API 682 defines mechanical seal requirements for centrifugal and rotary pumps in petroleum, chemical, and gas industries. The standard’s mission: deliver at least three years of uninterrupted service, or 25,000 operating hours, with a maximum emission screening value of 1,000 ppm.

That reliability target sounds straightforward. Achieving it requires navigating a 260-page specification that covers seal types, arrangements, categories, and piping plans. This guide breaks down the four pillars of API 682 and explains the 8-field specification code that most guides completely ignore.

One critical note before we dive in: API 682 is not a general-purpose mechanical seal standard. The specification intentionally excludes large seals, high-pressure applications, mixer and rotary pump seals, outside-mounted configurations, and elastomeric bellows designs. If your application falls outside these boundaries, you need a different reference.

What Is API 682 and Who Needs It?

API 682 establishes minimum requirements for mechanical seals on centrifugal and rotary pumps handling petroleum, heavy chemicals, and gas. The standard covers shaft diameters from 20 mm to 110 mm and works in conjunction with API 610, which specifies the pumps themselves.

The 4th Edition, published in 2014, remains the current version. It introduced several changes from earlier editions, including allowances for mixed seal type configurations and expanded piping plan options.

If you work in refineries, petrochemical plants, gas processing facilities, or offshore platforms, API 682 likely governs your mechanical seal specifications. The standard exists because the petroleum and chemical industries cannot tolerate the downtime and emissions risks associated with premature seal failures.

The petroleum industry developed this standard through a task force of 25 members, including representatives from major oil companies, seal manufacturers, and engineering consultants. Their collective experience shaped requirements that address real-world failure modes rather than theoretical ideals.

Understanding API 682 Seal Categories

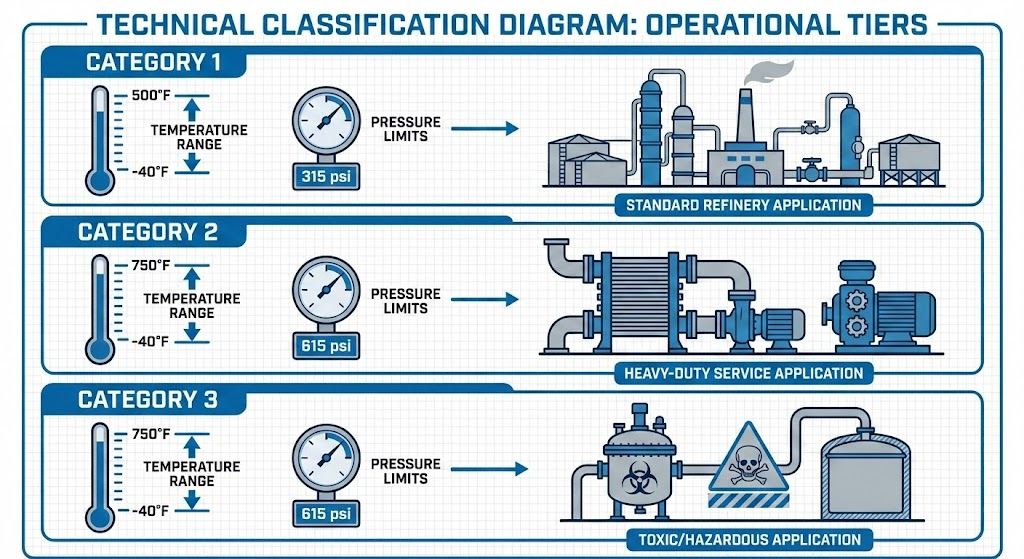

API 682 defines three categories based on operating conditions and seal construction requirements:

| Category | Temperature Range | Pressure Limit | Primary Use |

|---|---|---|---|

| Category 1 | -40 to 500F (-40 to 260C) | 315 psi (22 bar) | Standard refinery service |

| Category 2 | -40 to 750F (-40 to 400C) | 615 psi (42 bar) | Heavy-duty hydrocarbon service |

| Category 3 | -40 to 750F (-40 to 400C) | 615 psi (42 bar) | Toxic/hazardous service |

Category 1 handles most general refinery applications. The seals meet baseline requirements for materials, testing, and documentation.

