What Is Mechanical Seals for Compressors

Wet Seals

Wet seals, or liquid seals, use a thin liquid film, typically oil, to form a barrier between the rotating shaft and the stationary housing, preventing gas leakage and maintaining pressure.

Wet seals minimize equipment wear and tear. The liquid film reduces friction between moving parts, extending the compressor’s lifespan. The liquid’s cooling properties also dissipate heat generated during operation, protecting the compressor from damage.

Wet seals handle high-pressure environments effectively. They suit applications where compressors operate under extreme conditions, such as the oil and gas industry. Maintenance is straightforward, as the liquid can be easily monitored and replaced when necessary.

Dry Gas Seals

Dry gas seals enhance compressor efficiency and reliability by eliminating the need for a liquid barrier, thus avoiding risks associated with leakage and contamination. They use a thin film of gas, typically nitrogen or air, to form a seal between rotating and stationary components.

Choosing dry gas seals reduces maintenance costs and increases operational uptime. These seals can handle high pressures and speeds, making them suitable for various industrial applications. They facilitate quick inspections and replacements, minimizing downtime.

Operating without external lubrication, dry gas seals lower the risk of oil contamination in compressor systems.

Seal Arrangements

When selecting mechanical seals for compressors, you need to consider different seal arrangements like single seals, tandem seals, and double seals.

Single Seals

Single seals typically include a rotating seal face and a stationary seal face. These components collaborate to prevent leakage by forming a tight seal around the compressor shaft. The primary benefit is the reduced initial investment compared to more intricate sealing systems.

Consider the operating conditions when assessing single seals. They excel in environments with clean, non-abrasive fluids where minor leakage is tolerable. However, they are not ideal for hazardous or highly pressurized applications where even small leaks are problematic.

Tandem Seals

Tandem seals consist of two seals arranged in series, offering an extra layer of protection. If the first seal fails, the second one acts as a backup, ensuring continued operation and preventing leakage.

Tandem seals prove especially useful in applications involving hazardous, toxic, or expensive process fluids. This arrangement minimizes the risk of environmental contamination and product loss. They also handle varying pressure levels effectively, with the primary seal facing the process pressure and the secondary seal managing the buffer or barrier fluid pressure.

Tandem seals extend the lifespan of equipment. The secondary seal reduces the load and wear on the primary seal, avoiding frequent maintenance and unexpected downtime. High-speed compressors or those operating under fluctuating conditions benefit significantly from the reliability of tandem seals.

Double Seals

Double seals, or dual seals, enhance security and efficiency in mechanical systems by incorporating two sets of sealing faces, creating an additional barrier against leakage. These seals are particularly advantageous when handling hazardous or toxic fluids, ensuring the compressor operates safely and reliably.

Double seals come in two main configurations: back-to-back and face-to-face. In the back-to-back arrangement, the seals face away from each other, an ideal setup for high-pressure environments. This configuration manages fluctuating pressures effectively by allowing pressure balancing between the seals. Conversely, the face-to-face arrangement positions the seal faces towards each other, suitable for lower pressure applications. This setup often employs a barrier fluid for lubrication and cooling.

One significant advantage of double seals is redundancy. If one seal fails, the second continues to function, reducing downtime and preventing leaks.

Factors in Selecting Compressor Seals

Compressor Type

Choosing the right mechanical seals for compressors hinges directly on the type of compressor you’re dealing with: rotary vane, scroll, centrifugal, reciprocating, or screw.

For rotary vane compressors, select seals that handle continuous contact with rotating vanes. These compressors often require seals with excellent wear resistance and durability.

Scroll compressors operate with a spiral motion, demanding seals that accommodate both radial and axial movements. Flexibility and low leakage are essential.

In centrifugal compressors, seals must endure high-speed rotations and radial forces. Non-contacting seals often work best to maintain stability and integrity while avoiding friction.

Reciprocating compressors use a piston moving back and forth, placing unique demands on seals. These seals must withstand high pressure and frequent motion, ensuring a tight seal in both directions.

