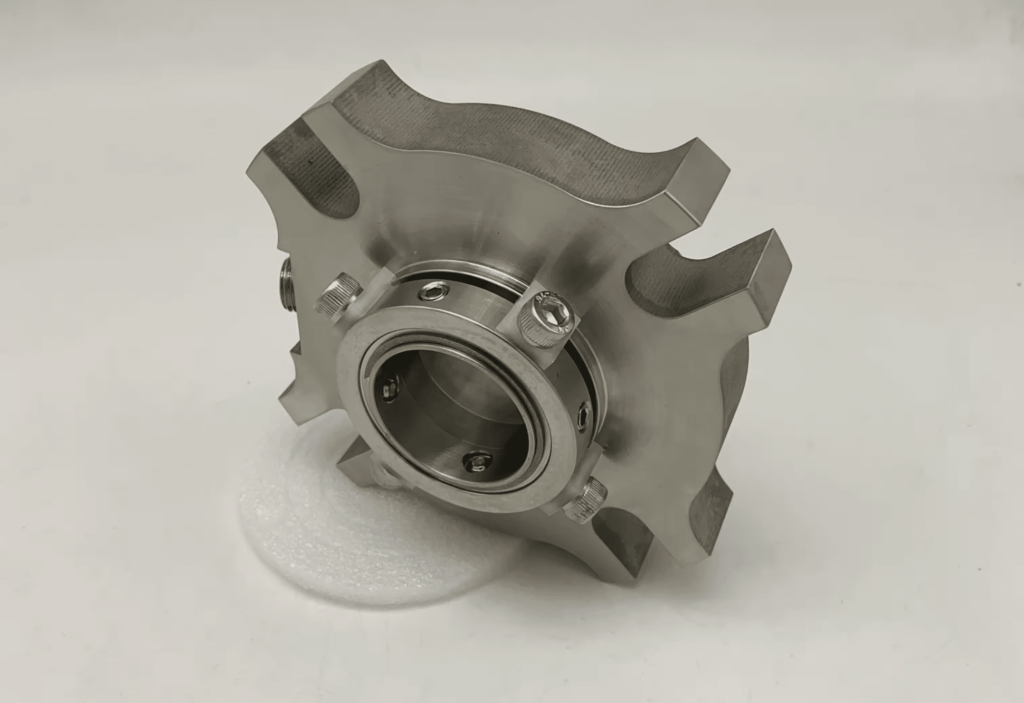

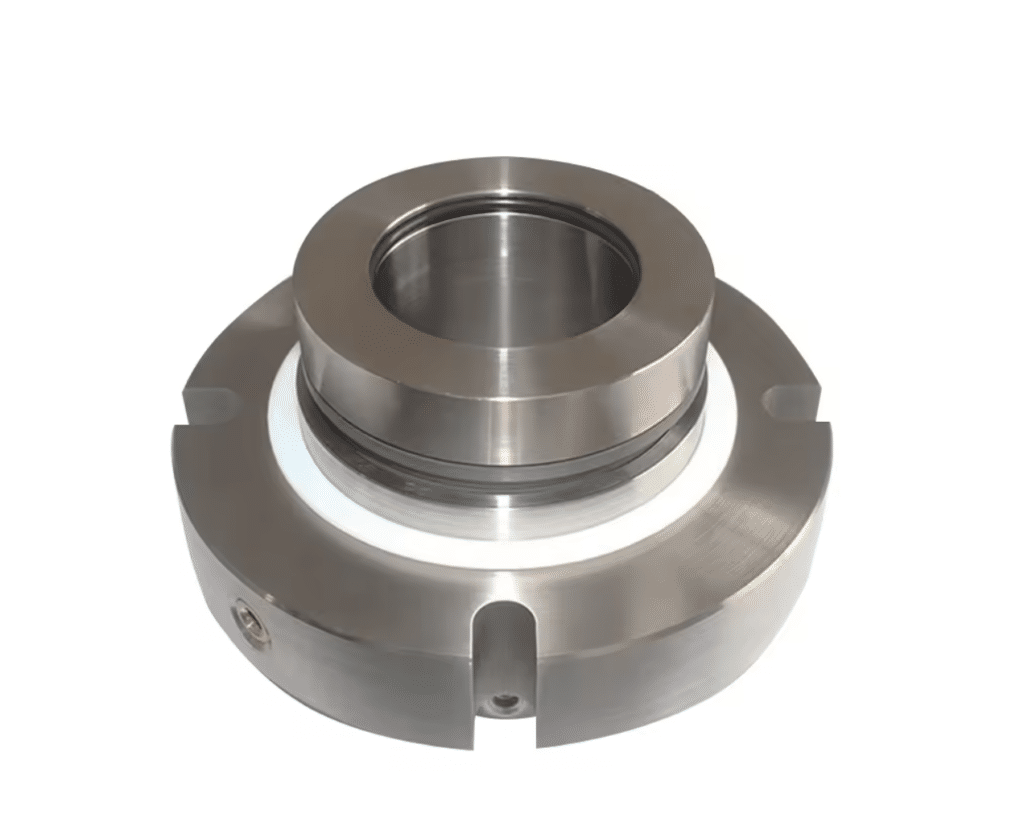

A cartridge mechanical seal is a pre-assembled sealing unit that prevents leaks in pumps and rotating equipment. Unlike traditional component seals that arrive as separate parts, cartridge seals come as one complete package with all components already aligned and set by the manufacturer.

This self-contained design includes the seal faces, sleeve, gland housing, springs, and all necessary hardware in a single unit that slides onto the pump shaft. The main advantage is simplicity – installers don’t need to measure spring compression or worry about precise alignment since everything is preset at the factory.

Industries from oil refineries to water treatment plants rely on these seals because they reduce installation errors and equipment downtime while providing reliable leak prevention for critical fluids.

What Is Cartridge Mechanical Seal

A cartridge mechanical seal is essentially a complete mechanical seal assembly that comes ready to install. Think of it as the difference between buying furniture that needs assembly versus furniture that arrives fully built.

The seal contains all the same components as a traditional mechanical seal but packaged together in one convenient unit. The manufacturer pre-mounts everything on a sleeve with its own gland plate, ensuring perfect alignment and proper spring compression.

This design eliminates the guesswork that comes with assembling individual seal parts in the field. When a technician receives a cartridge seal, they’re getting a tested, calibrated unit that just needs to be slid onto the shaft and bolted in place.

How Does Cartridge Mechanical Seal Work

The working principle centers on two ultra-flat faces that rotate against each other to create a seal. One face attaches to the rotating shaft while the other stays fixed to the pump housing.

