What Is a Pool Pump Shaft Seal

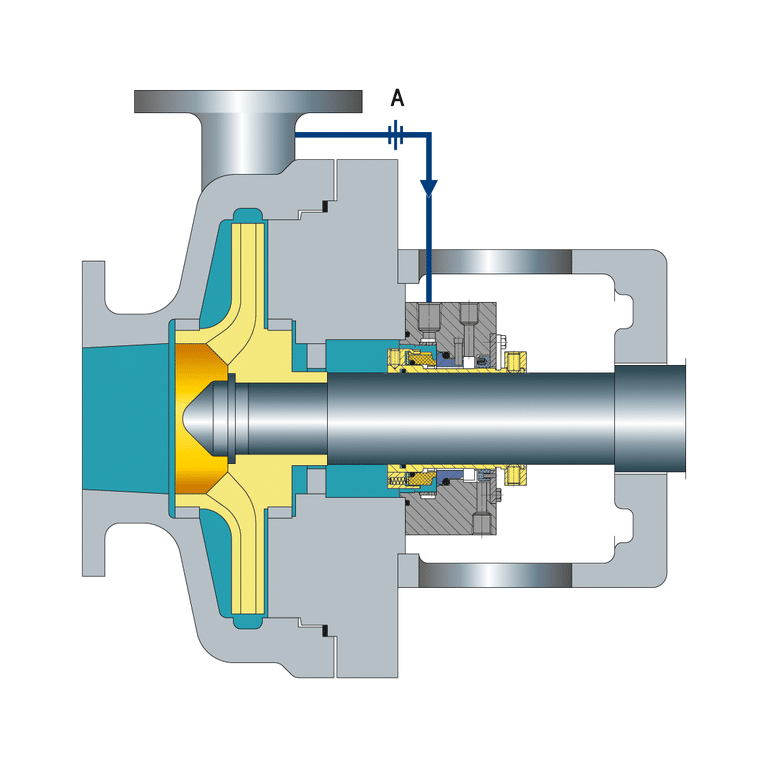

A pool pump shaft seal is a mechanical seal that prevents water from leaking along the pump shaft and into the motor. The seal is located between the pump housing and the motor, and it consists of two main parts: a rotating part (the spring seal) and a stationary part (the ceramic seat).

The seal materials are typically made of durable substances like silicon carbide, Viton rubber, or ceramic to withstand the constant pressure and corrosiveness of pool water, especially in saltwater pools.

How Does a Pool Pump Shaft Seal Work

The pool pump shaft seal works by creating a tight fit between the rotating and stationary parts of the seal. The spring half of the seal mates with the ceramic seat, forming a polished surface that prevents water from passing through.

As the impeller rotates, it creates a centrifugal force that pushes water away from the seal, further reducing the chance of leakage. The seal also includes rubber components that help to maintain a tight fit and prevent air leaks, which can cause a loss of pump prime.

Advantages of Pool Pump Shaft Seal

- Leak Prevention: The primary function of a shaft seal is to prevent water leakage, which can damage the pump motor and lead to costly repairs.

- Improved Efficiency: A properly functioning seal maintains the pump’s prime, ensuring optimal water flow and filtration.

- Extended Pump Life: By preventing leaks and maintaining efficiency, a good shaft seal can help extend the life of your pool pump.

- Compatibility: Shaft seals are available for a wide range of pool pumps, including major brands like Hayward Super Pump, Hayward Max-Flo pump, and Dyna-Max pumps.

When to Use Pool Pump Shaft Seal

Pool pump shaft seals are essential for all types of pool pumps, including inground pool pumps, above-ground pumps, and spa pumps. They are particularly critical in the following situations:

- Saltwater Pools: Salt chlorine generators are a popular choice for pool sanitation, but the corrosiveness of saltwater can lead to premature seal failure. Using a high-quality, salt-resistant shaft seal is crucial in these environments.

- High-Pressure Applications: Pumps that operate under high pressure, such as those used for water features or pool cleaners, require durable shaft seals to prevent leaks and maintain performance.

- Continuous Operation: For pools and spas that require constant filtration, a reliable shaft seal ensures uninterrupted operation and prevents costly downtime.