Category 2 expands the operating envelope to higher temperatures and pressures. These seals require enhanced materials and more rigorous qualification testing. Category 2 is your choice when process conditions exceed Category 1 limits but the fluid presents no special hazards.

Category 3 addresses toxic, hazardous, or otherwise dangerous fluids regardless of temperature and pressure. The category mandates additional design features for emissions control and often requires dual seal arrangements with pressurized barrier fluids.

Selecting the right category starts with your process conditions. If temperature or pressure exceeds Category 1 limits, you need Category 2 or 3. If the fluid poses toxicity or environmental hazards, Category 3 applies regardless of other conditions.

API 682 Seal Types Explained (Type A, B, C)

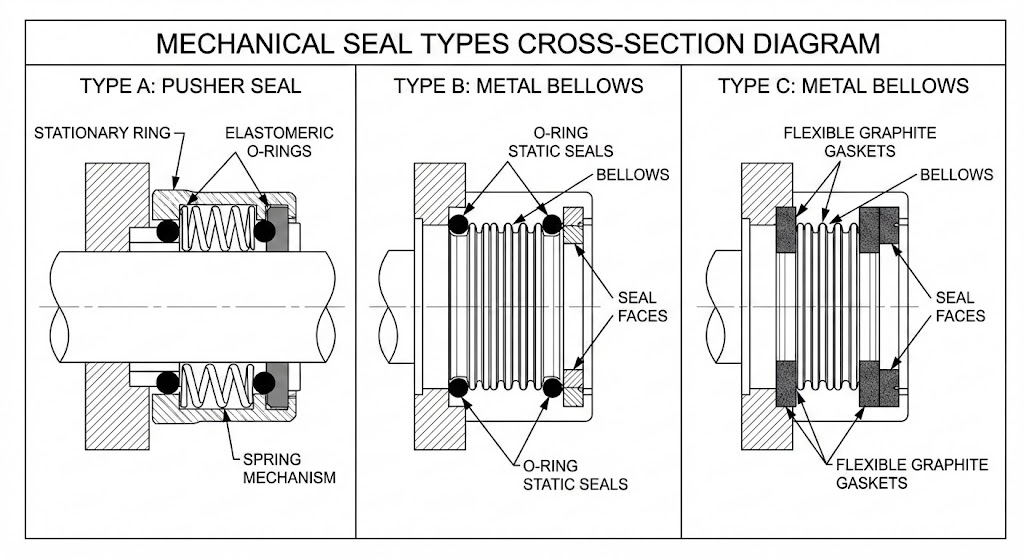

API 682 classifies seals into three types based on their secondary sealing mechanism:

Type A (Pusher Seals) use elastomeric secondary seals such as O-rings and wedges. These seals accommodate axial movement through spring-loaded face contact. Temperature limit: 350F (176C). Type A seals suit general applications where the process fluid is compatible with elastomeric materials.

Type B (Metal Bellows with Elastomers) replace the pusher mechanism with a welded metal bellows while retaining elastomeric O-rings for static sealing. Temperature limit: 350F (176C). The bellows eliminates dynamic O-ring wear, making Type B seals superior for chemically aggressive fluids and cryogenic service.

Type C (High-Temperature Bellows) use metal bellows with flexible graphite gaskets instead of elastomers. Temperature limit: 750F (400C). API 682 restricts Type C seals to Category 2 and 3 applications and requires stationary seal designs as standard.

Speed limits apply to all types. Rotating seal elements have a maximum surface speed of 4,500 ft/min (23 m/s). Stationary elements can operate up to 6,000 ft/min (30 m/s), which is why Type C seals default to stationary configurations.

Temperature limits reflect the weakest component in the seal assembly. For Type A and B seals, that component is the elastomeric O-ring. Even exotic elastomers like FFKM can only reach 316-327C depending on the specific grade. The seal face materials can handle far higher temperatures, but the O-ring sets the system limit.

