A small leak in an agitator can cost you thousands in wasted product, emergency repairs, and unplanned downtime. I’ve seen chemical plants shut down for days because a seal failed and nobody had a backup plan. The worst part? Most of these failures are preventable with the right equipment and knowledge.

An agitator mechanical seal is a dynamic sealing device that prevents process fluid leakage while allowing your agitator shaft to rotate freely.

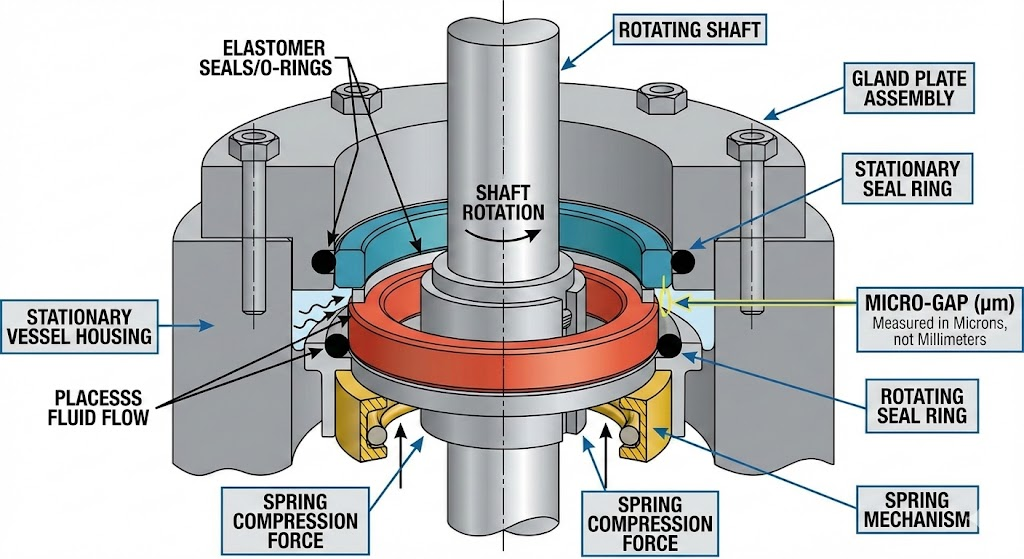

An agitator mechanical seal stops fluid from leaking where the rotating shaft passes through the vessel wall. Instead of using old-fashioned packing glands that need constant adjustment and tightening, mechanical seals create a permanent, dynamic barrier between two precisely machined surfaces.

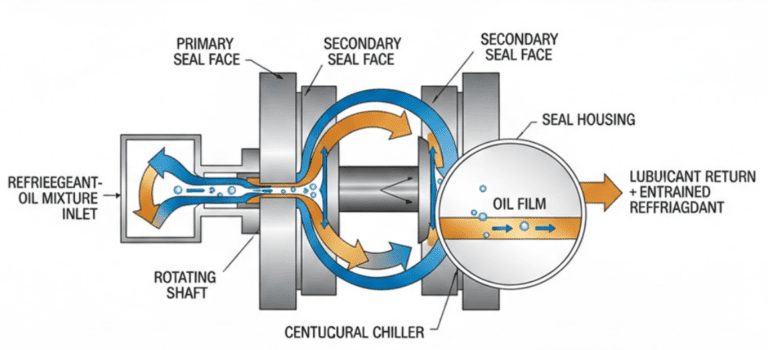

Here’s why this matters: when your agitator shaft spins, the rotating seal ring moves with it. The stationary seal ring stays fixed to the housing. A thin film of your process fluid naturally forms between these two surfaces, creating a nearly frictionless seal. This design reduces shaft wear, cuts maintenance costs, and handles extreme pressures and temperatures that would destroy older sealing methods.

Types of Agitator Mechanical Seals

Not all mechanical seals are created equal. Your application demands a specific type, and choosing wrong leads to failures and wasted money.

Single vs. Double Mechanical Seals

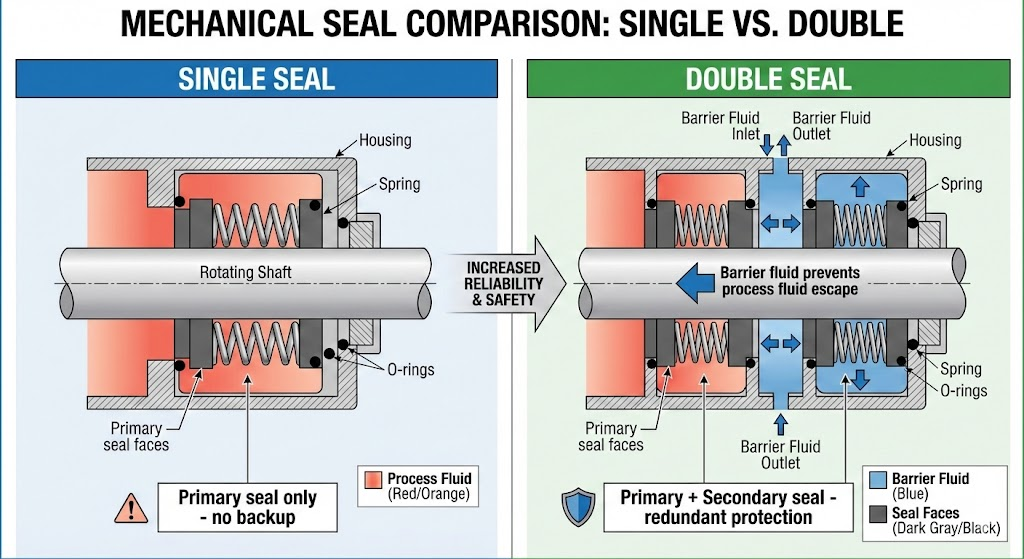

Single mechanical seals work great for non-hazardous applications like water treatment or mild chemical mixing. They’re simpler, cheaper, and easier to install. If your process fluid isn’t toxic and you can tolerate minor leakage, a single seal saves money upfront.

