Here’s a frustrating statistic: 60-70% of all centrifugal pump maintenance involves seal-related repairs. I’ve seen engineers spend thousands on premium seal faces while overlooking a $5 O-ring that caused the entire failure.

The culprit? Poor elastomer selection.

An elastomer in a mechanical seal is a flexible, rubber-like polymer that serves as the secondary sealing element. You’ll find elastomers in O-rings, bellows, and gaskets—the components that seal the gaps between the primary seal faces and their housings. While the seal faces get all the attention, these “silent partners” often determine whether your seal lasts months or years.

What Does an Elastomer Do in a Mechanical Seal?

How Does the Primary vs. Secondary Seal Work?

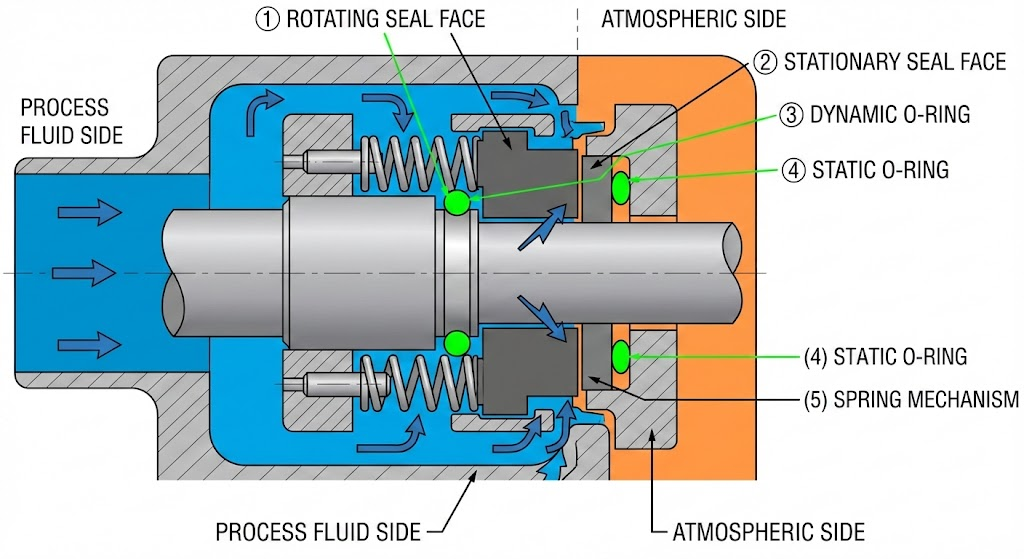

The primary seal in a mechanical seal is the dynamic interface between two lapped-flat faces—one rotating with the shaft, one stationary in the housing. This face-to-face contact prevents the bulk of fluid leakage.

Elastomers handle everything else.

They create secondary seals that close off all other potential leak paths. One O-ring seals the stationary face to the housing. Another seals the rotating face to the shaft sleeve. These secondary seals must accommodate axial movement, compensate for slight misalignment, and absorb vibration—all without losing their sealing force.

Think of it this way: the seal faces are the stars of the show, but elastomers are the stage crew. If they fail, the whole production falls apart.

What Are the Key Forms of Elastomers in Seals?

You’ll encounter elastomers in four main forms:

- O-rings: The most common secondary seal. These circular cross-section rings seat in grooves and compress between mating surfaces. Simple to install, widely available, and effective across a huge range of applications.

- Elastomeric bellows: Convoluted rubber tubes that flex to accommodate shaft movement. These eliminate the sliding friction of dynamic O-rings, making them popular where shaft hang-up is a concern.

- Cup seals and gaskets: Used in specific designs where O-rings won’t fit the geometry or where additional sealing force is needed.

- Encapsulated O-rings: A fluoropolymer jacket over an elastomer core. These combine the chemical resistance of PTFE with the resilience of rubber.

What Are the Common Types of Elastomers Used in Mechanical Seals?

