The fundamental difference between these two piping plans comes down to pressure direction. A flush line (API Plan 11) increases seal chamber pressure to 100% of discharge pressure. A suckback line (API Plan 13) reduces it to equal suction pressure. This pressure difference fundamentally changes seal behavior and determines which applications each plan suits.

This comparison will give you a clear decision framework for selecting the right plan, complete with specifications, troubleshooting guidance, and a straightforward selection matrix.

What Is the Functional Difference Between a Flush Line and a Suckback Line?

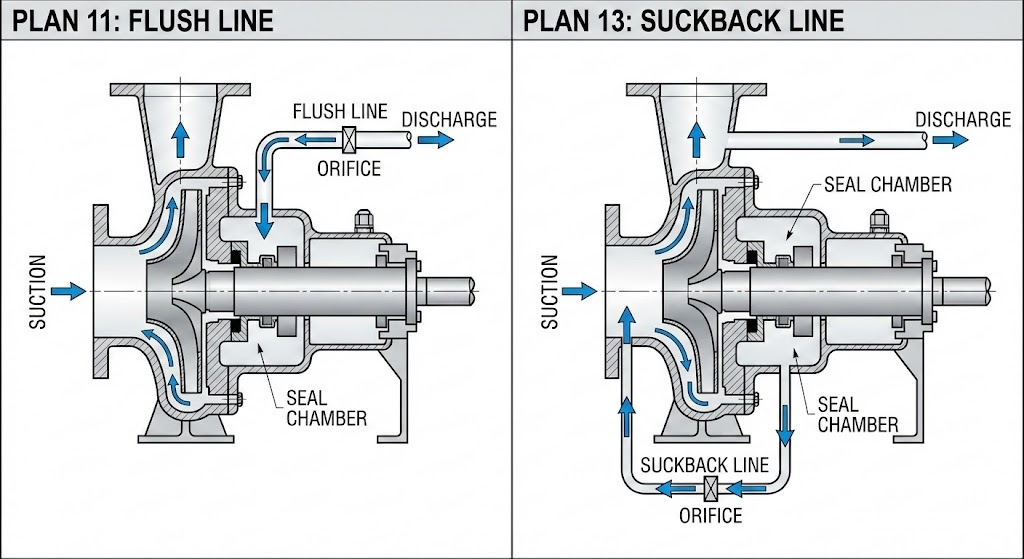

The core difference is flow direction and its effect on stuffing box pressure in a mechanical seal. A flush line pushes fluid into the seal chamber from discharge. A suckback line pulls fluid out of the seal chamber toward suction.

Flush Line (API Plan 11): Flow from Discharge to Seal Chamber

A flush line routes high-pressure fluid from the pump discharge through an orifice and into the seal chamber. The flow direction is: Discharge to Orifice to Seal chamber to Back into pump.

This arrangement increases stuffing box pressure to 100% of discharge pressure. The primary purposes include flushing debris away from seal faces, cooling the seal, and maintaining adequate vapor pressure margin. API Plan 11 remains the default choice for most applications because it accomplishes multiple objectives with simple piping.

The orifice controls flow rate by creating a pressure drop between discharge and the seal chamber. For most horizontal pump applications, I recommend Plan 11 as your starting point – it covers 50-75% of all seal applications for good reason.

Suckback Line (API Plan 13): Flow from Seal Chamber to Suction

A suckback line works in reverse. Fluid flows from the seal chamber through an orifice back to pump suction. The flow direction is: Seal chamber to Orifice to Pump suction.

This arrangement reduces stuffing box pressure to equal suction pressure. The primary purposes include relieving excessive seal chamber pressure, providing self-venting capability, and removing vapor from vertical pump configurations. API Plan 13 is sometimes called a “reverse flush” because of this opposite flow direction.

The orifice in Plan 13 creates backpressure rather than controlling inlet flow. This distinction matters for sizing calculations.

