to prevent excessive vibration and heat generation.

Implementing a flush plan or seal support system can help control heat generation and extend seal life. API Plan 11 (formerly API Plan 01) recirculates the process fluid from the pump discharge to the seal chamber, providing cooling and lubrication. For high-temperature applications or fluids with poor lubricating properties, consider dual seal arrangements such as API Plan 53A or Plan 54. These plans use an external fluid source to cool and lubricate the seals, reducing the risk of heat-related failures.

Maintain Proper Storage Conditions

Store seals in a clean, dry, and temperature-controlled environment, away from direct sunlight and potential contaminants. Keep elastomeric components such as O-rings and secondary seals in their original packaging to prevent degradation. Rotating seal faces should be stored vertically to prevent damage to the lapped surface. Ensure that the specified storage life of elastomeric components is not exceeded, and replace any components that show signs of damage or degradation before installation.

Improper storage conditions can lead to various issues, such as seal face damage, elastomer degradation, and corrosion of metal components. These issues can result in premature failure, fluid leakage, and increased maintenance costs. To prevent storage-related failures, establish proper storage protocols and train personnel on the correct handling and storage of mechanical seals.

Unrestricting Seal Motion

Ensuring that the mechanical seal can move freely within the specified axial and radial tolerances is crucial for optimal performance. Restriction of seal motion can occur due to factors such as shaft misalignment, excessive shaft deflection, and buildup of solid particles in the seal chamber. These issues can lead to uneven wear, increased heat generation, and premature failure.

To prevent restricted seal motion, maintain proper shaft alignment and address any misalignment issues promptly. Ensure that the pump shaft is within the specified runout and concentricity tolerances. Regular vibration monitoring can help detect misalignment and excessive shaft deflection early. In applications involving abrasive or high-solids fluids, consider using cyclone separators, filters, or Eddy current separators to remove solid particles from the process fluid before it enters the seal chamber.

Protecting Seal Materials

Mechanical seal materials can degrade over time due to various factors, including chemical attack, abrasive wear, and thermal stress. To protect seal materials and extend seal life, select materials that are compatible with the process fluid and can withstand the operating conditions. For example, silicon carbide and tungsten carbide are highly resistant to abrasive wear, while fluoroelastomers such as Viton and Kalrez offer excellent chemical resistance.

In applications involving corrosive or aggressive fluids, consider using dual seal arrangements with a barrier fluid that is compatible with the seal materials. This helps to isolate the seal faces from the process fluid and extend seal life. Regular monitoring of the barrier fluid pressure and condition can help detect seal leakage or fluid contamination early.