You’ve probably never thought much about seal support systems. Most people haven’t. But if you’re running industrial equipment—pumps, compressors, mixers—these systems might be the difference between smooth operations and costly failures.

Here’s the reality: mechanical seals fail. When they do, your equipment stops. Downtime means lost production, emergency repairs, and frustrated teams scrambling to fix things. Seal support systems exist to prevent exactly this scenario.

A seal support system is an auxiliary system designed to provide a controlled environment for mechanical seals operating in rotating equipment. Think of it as life support for your seals. It supplies fluid (either liquid or gas) to keep the seal faces cool, lubricated, and protected from the harsh process fluids your equipment is handling.

What is a Seal Support System

Definition and Core Purpose

A seal support system is an auxiliary system designed to provide a controlled environment for mechanical seals. Its job is to supply a buffer or barrier fluid (gas or liquid) to the mechanical seal, regulating pressure, temperature, and flow conditions.

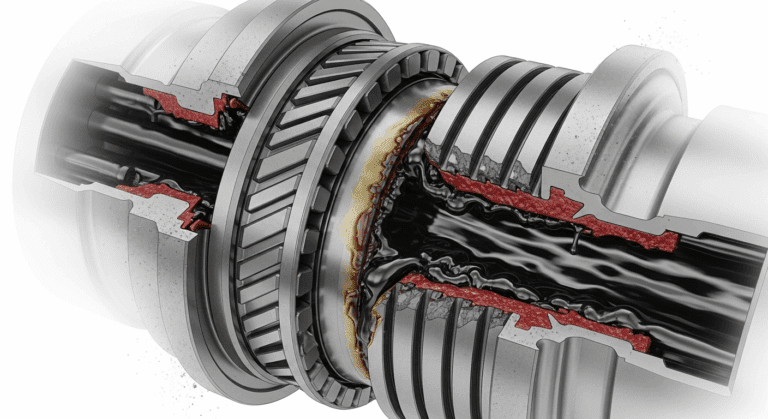

Mechanical seals create a barrier between a rotating shaft and the equipment housing. Two extremely flat, lapped surfaces are pressed together—one rotates with the shaft, the other stays stationary. Between them sits an ultra-thin fluid film that lubricates the faces and keeps them cool. Without proper support, this film breaks down. Friction increases. Heat builds up. The seal fails.

That’s what seal support systems prevent.

Why Mechanical Seals Need Support Systems

Let me explain why this matters with a simple scenario. Imagine a pump moving aggressive chemical process fluid at high pressure. Without a seal support system, the process fluid would try to force its way past the mechanical seal. The seal faces would rub together, generating extreme heat. The fluid film would evaporate. The seal faces would wear and eventually fail.

Now add a seal support system. It circulates clean, cool barrier fluid at precisely controlled pressure into the seal chamber. This creates a protective shield between the process fluid and the rotating equipment. The seal faces stay cool. The fluid film stays intact. Your equipment keeps running.

Core Functions of Seal Support Systems

Seal support systems accomplish several critical functions:

Provide Clean Lubrication. The ultra-thin fluid film between seal faces needs to be perfectly clean. Any particles—dirt, rust, scale—will scratch the seal faces and cause failure. Seal support systems circulate filtered, conditioned fluid to maintain this pristine lubrication layer.

Remove Heat. Seal face friction generates heat. Without cooling, seal chamber temperatures climb quickly. Excessive temperatures are one of the top two reasons mechanical seals fail. Seal support systems circulate fluid through coolers or reservoirs to dissipate this heat.

Control Pressure Differentials. The pressure inside the seal chamber must be carefully balanced. Too much pressure and you push the seal faces apart. Too little and process fluid leaks past. Seal support systems maintain the correct pressure differential to keep the seal working properly.

Manage Contamination. Process fluids are hostile environments. They contain particles, corrosive compounds, and temperature extremes. Seal support systems prevent this hostile process fluid from contaminating the seal chamber.

How Do Seal Support Systems Work?

The Mechanical Seal and Fluid Film

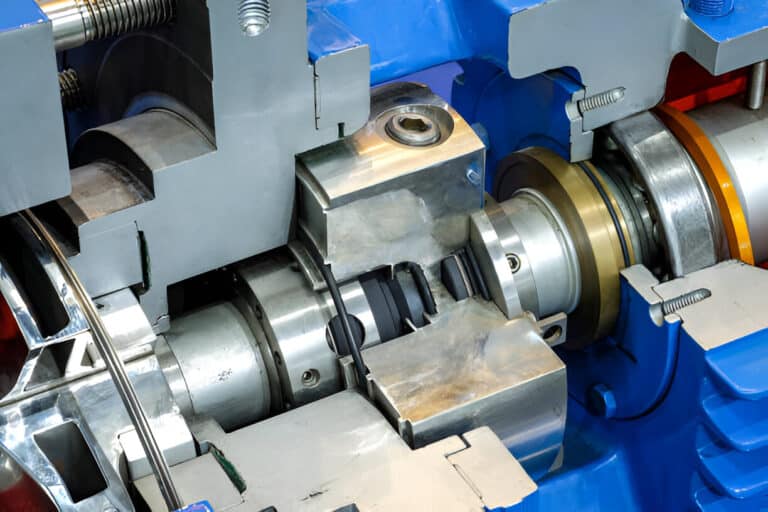

To understand seal support systems, you need to understand what they’re protecting. A mechanical seal has two main components:

