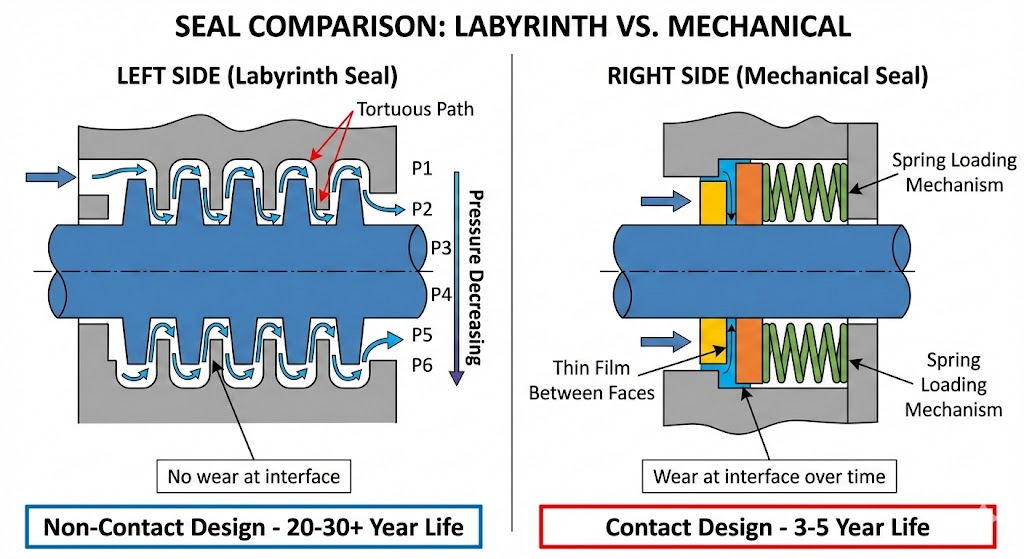

When you’re selecting a seal for rotating equipment, you face a critical choice: labyrinth or mechanical.

Both seals do the same job—prevent fluid from leaking along a rotating shaft. But they take fundamentally different approaches. One prioritizes durability and cleanliness. The other prioritizes stopping leaks cold.

How Labyrinth Seals Work

A labyrinth seal doesn’t touch anything. That’s its superpower and its defining characteristic.

Instead of relying on physical contact, a labyrinth seal creates a maze-like path that forces fluid to take the long way around. Imagine water trying to flow through a series of progressively tighter passages with sharp turns at every corner. That’s how a labyrinth seal stops leakage.

The Maze Design: Grooves That Block Flow

Labyrinth seals feature a series of interlocking grooves or “teeth” machined either on the rotating shaft, the stationary housing, or both. As the shaft rotates, these teeth move through the corresponding grooves, creating a constantly shifting barrier.

The fluid must navigate through multiple chambers and narrow passages. It’s not a straight path. The groove geometry forces the fluid to make sharp 90-degree direction changes. Each turn slows the fluid down and changes its momentum.

Pressure Drops: The Real Secret

Here’s what stops the leak: each passage throttles the flow. As fluid accelerates through a narrow opening, it gains speed. Then it hits the next chamber, and all that kinetic energy gets dissipated as turbulence and friction against the walls. The pressure drops.

This happens repeatedly. Fluid enters a chamber, accelerates through an opening, loses that energy, enters another chamber, and does it all again. By the time the fluid has made it through 4-6 chambers, the pressure difference is so reduced that leakage essentially stops. This is called throttling, and it’s elegantly simple.

Labyrinth seals typically allow just 1-3% leakage, depending on design and conditions. That’s controlled, predictable leakage rather than a gushing failure.

Centrifugal Force: High-Speed Advantage

At higher speeds, something else kicks in: centrifugal force.

When a labyrinth seal rotates, the fluid gets pushed outward toward the walls by centrifugal effects. If the seal is designed right, any fluid that does escape into a labyrinth chamber gets trapped in a vortex-like motion. This spinning motion actually repels other fluid, preventing further escape.

This is why labyrinth seals perform better the faster they spin. A labyrinth seal running at 10,000 RPM seals better than the same seal running at 3,000 RPM.

How Mechanical Seals Work

A mechanical seal takes the opposite approach. It works by forcing two surfaces together under pressure so tightly that nothing can get through.

Two Faces Under Pressure: The Sealing Barrier

A mechanical seal has two primary components: a rotating seal face and a stationary seal face. These faces are manufactured to extremely high precision—flat to within microinches. One face moves with the shaft. The other stays fixed in the pump housing.

Springs or bellows push these faces together with controlled force. The contact between them is what creates the seal. Think of two perfectly flat glass plates pressed together. Water can’t flow between them because the fit is too precise.

The Critical Fluid Film

Here’s the magic part: you don’t actually want the faces in direct metal-to-metal contact.

Between the seal faces exists an ultra-thin lubricating film, usually just a few micrometers thick. This film is typically made from the process fluid itself—the liquid you’re trying to seal. The film accomplishes three things simultaneously: it reduces friction, prevents face wear, and maintains the seal.

The seal works because the fluid film keeps the faces separated by just enough distance to prevent leakage. If the film breaks down—due to contamination, heat, or poor operating conditions—the faces can touch, damage each other, and the seal fails.

Springs and Loading: Maintaining Pressure

Springs or bellows keep consistent pressure on the seal faces as they wear. Over time, the seal faces gradually wear down due to friction and micro-contact. The springs automatically compensate by pushing harder to maintain the fluid film.

This is why a mechanical seal can maintain performance for 3-5 years before needing replacement. The spring system keeps the seal faces in contact even as they wear.

Secondary Seals and Support

Beyond the primary seal faces, mechanical seals include secondary seals: O-rings, gaskets, and elastomeric components that prevent leakage from other parts of the assembly. These secondary seals also have temperature and material limitations, which can restrict where mechanical seals can operate.