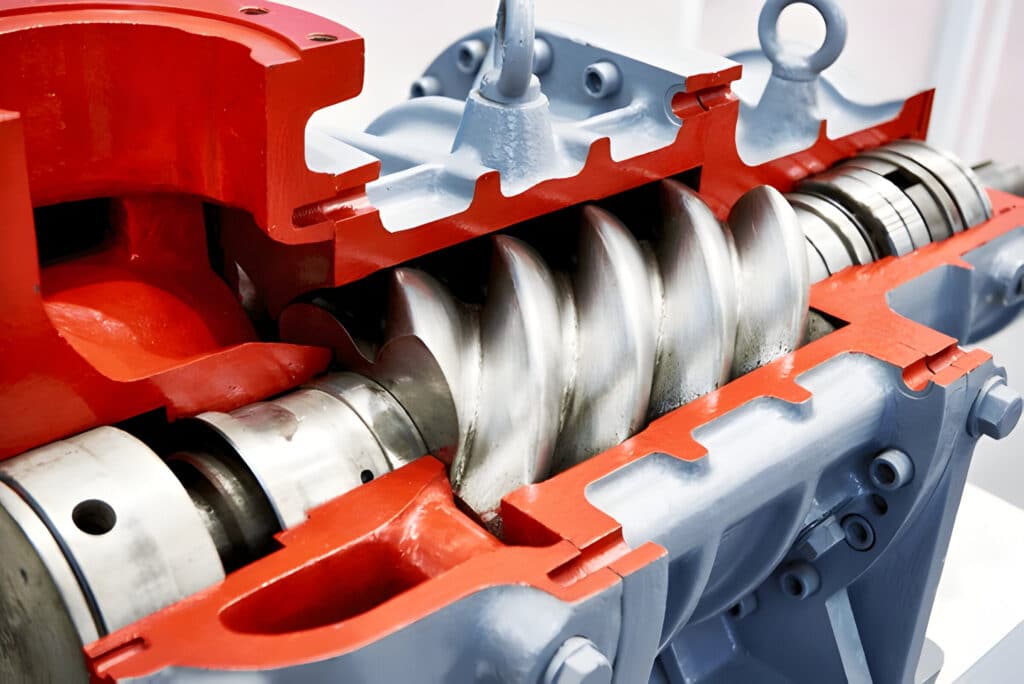

Screw compressors use meshing screws to compress gas, requiring seals that handle axial loads and prevent leakage. Durability and resistance to deformation are key.

Operating Conditions

The operating conditions of your compressor—pressure, temperature, and speed—determine the appropriate mechanical seals.

High-pressure environments require seals made from robust materials to resist deformation and leakage. Seals with higher pressure ratings prevent failures that lead to costly downtime or damage. Conversely, low-pressure systems may allow for more flexible and cost-effective seals.

Extreme temperatures can cause seal materials to expand, contract, or degrade. Select seals designed to handle the thermal range of your operation to maintain integrity. For high-temperature applications, use seals made from materials like PTFE or graphite.

Speed impacts seal wear and tear. Faster-operating compressors generate more friction and heat, accelerating seal degradation. Choose seals that endure high rotational speeds without compromising performance. Verify the seal’s speed rating to match your compressor’s operational speed.

Process Fluid Properties

If the process fluid contains abrasive particles or reactive chemicals, select seals made from materials that resist wear and corrosion.

High-viscosity fluids require seals that can manage thicker liquids without performance loss. Low-viscosity fluids, on the other hand, demand tighter seal tolerances to avoid leakage.

For toxic process fluids, choose seals that ensure zero leakage to protect equipment and personnel. Materials like PTFE are preferable for their chemical inertness and resistance to degradation.

For flammable fluids, use seals that minimize friction and heat generation to prevent ignition. Seals with fire-resistant properties or those designed to operate at lower temperatures enhance safety.

Environmental and Safety Requirements

Compliance with environmental laws and safety standards is mandatory. Non-compliance can result in fines and damage to the company’s reputation. Ensure the mechanical seals are certified and meet relevant industry standards.

Ease of maintenance and replacement is also important. Difficult-to-service seals can lead to longer downtimes, increasing the risk of leaks or exposure to hazardous materials.

Seal Material Compatibility

Different fluids, whether gases, liquids, or a mix, can interact differently with seal materials. For example, acidic or alkaline fluids may corrode certain metals, while high-viscosity fluids could wear down softer materials quickly.

Compatibility with lubricants and other chemicals used in the compressor system is another important factor. Certain seals may swell, harden, or crack when exposed to specific lubricants. To avoid premature failure and maintenance issues, always check the manufacturer’s compatibility charts and consult experts if unsure.

FAQs

What Are the Common Signs of Mechanical Seal Failure in Compressors?

Mechanical seal failure in compressors is indicated by leaks, unusual noises, and increased vibration. Excessive wear on seal components and frequent maintenance issues also signal the need to check and potentially replace the seals.

Can Mechanical Seals Be Retrofitted to Existing Compressors?

Yes, mechanical seals can be retrofitted to existing compressors. Ensure compatibility with the compressor’s design and operating conditions for optimal performance.