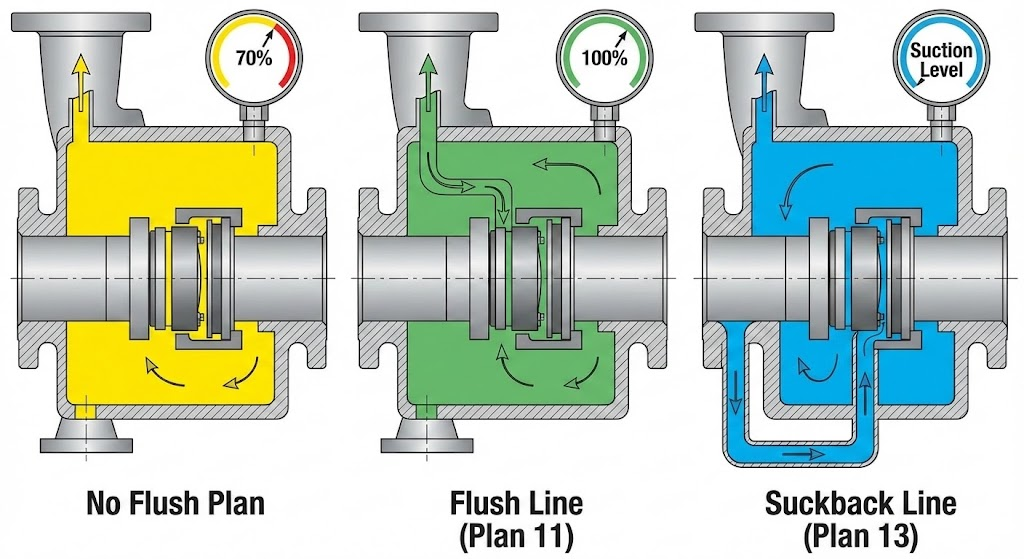

The Pressure Rule: 70% / 100% / Suction

Understanding the pressure effects provides a clear mental model for selection decisions. The table below shows how each configuration affects seal chamber pressure.

| Configuration | Stuffing Box Pressure |

|---|---|

| No flush plan | Approximately 70% of discharge pressure |

| With flush line (Plan 11) | 100% of discharge pressure |

| With suckback line (Plan 13) | Equal to suction pressure |

This 70/100/suction rule provides the foundation for understanding when each plan applies. If you need higher pressure at the seal, use a flush line. If you need lower pressure, use a suckback line.

When Should You Use a Flush Line vs a Suckback Line?

Selection depends primarily on pump orientation and pressure requirements. Horizontal pumps generally favor Plan 11. Vertical pumps typically require Plan 13 or Plan 14.

Choose Flush Line (Plan 11) When:

Plan 11 should be your default consideration for the following situations:

- Horizontal pump applications with standard configurations

- Clean, non-polymerizing fluids that won’t clog the orifice

- Applications requiring increased seal chamber pressure

- Sufficient differential pressure exists between discharge and seal chamber

- Hydrocarbon service under 150 degrees Celsius with satisfactory vapor pressure margin

The key advantage of Plan 11 is more efficient heat removal compared to Plan 13. The higher pressure also increases vapor pressure margin, which prevents the pumped fluid from flashing at the seal faces.

Choose Suckback Line (Plan 13) When:

Plan 13 becomes the better choice in specific circumstances:

- Vertical pumps without a bleed bush installed below the seal chamber

- High-head horizontal pumps where Plan 11 cannot provide adequate flow

- Applications requiring pressure reduction at the seal

- High differential pressure situations that would require multiple orifices with Plan 11

Vertical pumps should use Plan 13 or Plan 14. Plan 11 alone cannot provide adequate venting in vertical configurations because vapor tends to collect at the top of the seal chamber with no escape path.

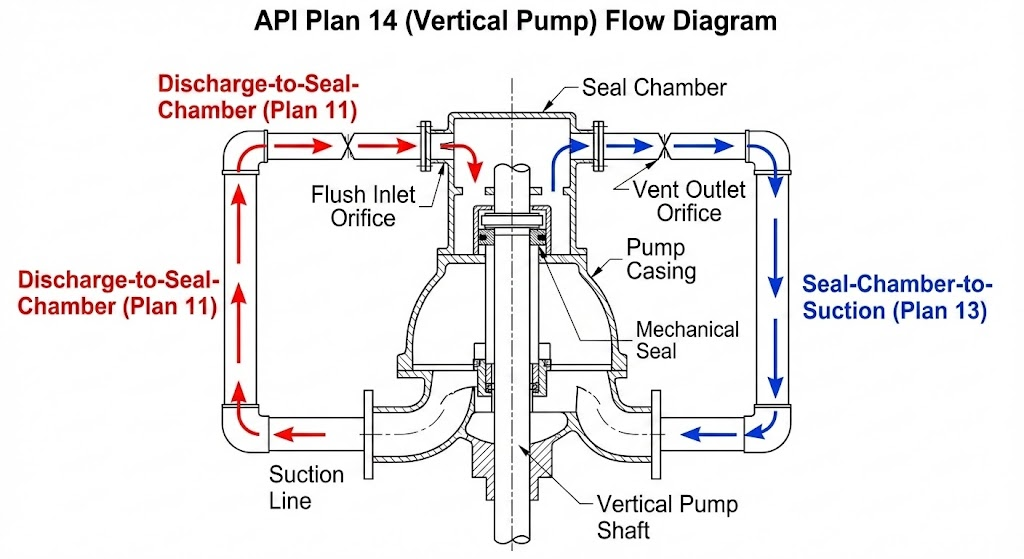

What About Plan 14? The Combination Approach

Plan 14 combines Plan 11 and Plan 13 simultaneously. Flow recirculates from the pump discharge into the seal chamber while also flowing from the seal chamber to the pump suction.