- A rotating element attached to the shaft

- A stationary element held in the equipment housing

These elements have precisely lapped surfaces that are extremely flat—typically polished to near-optical quality. When the shaft rotates, these flat surfaces stay in close contact, separated only by an incredibly thin fluid film (often just microns thick).

This fluid film does the heavy lifting. It lubricates the surfaces, carries away heat, and creates a seal that prevents process fluid from leaking past. It’s elegant and fragile at the same time.

System Components and Their Functions

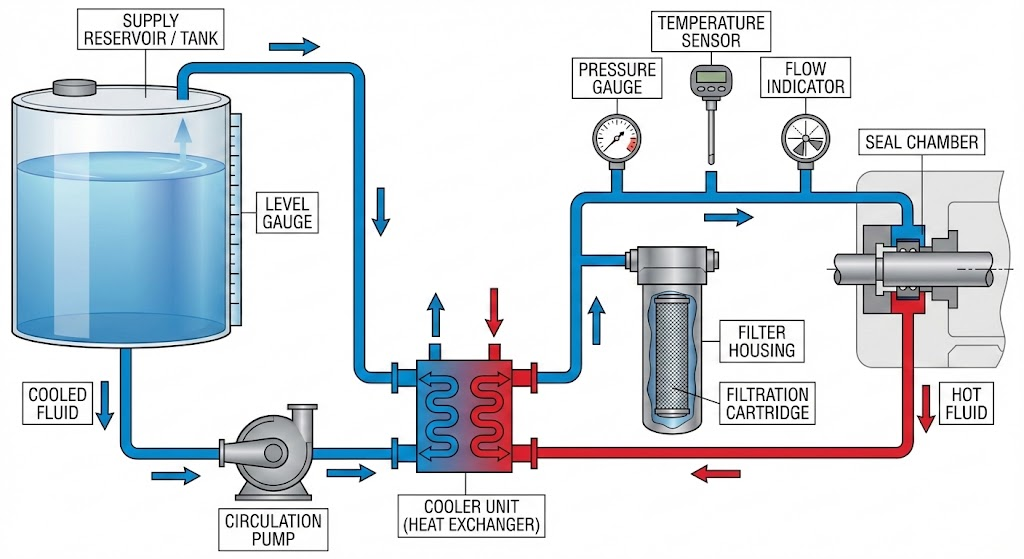

A seal support system has several key components working together:

The Supply Reservoir or Source. This holds the support fluid (buffer or barrier fluid). It maintains a steady supply of clean, cool fluid to the seal chamber.

Circulation System. Pumps move support fluid through the system at a controlled flow rate. This circulation removes heat and maintains pressure.

Cooling Equipment. If the process generates significant heat, a cooler removes heat from the support fluid before it returns to the seal chamber. Without this cooling, seal temperatures climb.

Filtration. Filters remove particles from the support fluid. Clean fluid is essential for seal longevity.

Monitoring and Control Devices. Pressure gauges, temperature sensors, and flow indicators monitor system performance. Regulators maintain the correct pressure and flow.

Piping and Connections. These components direct fluid to and from the seal chamber at precisely the right pressure, temperature, and flow rate.

All these components work together to create and maintain the perfect operating environment for your mechanical seal. The API 682 industry standard defines specific configurations for different applications.

What Are the Main Types of Seal Support Systems?

API 682 Piping Plans Overview

The American Petroleum Institute (API) created standard API 682 to guide mechanical seal support system design. This standard defines numbered “Piping Plans”—essentially standardized configurations for different operating conditions.