Key Differences at a Glance

| Aspect | Labyrinth Seal | Mechanical Seal |

|---|---|---|

| Core Design | Non-contacting (no touch) | Contacting (face-to-face) |

| Leakage Rate | 1-3% controlled | <0.1% (near-zero) |

| Heat Generation | Minimal | Moderate (face friction) |

| Wear | Virtually none | Gradual face wear |

| Service Life | 10-30+ years | 3-5 years typical |

| Maintenance | Minimal (periodic cleaning) | Regular (face replacement, O-ring changes) |

| Cost | Lower upfront | Higher upfront |

| Operating Speed Range | Improves with higher speeds | Consistent across speeds |

| Pressure Handling | Limited | High pressure capable |

| Temperature | High (no elastomers) | Moderate (elastomer limits) |

When to Choose a Labyrinth Seal

High-Speed Rotating Equipment

If your equipment spins fast—gas turbines, centrifugal compressors, high-speed pumps above 3,000 RPM—a labyrinth seal is often the better choice. The centrifugal effects enhance sealing as speed increases.

Examples include gas turbine engines in power plants, natural gas compressors, turbochargers, and superchargers.

Contaminated or Dusty Environments

When your equipment operates where airborne dust, splashing liquids, or heavy washdown occurs, the labyrinth path’s particle-blocking ability becomes valuable. The seal actively excludes contaminants.

Machine tools with coolant spray, mining equipment in dusty conditions, outdoor construction equipment, and food processing with washdown all benefit from labyrinth seals.

Bearing Protection

Labyrinth seals are specifically designed to protect sensitive bearing surfaces. The particle-blocking capability extends bearing life in dirty environments and prevents premature bearing failure from contamination.

Rolling element bearings in machine tools, motors, and construction equipment commonly use labyrinth seals as bearing shields.

Long-Service-Life Requirements

When your application demands minimal maintenance and replacement—remote installations, equipment where replacement is costly or disruptive, systems designed for 20+ year operational life—a labyrinth seal’s 20-30 year lifespan is a major advantage.

Dry-Running or Low-Lubrication Applications

Labyrinth seals work effectively without relying on the process fluid for lubrication. If your sealed medium doesn’t provide adequate lubrication, a labyrinth seal is the better choice.

When to Choose a Mechanical Seal

Zero or Near-Zero Leakage Requirements

If your application can’t tolerate any fluid loss—hazardous chemicals, expensive fluids, environmental regulations, sterility requirements—a mechanical seal is mandatory.

Chemical plants handling toxic materials, pharmaceutical operations, oil refineries, and food processing facilities all use mechanical seals to meet regulatory requirements.

High-Pressure Applications

Mechanical seals handle pressures that labyrinth seals cannot. High-pressure injection systems, pressurized reactors, and hydrocarbon processing equipment all require mechanical seals.

Labyrinth seals struggle with significant pressure differentials across the seal. Mechanical seals handle them as a matter of course.

Variable or Low-Speed Equipment

Mechanical seals maintain consistent performance regardless of speed. Mixers and agitators operating at variable speeds, slow-speed high-torque equipment, and applications with frequent stop-start cycles all perform better with mechanical seals.

A labyrinth seal’s performance degrades at low speeds; a mechanical seal’s doesn’t.

Extreme Temperature Conditions

For sustained operation at very high (above 150°C) or very low (below -50°C) temperatures, mechanical seals with appropriate material selections outperform labyrinth seals.

Hot oil circulation systems, cryogenic equipment, and thermal processing all require mechanical seals.

Chemical or Slurry Pumping

When you’re pumping abrasive slurries, corrosive chemicals, or suspended particles, mechanical seals with appropriate face materials handle it better. Slurry pumping in mining, chemical transfer operations, and abrasive particle handling all use mechanical seals.

Regulatory or Compliance Requirements

Many industries mandate mechanical seals by standard or regulation. API 682 in the oil and gas industry, FDA regulations in pharmaceutical operations, and EPA requirements in chemical processing all essentially require mechanical seals.

Check your industry standards before choosing a seal type.

Selection Decision Guide

Ask yourself these questions:

What’s your primary concern?

- If durability and low maintenance: labyrinth seal

- If leakage prevention: mechanical seal

How fast does your equipment run?

- Above 3,000 RPM: labyrinth seal

- Variable speed or below 1,000 RPM: mechanical seal

What’s your leakage tolerance?

- 1-3% acceptable: labyrinth seal

- Must be <0.5%: mechanical seal

What’s your environment?

- Dusty or contaminated: labyrinth seal

- Clean controlled environment: mechanical seal

What pressure differential exists?

- Minimal pressure difference: labyrinth seal

- Significant pressure differential: mechanical seal

What’s your budget?

- Lower cost priority: labyrinth seal

- Performance priority: mechanical seal

How often can you maintain equipment?

- Minimal maintenance acceptable: labyrinth seal

- Regular maintenance acceptable: mechanical seal

What’s your service life expectation?

- 10-30+ years: labyrinth seal

- 3-5 years acceptable: mechanical seal

Conclusion

Labyrinth seals and mechanical seals serve the same fundamental purpose but take radically different philosophical approaches. Labyrinth seals prioritize durability, low maintenance, and contamination control. They accept modest leakage to avoid wear and achieve 20-30 year service lives. Mechanical seals prioritize stopping leaks and handling extreme conditions. They trade maintenance and shorter service life for near-zero leakage and pressure capability.

Your choice depends on your specific situation. High-speed, high-contamination environments with acceptable leakage point toward labyrinth seals. Zero-leakage requirements, high pressure, or extreme operating conditions point toward mechanical seals.