The 4th Edition introduced an important flexibility: mixed type configurations. A dual seal can now use Type C on the inner (process side) seal and Type A on the outer (atmospheric side) seal. This combination maximizes high-temperature capability where needed while using cost-effective materials where conditions allow.

When selecting seal types, consider both temperature and chemical compatibility. Type B metal bellows seals excel in applications with shaft deflection or where eliminating dynamic O-ring wear improves reliability. For temperatures above 350F, Type C becomes mandatory.

Seal Arrangements in API 682 (1, 2, 3)

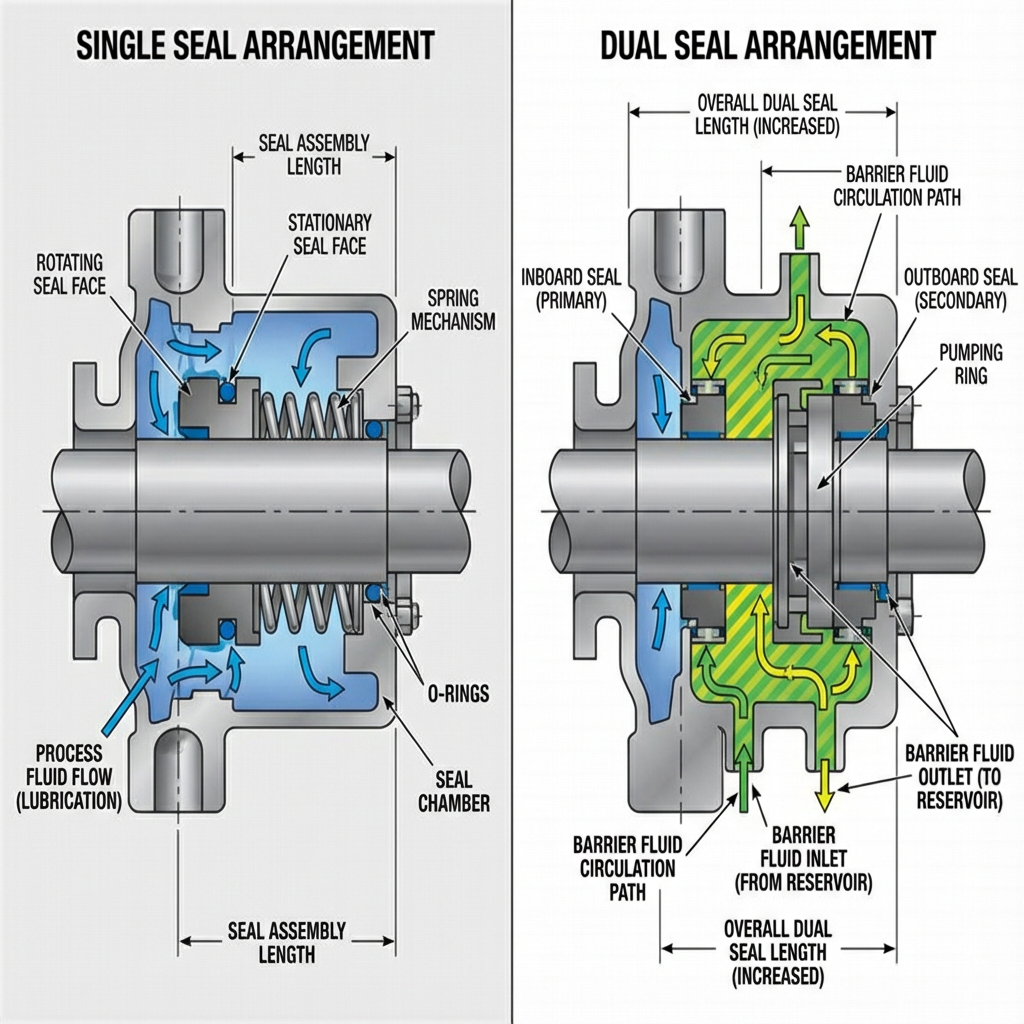

API 682 defines three seal arrangements that differ in how they manage process fluid containment:

Arrangement 1 is a single seal exposed directly to the process fluid. The seal relies on the process fluid for lubrication and cooling. This arrangement suits non-hazardous fluids with adequate lubricity and vapor pressure margin.

