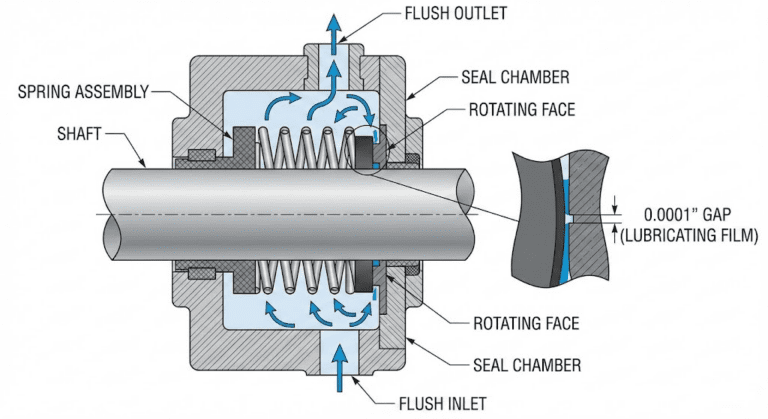

Mechanical seals keep your equipment from leaking. They’re the silent workers in pumps, compressors, and mixers across every industry – from oil and gas to pharmaceuticals to food processing. But here’s the thing: the wrong lubricant destroys these seals in weeks. The right one keeps them running for years.

This guide cuts through the confusion. Whether you’re a technician troubleshooting a failing seal, an engineer selecting fluids for a new system, or a maintenance manager trying to reduce downtime, you’ll learn exactly which oil types work where.

Main Oil Type Categories: A Practical Comparison

The seal lubricant market isn’t one-size-fits-all. You’ve got seven main categories to choose from, each designed for different operating conditions:

| Oil Type | Operating Range | Key Strength | Best For |

|---|---|---|---|

| Mineral (Petroleum) | Standard conditions | Cost-effective, widely available | Budget applications, normal temps |

| Synthetic PAO | -40°C to 150°C | Thermal stability, oxidation resistance | High-temp, extended drain intervals |

| Ester-based | Up to 200°C | Excellent lubricity | Extreme heat, biodegradable options |

| Polyalkylene Glycol (PAG) | High temps | Thermal stability, low volatility | Demanding temperature ranges |

| Perfluorinated Polyether (PFPE) | 270-300°C+ | Exceptional heat/chemical stability | Extreme applications, harsh chemicals |

| Silicone-based | Extreme temps | Thermal stability | Specialized high-temp applications |

| Biodegradable Vegetable | Standard to moderate | Environmental safety | Sensitive industries, environmentally critical |

The choice isn’t just about temperature. You need to consider compatibility with your process fluid, seal materials, regulatory requirements, and total cost of ownership over the seal’s life.

How Do Different Oil Types Perform Under Operating Conditions?

Temperature Performance: Selecting Oil for Your Operating Range

Picking an oil that can handle your equipment’s temperature is non-negotiable. Temperature changes alter fluid viscosity, thermal stability, and ultimately how well your seal stays lubricated.

For normal to moderate temperatures (-40°C to 120°C):

Mineral oils work fine here. They’re cost-effective and do the job. Most routine pump applications fall in this range – water treatment plants, standard chemical processing, pulp and paper operations. The downside? Mineral oils start to struggle when temperatures climb past 120°C.

For moderate to high temperatures (120-150°C):

This is where synthetic PAO oils shine. PAO stands for polyalphaolefin, a synthetically engineered hydrocarbon. PAOs resist thermal breakdown better than mineral oils and maintain better viscosity across temperature swings. If your pump runs hot but not extreme, PAO oils extend drain intervals and reduce oxidation-related degradation. You’ll pay more upfront but recover the investment through fewer fluid changes and longer seal life.

For high temperatures (150-200°C):

Ester-based oils take over here. Diesters and polyolesters provide exceptional thermal stability while maintaining good lubrication properties. The pharmaceutical and food industries often use these because they’re also compatible with demanding elastomers. You’re looking at premium pricing, but in applications where heat is constant, they prevent the catastrophic seal failures that hot mineral oils cause.

For extreme temperatures (above 200°C):

PFPE oils are your only real option. Perfluorinated polyether oils maintain stability between 270°C and 300°C – far beyond what other oils handle. They don’t start breaking down until temperatures exceed 400°C. These fluids are expensive and specialized, but they’re non-negotiable for extreme industrial applications like some specialty chemical reactors or high-temperature industrial compressors.

Thermal Stability and Oxidation Resistance

Here’s where many technicians get burned: choosing an oil based only on its current performance, ignoring how it ages.

Oxidation is your enemy. When oil oxidizes, it thickens, turns dark, and stops protecting your seal faces. As oxidation progresses, varnish deposits form on the seal faces. This buildup creates heat – more heat than your oil can dissipate. The seal face overheats. The process fluid vaporizes at the seal interface. You get catastrophic heat checking and seal failure within days.

Synthetic oils handle oxidation far better than mineral oils. PAO oils, for example, resist oxidation 3-5 times longer than equivalent mineral oils. That’s why PAO-sealed equipment often goes 2-3 years between fluid changes while mineral oil equipment needs changes annually.

Chemical Compatibility and Seal Material Interactions

Your oil can be thermally perfect but completely wrong if it destroys the seal elastomers.

Most mechanical seals use nitrile rubber (NBR) for elastomer components – it’s the industry standard because it’s economical and performs across most applications. But nitrile reacts badly with some oils. Certain synthetic oils swell nitrile, causing seal leaks. Others cause nitrile to shrink and crack.