When the pump runs, these precision-lapped faces slide against each other with only a microscopic film of fluid between them. This thin fluid layer lubricates the faces to prevent overheating while still maintaining an effective seal.

Springs or bellows inside the cartridge push the faces together with precisely calibrated force. The combination of spring pressure and fluid pressure from the pump keeps the faces in constant contact during operation.

The genius of this design is that it allows rotation while preventing leakage. The gap between the faces is so small that only an invisible amount of vapor can escape – essentially creating a leak-free seal.

Parts of Cartridge Mechanical Seal

The parts of cartridge seal work together as an integrated system. Each component has a specific role in preventing leaks and ensuring smooth operation.

- Primary Seal Faces (Rotating and Stationary) – These are the heart of the seal, made from ultra-hard materials like silicon carbide or tungsten carbide. The faces are lapped to extreme flatness, creating the primary barrier against leakage.

- Shaft Sleeve – A metal sleeve that slides over the pump shaft and carries all rotating components. It protects the shaft from wear and provides a mounting surface for the rotating seal face.

- Gland (Seal Housing/Flange) – The stationary housing that bolts to the pump and holds the stationary seal face. It includes ports for flush fluids or cooling when needed.

- Springs or Bellows (Mechanical Loading Device) – These provide the force that keeps seal faces together. The spring compression is preset at the factory for optimal performance.

- Secondary Seals – O-rings and gaskets that prevent leakage around the primary faces. They create static seals between components and allow slight movement for shaft vibration.

- Set Screws and Drive Pins – Hardware that locks the rotating assembly to the shaft and prevents the stationary face from spinning. These ensure proper opposition between the two faces.