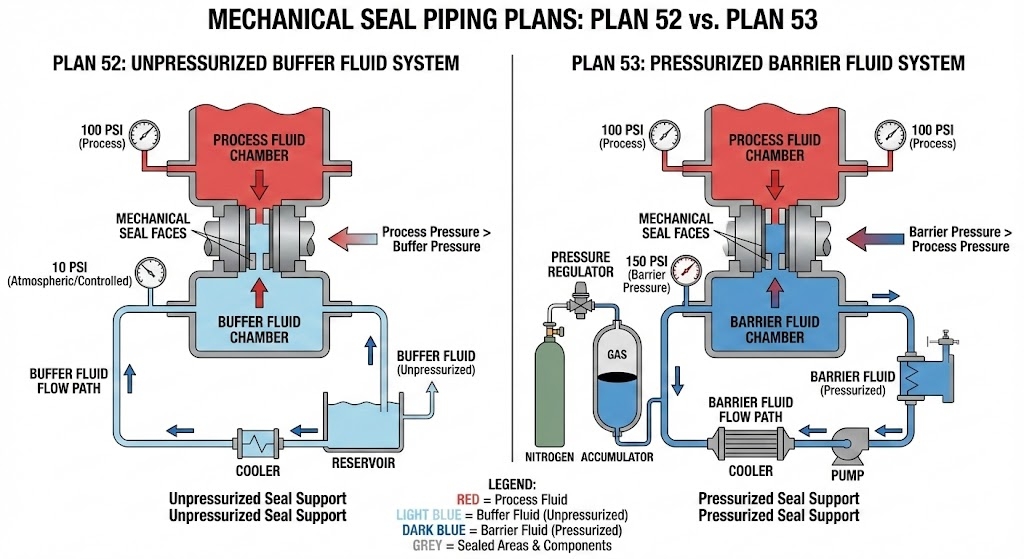

The most common plans are Plan 52 (Buffer Systems) and Plan 53 (Pressurized Barrier Systems). The plan you choose depends on your process fluid, pressure, temperature, and environmental requirements.

Plan 52: Buffer Fluid System

A Plan 52 system supplies unpressurized buffer fluid into the seal chamber. Think of the buffer fluid as a shield between your process fluid and the mechanical seal.

Here’s how it works: The buffer fluid sits in the seal chamber at approximately the same pressure as your process fluid. This buffer separates the aggressive process fluid from the sensitive seal chamber environment. The buffer fluid circulates continuously to remove heat and carry away any contamination.

Plan 52 systems work well when:

- Your process fluid is mildly aggressive or moderately hazardous

- You want environmental protection (preventing process fluid leakage)

- Your process pressure is moderate

- You need a cost-effective solution

The main limitation is that buffer fluid can gradually become contaminated with process fluid over time. Plan 52 systems require regular monitoring and occasional buffer fluid replacement.

Plan 53: Pressurized Barrier Fluid System

A Plan 53 system maintains a pressurized barrier fluid at higher pressure than your process fluid. This higher pressure actively prevents process fluid from entering the seal chamber.

Here’s the key difference from Plan 52: The barrier fluid pressure is higher than process pressure. This creates an active seal that keeps aggressive process fluids away from the mechanical seal. The barrier fluid circulates through a more complex system that includes pressure regulators and accumulators to maintain the precise pressure differential.

Plan 53 systems are necessary when:

- Your process fluid is extremely aggressive or hazardous

- You have high-pressure conditions

- Environmental regulations require zero leakage

- You need the ultimate in seal protection

Plan 53 systems cost more than Plan 52, but they provide superior protection for demanding applications. The added complexity and monitoring requirements are justified when you’re dealing with toxic, corrosive, or valuable process fluids.

Additional Support System Categories

Beyond Plans 52 and 53, seal support systems can be categorized by where they’re applied relative to the mechanical seal:

Process-Side Systems. Support fluid comes from the process side (inside the pump). These work for compatible fluids.

Atmospheric-Side Systems. Support fluid is supplied from outside the equipment. These work for incompatible or hazardous process fluids.

In-Between Systems (Dual Seals). Support fluid sits between two mechanical seals. This provides maximum protection for dual-seal configurations.

Seal Support Systems in Different Industries

Oil and Gas Operations

Oil and gas operations deal with high pressures, high temperatures, and sometimes-aggressive process fluids. Mechanical seals in these environments need serious protection.

A typical offshore crude oil pump might see temperatures up to 80°C, pressures exceeding 100 bar, and process fluids containing corrosive compounds. Without proper seal support systems, seals would fail in days or weeks.

With proper Plan 53 barrier systems, the same equipment runs reliably for months between seal replacements. The upfront system cost is small compared to the cost of an emergency offshore helicopter repair mission.

Chemical Processing

Chemical plants handle everything from mild water solutions to extremely aggressive hydrocarbons and caustics. Process fluids might be toxic, expensive, or both.

Seal support systems serve two critical functions here: They protect the environment (preventing hazardous releases) and they protect the seals (preventing failures that damage expensive equipment).

Many chemical processors mandate API 682 Plan 53 systems for anything handling hazardous materials. The compliance requirement forces good sealing practice.

Water Treatment and Utilities

Water treatment facilities pump everything from raw source water to treated finished water to process chemicals. Seal support systems keep these critical operations running reliably.

Water utilities often use plan 52 buffer systems with treated water as the buffer fluid. This provides simplicity while still offering significant reliability improvement.