This combination is most commonly used on vertical pumps. Plan 14 provides adequate flush flow, continuous venting capability, and improved vapor pressure margin – addressing limitations that either plan has individually.

Consider Plan 14 for viscous products where the throat bushing restricts flow, light hydrocarbons subject to flashing, or any vertical pump application where single plans prove inadequate.

What Are the Advantages and Disadvantages of Each Approach?

Each plan involves trade-offs. The comparison table below summarizes the key differences for decision-making.

Comparison Table: Flush Line vs Suckback Line

| Factor | Flush Line (Plan 11) | Suckback Line (Plan 13) |

|---|---|---|

| Heat removal | More efficient | Less efficient |

| Self-venting | Yes (horizontal pumps) | Yes (better for vertical pumps) |

| Pressure effect | Increases chamber pressure | Reduces chamber pressure |

| Best for | Horizontal pumps, general duty | Vertical pumps, high head |

| Flow control | Orifice controls flow | Orifice creates backpressure |

| Complexity | Simple, most common | Standard for specific applications |

| Market usage | 50-75% of all seal applications | Specialized applications |

Plan 11 dominates the market because it handles the majority of common pumping scenarios effectively. However, forcing Plan 11 into vertical pump applications is a mistake I see frequently.

Limitations to Consider

Flush line (Plan 11) limitations:

- Avoid with media containing solids, abrasives, or polymerizing substances

- Not recommended when differential pressure between discharge and seal chamber is too low

- Orifice can clog with contaminated fluids

- No vapor venting capability in vertical pump configurations

Suckback line (Plan 13) limitations:

- Less efficient cooling requires higher flow rates to compensate

- Complex flow control may be needed for high differential pressures

- Not suitable when seal chamber pressure is very close to suction pressure

- Low flow results if differential pressure is minimal

What Flow Rates and Temperature Limits Apply?

Proper sizing prevents both insufficient cooling and excessive erosion. The guidelines below apply to both flush and suckback configurations.

Flow Rate Guidelines

The industry rule of thumb is 1 GPM per inch of seal size. For a 2-inch seal, plan for approximately 2 GPM of flush flow.

Flashing services require double the standard rate – 2 GPM per inch of seal size. The additional flow compensates for heat absorbed during vaporization.

All orifices should have a minimum bore of 3 mm (1/8 inch). Plan 13 typically uses a larger orifice of 6 mm (1/4 inch) to effectively vent vapors.

For detailed calculations, refer to guidance on how to calculate flush flow rate for mechanical seals.

Temperature Rise Limits

Seal face temperature must stay within acceptable limits to prevent premature wear. The maximum allowable temperature rise varies by fluid type.

| Fluid Type | Maximum Temperature Rise |

|---|---|

| Water | 15 degrees Fahrenheit |

| Light hydrocarbons | 5 degrees Fahrenheit |

| Lube oils | 30 degrees Fahrenheit |

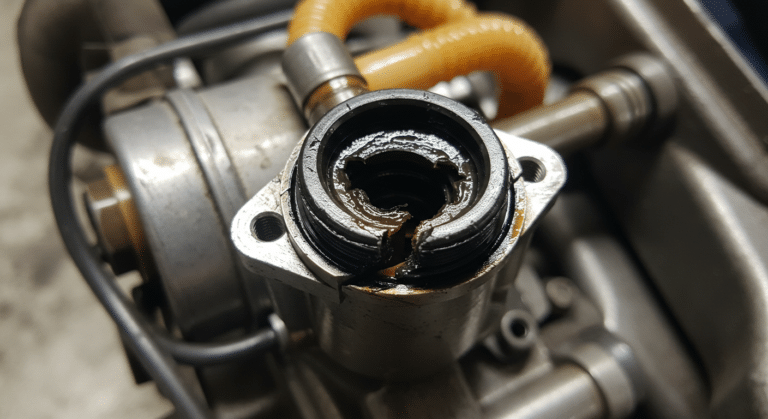

These limits explain why hydrocarbon services demand particular attention. A mechanical seal can experience thermal shock and shatter within 30 seconds of dry running – making adequate flush flow critical.

The vapor pressure margin should be approximately 50 psi above vapor pressure to prevent flashing at the seal faces. If your flush plan cannot maintain this margin, consider upgrading to Plan 23 with a cooler or Plan 32 with an external flush source.