- Setting Clips / Plates (Retaining Clips) – Temporary devices that hold everything in perfect alignment during shipping and installation. These must be removed before operation to activate the seal.

Types of Cartridge Seals

Cartridge seals come in three main configurations, each designed for specific applications and installation requirements.

Single Cartridge Seals

Single cartridge seals contain one set of sealing faces and represent the most common configuration. They handle general service applications where small amounts of vapor leakage are acceptable.

These seals work perfectly for water, oils, and non-hazardous chemicals. The process fluid itself provides lubrication for the seal faces during operation.

Most single cartridge seals feature balanced designs that reduce hydraulic loads on the faces. This allows them to handle pressures up to 25 bar while maintaining long service life.

Double Cartridge Seals

Double cartridge seals use two sets of seal faces for maximum safety and reliability. A clean barrier fluid circulates between the two seals, providing cooling and lubrication.

The inner seal contains the process fluid while the outer seal prevents barrier fluid from escaping. If one seal fails, the other continues protecting against leaks.

These designs are essential for toxic, flammable, or expensive fluids where any leakage is unacceptable. The barrier fluid system requires additional equipment but provides dramatically longer seal life in harsh conditions.

Split Cartridge Seals

Split cartridge seals come in two halves that clamp around the shaft. This revolutionary design allows seal replacement without dismantling the pump or connected piping.

Each half comes pre-assembled in its housing, maintaining the simplicity of cartridge installation. The halves join with precision-engineered surfaces that create an effective seal when bolted together.

Large mixers, vertical pumps, and equipment in tight spaces benefit most from split designs. While more expensive than one-piece cartridges, they can save days of downtime during replacement.

Advantages of Cartridge Mechanical Seal

- Simplified Installation – The entire unit slides onto the shaft and bolts in place without special measurements or adjustments. Installation time drops from hours to minutes compared to component seals.

- Reduced Installation Errors – Pre-assembled components eliminate common mistakes like incorrect spring compression or misaligned faces. The factory-set configuration ensures proper operation from startup.

- Shorter Downtime – Quick replacement means production resumes faster. A trained technician can swap a cartridge seal in a fraction of the time needed for component seal rebuilding.

- Enhanced Reliability and Seal Life – Proper face loading and alignment from the factory mean longer service intervals. Users report 2-3 times longer life compared to field-assembled seals.

- Safety and Environmental Protection – Reliable sealing prevents dangerous chemical releases and protects workers. The reduced maintenance time also minimizes exposure to hazardous areas.

- Maintenance Efficiency – Cartridge seals can be removed as complete units for workshop repair. Standardized designs mean one seal type can serve multiple pumps.

- Adaptability – Many cartridges work as drop-in replacements for packed pumps or older seals. The self-contained design fits various pump models with minimal modification.

Applications of Cartridge Mechanical Seal

- Oil and Gas Industry – Refineries and petrochemical plants use cartridge seals on pumps handling crude oil, gasoline, and volatile chemicals. Double cartridge seals with barrier fluids meet strict safety regulations for hazardous materials.

- Chemical Processing – Plants rely on specialized cartridge seals to contain corrosive acids, solvents, and toxic chemicals. Material selection allows seals to resist aggressive chemicals while protecting workers and environment.

- Water and Wastewater Management – Municipal water systems and treatment plants use cartridge seals in pumps moving millions of gallons daily. The seals prevent water loss and protect pump bearings from contamination.

- Power Generation – Power plants install cartridge seals on boiler feed pumps and cooling systems operating at high temperatures. These seals ensure continuous operation between scheduled maintenance periods.

- Pharmaceutical and Biotech – Sterile production requires sanitary cartridge seals made from FDA-compliant materials. Quick seal changes minimize downtime in critical batch processes.

- Food and Beverage – Dairy plants, breweries, and food processors need hygienic seals that prevent product contamination. Cartridge designs allow easy cleaning and meet strict food safety standards.

- Mining and Minerals – Heavy-duty cartridge seals handle abrasive slurries in mining operations. Hard seal faces and flush systems extend life in these punishing conditions.