But single seals have a significant weakness: no backup. If that one seal fails, fluid leaks immediately.

Double mechanical seals eliminate this risk. They consist of two sets of sealing surfaces arranged in series, with a barrier fluid between them. If your primary seal fails, the secondary seal keeps working. This redundancy makes double seals essential for toxic chemicals, pharmaceutical manufacturing, and high-pressure processes.

The tradeoff? Double seals cost several hundred to several thousand dollars more than singles. You’ll also need monitoring systems to track barrier fluid status and seal chamber pressure. Installation and maintenance are more complex. But when you’re handling hazardous materials or protecting expensive products, that extra cost becomes negligible compared to the risk.

Installation Configuration Options

Your vessel design and maintenance access determine which installation type makes sense.

Top Entry Seals install from above the mixing tank. This is the most common configuration because you can replace the seal without draining the tank. Maintenance crews love top entry seals because they’re accessible and familiar. Most new agitators come with top entry designs.

Side Entry Seals mount on the vessel sidewall. This configuration saves tank space (important when your vessel is tall and narrow) and requires minimal tank drainage for seal replacement. Chemical plants often prefer side entry for space-constrained installations.

Bottom Entry Seals install at the tank bottom. You see these primarily in applications involving highly viscous fluids or abrasive slurries where top or side mounting isn’t practical. They create an extremely compact design, but they’re less common and require more careful installation.

Each configuration has the same basic seal mechanism. The difference is purely about where the seal mounts and how you access it for maintenance.

Selecting the Right Seal for Your Application

Choosing the wrong seal is a false economy. You might save $500 upfront but lose $50,000 in downtime and replacement costs. Let me walk you through the selection process.

Critical Selection Factors

Start with temperature. Your seal material must handle your maximum operating temperature plus a safety margin. Carbon seals typically handle up to 300°F, while ceramic materials push past 400°F. If your vessel sees thermal cycling—heating up and cooling down repeatedly—select materials with similar thermal expansion rates to prevent warping.

Pressure and speed determine seal design. Higher pressures require stronger spring systems and more robust materials. Faster shaft speeds generate more friction and heat, so material selection becomes even more critical. Most agitator seals operate between 500-3000 RPM, but heavy-duty industrial agitators can spin faster.

Your process fluid properties matter enormously. Highly viscous fluids (like heavy oils or resins) require different seal designs than thin, watery fluids. Abrasive slurries with suspended particles demand harder seal faces. pH levels affect elastomer selection—acidic or alkaline fluids can destroy incompatible rubber materials in weeks.

Chemical compatibility is non-negotiable. A seal rated for water will fail catastrophically in organic solvents. Always consult your seal manufacturer’s compatibility matrix before ordering. When in doubt, request samples tested against your specific fluid.

Leakage requirements vary by application. Some industries tolerate minor seepage (a few drops per hour) and use low-cost barrier systems. Pharmaceutical and food manufacturing demand virtually zero leakage. If you need tight containment, plan on double seals or specialized barrier fluid systems.

Installation space constraints often determine your options. Some vessels have limited clearance above or around the shaft. Top entry might be impossible. Side entry might be your only option. Check your vessel dimensions and mounting configurations before specifying a seal type.

Cost Comparison Considerations

Single mechanical seals typically cost $200-$1,000 depending on materials and specifications. A basic carbon-vs-silicon carbide seal runs around $400.

Double mechanical seals cost $1,000-$3,000+. You’re paying for two seal systems plus the barrier fluid circulation infrastructure. Add another $500-$1,000 for the monitoring equipment.

Material selection drives cost dramatically. A carbon seal might run $300, while a tungsten carbide seal for the same application costs $800+.

But don’t optimize for lowest initial cost. Include total cost of ownership: purchase price plus installation labor, barrier fluid (if needed), maintenance time, and the cost of downtime when seals fail. A $300 seal that fails every 18 months and shuts down production for 2 days might cost you $30,000 annually. A $1,500 seal lasting 3-5 years might only cost $3,000 annually including maintenance.

Making Your Selection

You now understand what mechanical seals do, how they work, what types exist, and what problems to avoid. The final question is simple: which seal does your application need?

Start with honesty about your process. What are you mixing? What’s the temperature, pressure, and speed? Do you need hermetic containment, or can you tolerate minor leakage? What’s your budget for initial purchase and ongoing maintenance?

If you’re mixing non-hazardous fluids in a simple batch process, a single seal with carbon-vs-silicon carbide faces is probably your best choice. It’s affordable, proven, and requires minimal maintenance.

If you’re handling toxic chemicals, pharmaceutical products, or food-grade materials, double seals become essential. The redundancy and monitoring capability justify the extra cost.

When in doubt, consult with seal manufacturers directly. Send them your process fluid sample and operating parameters. They’ll recommend the best seal for your specific situation and often provide samples for testing before you commit to a large purchase.

The cheapest seal isn’t the best seal. The right seal is the one that keeps your process safe, minimizes downtime, and proves economical over its complete lifespan. That’s the only calculation that matters.