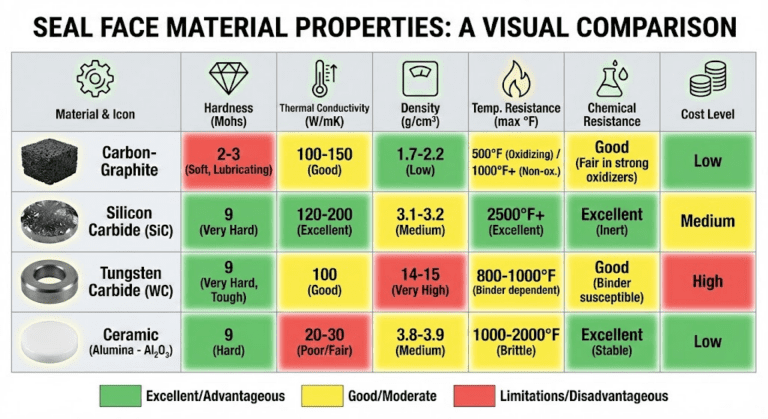

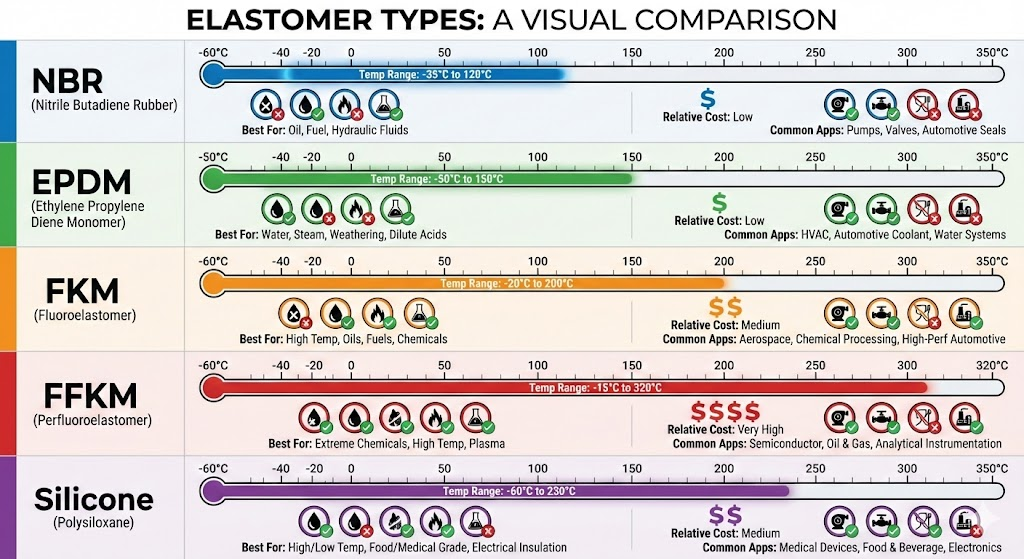

Five elastomer families dominate mechanical seal applications. Each has distinct strengths and weaknesses. The table below summarizes the key differences, followed by a deeper look at each material.

| Material | Temperature Range | Best For | Avoid |

|---|---|---|---|

| NBR (Nitrile) | -30°C to 110°C | Oils, fuels, hydrocarbons | Ozone, high temps |

| EPDM | -50°C to 150°C | Water, steam, mild chemicals | Oils, petroleum |

| FKM (Viton) | -20°C to 200°C | Chemicals, fuels, high temps | Ketones, acetones |

| FFKM | -20°C to 327°C | Aggressive chemicals, extreme temps | Budget applications |

| Silicone (VMQ) | -60°C to 230°C | Wide temp range, clean applications | Oils, solvents |

NBR (Nitrile/Buna-N)

Nitrile rubber is the default choice for a reason. It handles petroleum-based fluids exceptionally well and costs a fraction of premium elastomers.

I recommend NBR for most water-based and hydrocarbon applications where temperatures stay below 110°C. It offers good abrasion resistance and maintains its properties across a practical temperature range of -30°C to 110°C.

The catch? NBR deteriorates in ozone and sunlight. It also can’t handle polar solvents like ketones or chlorinated hydrocarbons. For outdoor installations or chemical plants, look elsewhere.

One detail worth knowing: the acrylonitrile content in NBR affects its properties. Higher acrylonitrile (38-50%) improves oil resistance but reduces low-temperature flexibility. Lower content (18-26%) works better in cold environments but swells more in oils.

EPDM

EPDM shines in water, steam, and mild chemical services. Its saturated backbone makes it essentially immune to ozone and UV degradation—a major advantage for outdoor equipment.

The operating range of -50°C to 150°C covers most water treatment and HVAC applications. EPDM also handles phosphate-ester hydraulic fluids, which destroy NBR.

Here’s the critical limitation: EPDM swells dramatically in petroleum products. I’ve seen EPDM O-rings double in volume after contact with mineral oil. Never use EPDM where any hydrocarbon exposure is possible—even trace contamination from greases or lubricants can cause problems.

Water treatment plants, cooling tower pumps, and steam systems are EPDM territory. Refineries and fuel handling are not.

FKM (Viton)

Fluoroelastomers like Viton offer the best all-around chemical resistance value in mechanical seals. They handle acids, fuels, oils, and many solvents that destroy other elastomers.

The temperature capability of -20°C to 200°C (and up to 250°C for short periods) makes FKM suitable for hot oil services, chemical reactors, and automotive applications.

FKM costs roughly eight times more than EPDM. That premium buys you resistance to over 90% of industrial chemicals and excellent compression set resistance at elevated temperatures.

Two things FKM can’t handle: ketones and low-molecular-weight esters. Acetone, MEK, and ethyl acetate will swell FKM rapidly. For these fluids, you’ll need FFKM or a non-elastomeric alternative.

Chemical processing, pharmaceutical manufacturing, and oil and gas installations typically specify FKM as the standard elastomer.