Why Do Pool Pump Shaft Seals Fail

- Chemical degradation: Exposure to harsh chemicals, such as those used in saltwater pools or salt chlorine generators, can cause premature failure of the seal materials. The corrosiveness of salt water can lead to complete seal failure if not addressed promptly.

- Running dry: If the water levels in the pump basket fall below the required level, the pump may run dry, causing the seal to overheat and fail. This can also happen if there is an air leak in the system, leading to a loss of pump prime.

- Water hammer effect: Sudden changes in water pressure within the pump housing can create a “water hammer” effect, putting excessive stress on the mechanical shaft seal and causing it to fail. This can be caused by abrupt starts or stops of the pump motor.

- Bad installation: Improper seal installation, such as using the wrong lubricant or damaging the polished surface of the ceramic seat during installation, can lead to premature failure.

- Warped or defective seal plate: A damaged or warped seal plate can prevent the spring half of the seal from mating properly with the ceramic seat, resulting in leakage and eventual failure. Always inspect the seal plate for damage before installing a new pool pump shaft seal.

How Do I Know If My Shaft Seal Is Bad

- Water Leakage: If you notice water leaking from the pump housing or around the motor, it may indicate a damaged shaft seal.

- Reduced Water Flow: A failing seal can allow air to enter the pump, causing a loss of prime and reduced water flow.

- Noisy Operation: A damaged seal may cause the pump to make unusual noises, such as grinding or squealing.

- Frequent Prime Loss: If your pump loses prime more often than usual, it could be due to a faulty shaft seal allowing air into the system.

How Do I Know What Shaft Seal to Use

To select the correct seal, you’ll need to know the make and model of your pump. This information can usually be found on the original pump label or the pump housing.

Once you have identified your pump model, consult a pool pump seal chart or contact the manufacturer for guidance. Major pump brands like Hayward and Pentair offer a variety of seals designed for specific models, such as the Hayward Super Pump or the Pentair Dyna-Max series.

When selecting a seal, consider the materials used in its construction. For demanding applications like saltwater pools, opt for a silicon carbide seal or Viton rubber components, which offer superior resistance to the corrosiveness of salt water. These premium materials can help prevent premature failure and extend the life of your seal.

How Do I Replace a Pool Pump Shaft Seal

- Turn off the power to the pump at the circuit breaker and disconnect any power connections.

- Close the valves on the suction and discharge sides of the pump to prevent water loss.

- Drain the pump housing by removing the drain plug at the bottom of the pump.

- Remove the bolts securing the pump housing to the seal plate and motor using a wrench or socket set.

- Carefully pull the pump housing away from the seal plate, ensuring not to damage the impeller.

- Remove the impeller by turning it counterclockwise. If it’s stuck, gently tap it with a rubber mallet.

- Remove the old shaft seal from the impeller and seal plate. The seal consists of two parts: a rotating part (spring half) and a stationary part (ceramic seat).

- Clean the seal plate and impeller, ensuring they are free from debris and old seal materials.

- Inspect the seal plate, impeller, and pump housing for cracks or damage. Replace if necessary.

- Lubricate the new shaft seal with a seal installation lubricant recommended by the manufacturer.

- Install the new ceramic seat into the seal plate, with the polished surface facing outward. Use a clean cloth to avoid contaminating the seal.

- Install the new spring half onto the impeller, with the black rubber part facing the impeller.

- Reinstall the impeller onto the motor shaft by turning it clockwise until it locks into place.

- Carefully slide the pump housing back onto the seal plate, ensuring the O-ring is properly seated.

- Secure the pump housing to the seal plate and motor using the bolts removed earlier.

- Reconnect any power connections and turn on the power to the pump at the circuit breaker.

- Open the valves on the suction and discharge sides of the pump.

- Prime the pump if necessary and check for any leaks around the pump housing or seal plate.

FAQs

Are All Pool Pump Shaft Seals the Same

No, pool pump shaft seals are not all the same. They vary in size, material, and design depending on the make and model of the pump.

Pool Pump Shaft Seal Replacement Cost

On average, a new seal can cost between $15 and $50, while professional installation may add another $100 to $200 to the total cost.

How Long Does a Pool Pump Shaft Seal Last

On average, a shaft seal can last between 3 to 5 years with proper maintenance and water balance. However, seals in high-stress applications or harsh environments may need to be replaced more frequently.