Temperature compounds this. An oil that plays nicely with nitrile at room temperature might attack it aggressively at 150°C. You need oils specifically tested for elastomer compatibility at your operating temperature.

PTFE (polytetrafluoroethylene) is preferred in specialized applications – pharmaceutical, food processing, chemical manufacturing – because it resists chemical attacks that destroy other seal materials. But PTFE needs different lubricants than nitrile. The lubricity requirements differ. The viscosity needs are different.

Always verify three-point compatibility: oil with elastomer, oil with process fluid, and oil with metal/ceramic seal faces. One incompatibility ruins the entire system.

Practical Selection Guide: Choosing the Right Oil for Your Application

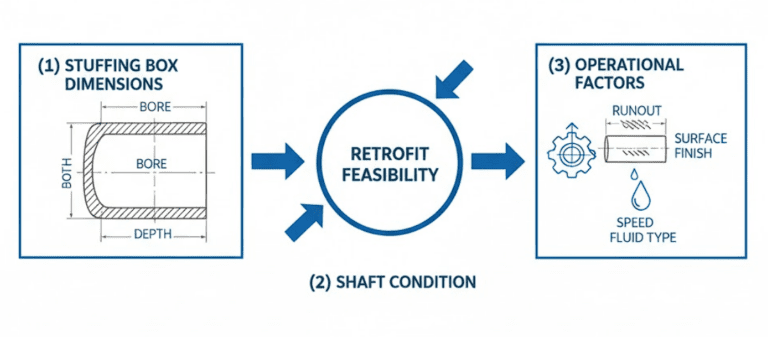

Step 1: Define Your Operating Conditions

Start with the basics. You can’t choose the right oil without understanding exactly what you’re dealing with.

Pressure requirements: Is this a low-pressure seal in a water pump (1-5 bar) or a high-pressure seal in an injection molding machine (100+ bar)? Pressure affects film thickness requirements. High-pressure applications need oils that maintain viscosity and film thickness when compressed.

Temperature range: What’s the minimum and maximum operating temperature? Account for startup temperatures (often much colder) and peak load temperatures. A compressor might idle at 40°C but run at 100°C under full load.

Speed and rotation: How fast is the shaft spinning? RPM affects shear forces on the oil. High-speed seals (above 3000 RPM) need oils that maintain film thickness despite high shear rates. Low-speed seals are more forgiving.

Process fluid characteristics: What are you actually sealing? Is it water (compatible with most oils)? A petroleum product (requires specific compatibility testing)? A caustic chemical (needs PFPE)? The process fluid determines which seal materials work and which oils are compatible.

Step 2: Assess Fluid Compatibility Requirements

Now you’ve defined the conditions. Next comes compatibility – the issue that catches unprepared teams off guard.

Compatibility with process fluid: Some oils mix freely with process fluids. Others separate or create sludge. If your process fluid is water and you choose a standard mineral oil, they’ll emulsify – creating an unstable mixture that damages seals faster than either fluid alone.

Seal material requirements: Check your seal manufacturer’s documentation. They’ll specify compatible fluids for your exact seal model. Don’t assume all PAO oils work with your elastomers – they don’t. Some PAOs swell certain rubbers. Get the compatibility list and stick to it.

System material compatibility: Metal components matter too. Some oils corrode aluminum but not steel. Others create deposits on stainless steel. Your system includes hoses, gaskets, and fasteners made from various materials. The oil must be compatible with all of them.

Step 3: Evaluate Environmental and Regulatory Constraints

Industry regulations increasingly dictate fluid choices. What works on a farm might be illegal at a chemical plant.

Environmental regulations: Some jurisdictions restrict mineral oils in sensitive areas – near waterways, in food processing facilities, in underground applications. Spills of mineral oil trigger environmental cleanup requirements. Biodegradable vegetable oil-based fluids eliminate these regulatory headaches in many cases.

Safety and fire-resistance: Some applications demand fire-resistant fluids. PFPE oils excel here with exceptional thermal stability and fire resistance. HETG (biodegradable vegetable oil) fluids also offer fire-resistant options. This matters critically in power generation plants, aircraft servicing facilities, and other high-risk environments.

Biodegradability requirements: Pharmaceuticals, food processing, and certain chemical applications require biodegradable seal oils. Vegetable oil-based fluids break down rapidly – reducing environmental impact if spills occur.

Step 4: Balance Performance vs. Cost

Finally, the practical reality: initial cost versus total ownership cost.

Initial fluid cost: Mineral oil is cheapest. PAO costs 2-3 times more. Ester oils cost 3-5 times more. PFPE oils can be 10+ times more expensive than mineral oil. If you’re sealing a water pump in a municipal treatment plant, paying premium prices doesn’t make economic sense.

Extended service life benefits: But here’s where synthetics win. A $200 PAO oil that lasts two years beats a $60 mineral oil that lasts six months – you’re paying roughly the same per year while reducing maintenance labor and risk of failure.

Maintenance and replacement frequency: Track your actual fluid change intervals. If you’re changing mineral oil every year and PAO would go two years, the math is straightforward. Factor in technician time (often $50-150 per hour), equipment downtime, and risk of catastrophic failure.

Total cost of ownership: Calculate it honestly. Include fluid cost, labor for changes, downtime costs if it fails, environmental disposal costs (some oils cost extra to dispose), and the cost of unexpected seal failures. Many applications where managers think mineral oil is cheaper actually cost less with synthetics when total ownership is calculated.