FFKM (Perfluoroelastomer)

When nothing else survives, FFKM steps in. Perfluoroelastomers like Kalrez and Chemraz offer chemical resistance approaching PTFE while maintaining the elasticity of rubber.

FFKM handles temperatures from -20°C to 327°C and resists nearly every chemical short of molten alkali metals and certain fluorinated compounds.

The price reflects the performance: FFKM seals cost 50-100 times more than NBR equivalents. You won’t specify FFKM casually.

I recommend FFKM for aggressive chemical services, semiconductor manufacturing, and pharmaceutical applications where contamination can’t be tolerated. The cost is justified when a single seal failure causes millions in downtime or product loss.

Silicone (VMQ)

Silicone offers the widest practical temperature range of any common elastomer: -60°C to 230°C. It maintains flexibility in cryogenic conditions where other elastomers turn brittle.

The ozone and UV resistance rivals EPDM. FDA and food-grade formulations make silicone the go-to choice for food processing and pharmaceutical applications.

Silicone’s weakness is mechanical. It tears easily, wears quickly in dynamic applications, and swells in petroleum products. The compression set resistance is mediocre at best.

Use silicone for static or low-motion applications in clean environments. Dairy equipment, medical devices, and laboratory instruments are ideal applications. High-speed pumps and abrasive services are not.

How Do You Select the Right Elastomer for Your Application?

What Factors Determine Elastomer Selection?

Choosing the right elastomer comes down to six questions:

- What fluid will contact the seal? Chemical compatibility is non-negotiable. An incompatible elastomer will fail within weeks—sometimes days.

- What’s the temperature range? Consider both continuous operating temperature and peak excursions. A pump running at 80°C might see 150°C during steam cleaning.

- What pressure will the seal experience? High pressures require elastomers with better extrusion resistance. Harder durometers (80-90 Shore A) help prevent nibbling.

- Is the application static or dynamic? Dynamic seals need lower compression set and better wear resistance than static ones.

- What regulations apply? FDA, NSF, USP Class VI, and other certifications limit your material choices in food, water, and medical applications.

- What’s your budget? FFKM might be ideal, but NBR might be good enough. Match the material to the actual service requirements.

How Do You Check Chemical Compatibility?

Never guess on chemical compatibility. I’ve watched engineers specify Viton for a “general chemical service” only to discover the process included acetone washes that destroyed the seals monthly.

Start with compatibility charts from seal manufacturers like Parker, Trelleborg, or Freudenberg. These charts rate elastomer performance from A (excellent) to D (not recommended) for thousands of chemicals.

Check compatibility for every fluid that might contact the seal—not just the primary process fluid. Cleaning agents, sterilants, and trace contaminants all matter.

Temperature changes the equation dramatically. Chemical reaction rates roughly double for every 10°C rise. An elastomer that handles a chemical at 25°C might fail at 80°C. Always check compatibility at your actual operating temperature.

When the fluid isn’t listed or you’re uncertain, test before installing. Immerse a sample O-ring in the fluid at operating temperature for 72 hours, then check for swelling, hardening, or weight change. A volume change over 10% signals incompatibility.

What Physical Properties Should You Evaluate?

Beyond chemical compatibility, four physical properties determine seal performance:

| Property | What It Means | Typical Values |

|---|---|---|

| Compression Set | How well the elastomer recovers after being squeezed | Lower is better; <20% is excellent |

| Durometer Hardness | Resistance to indentation | 70-90 Shore A for most seals |

| Tensile Strength | Maximum stress before breaking | 7-20 MPa typical |

| Elongation | How far it stretches before breaking | 100-300% typical |

Compression set matters most for long-term sealing. An O-ring with 50% compression set has lost half its ability to spring back. Industry guidance considers 80-85% compression set as end-of-life.

Durometer affects both sealing and extrusion resistance. Softer elastomers (60-70 Shore A) seal irregular surfaces better. Harder elastomers (80-90 Shore A) resist extrusion at higher pressures. Most mechanical seal O-rings fall in the 70-85 Shore A range.

Conclusion

Elastomers are the secondary sealing elements that prevent leakage between the primary seal faces and their housings. They come in five main families—NBR, EPDM, FKM, FFKM, and silicone—each suited to specific temperature ranges and chemical environments.

Getting elastomer selection right requires matching the material to your actual operating conditions. Check chemical compatibility charts for every fluid that might contact the seal. Verify temperature ratings against both continuous operation and peak excursions. Consider the physical demands: static or dynamic, low pressure or high.

When elastomers reach their limits—cryogenic temperatures, aggressive chemicals, extreme heat—alternatives like PTFE, metal bellows, and graphite-filled materials fill the gap.

The $5 O-ring you overlook today might cause the $50,000 repair you regret tomorrow. Take elastomer selection as seriously as seal face selection, and your mechanical seals will reward you with years of reliable service.