Arrangement 2 uses two seals with an unpressurized buffer fluid between them. The inner seal handles the process fluid; the outer seal provides backup containment. The buffer fluid operates at lower pressure than the seal chamber, so any leakage flows from process to buffer.

Arrangement 3 uses two seals with a pressurized barrier fluid between them. The barrier pressure exceeds the seal chamber pressure by at least 25 psi. Any leakage flows from barrier to process and to atmosphere, ensuring zero process fluid emission. This arrangement is mandatory for toxic and hazardous services.

Choosing between single and dual seal arrangements depends on fluid properties and emissions requirements. API 682 provides specific guidance: fluids with specific gravity below 0.5 require Arrangement 3 seals because low-density fluids have insufficient film strength for reliable single-seal operation.

Case Study: NGL Export Pumps

A sour condensate facility installed API 682 dual seals on two NGL export pumps. Despite specification compliance, the seals achieved only 7-month mean time between failures against a 36-month design target.

Root cause analysis revealed multiple contributing factors:

- Pumps operated at 450-900 gal/min versus 1,080 gal/min best efficiency point

- Process temperature reached 260-270F against 246F design specification

- A stuck check valve on the API Plan 76 created 20 psig back pressure (limit: 10 psig)

- Blocked seal vent lines prevented proper stuffing box venting

- Fluid specific gravity of 0.497 (below the 0.5 threshold for reliable sealing)

The facility upgraded to Arrangement 3 with Plan 53B for the critical pumps. The combination of pressurized barrier fluid and proper support system design addressed the root causes.

This case illustrates a pattern I see repeatedly: correct seal selection means nothing without proper installation and support system configuration. The API 682 specification provides the framework, but field execution determines actual reliability.

How to Read the API 682 8-Field Specification Code

The 8-field seal code is the most practical tool in API 682, yet most guides skip it entirely. This alphanumeric string communicates complete seal specifications in a standardized format that suppliers and end users both understand.

The code structure:

[1][2][3]-[4][5][6]-[7][8]

Field 1: Category (1, 2, or 3)

Field 2: Arrangement (1, 2, or 3)

Field 3: Type (A, B, or C)

Field 4: Containment Device

Field 5: Gasket Material

Field 6: Face Material Combination

Field 7: Shaft Size (mm)

Field 8: Piping Plan(s)Field 4: Containment Device Codes

| Code | Description |

|---|---|

| P | Plain bushing |

| L | Floating bushing |

| F | Fixed bushing |

| C | Containment seal (non-contacting) |

| S | Segmented floating bushing |

| X | Unspecified |

Field 5: Gasket Material Codes

| Code | Material |

|---|---|

| F | FKM (Viton) |

| G | PTFE |

| H | Nitrile |

| I | FFKM (Kalrez) |

| R | Flexible graphite |

| X | Unspecified |

Field 6: Face Material Codes

| Code | Combination |

|---|---|

| M | Carbon vs tungsten carbide |

| N | Carbon vs silicon carbide |

| P | Silicon carbide vs silicon carbide |

| Q | Silicon carbide vs tungsten carbide |

| R | Tungsten carbide vs tungsten carbide |

| X | Unspecified |

Worked Example: 21A-LFN-060-11

Breaking down this code:

- 2 = Category 2 (high-temperature/pressure capable)

- 1 = Arrangement 1 (single seal)

- A = Type A (pusher seal with elastomeric secondaries)

- L = Floating bushing containment

- F = FKM (Viton) gaskets

- N = Carbon vs silicon carbide face combination

- 060 = 60 mm shaft diameter

- 11 = Plan 11 (flush from pump discharge)

This code specifies a single pusher seal for Category 2 service, with a floating bushing, Viton elastomers, carbon versus SiC face combination, on a 60 mm shaft, using Plan 11 flush.

Second Example: 31B-LIN-075-53A

- 3 = Category 3 (toxic/hazardous service)

- 1 = Arrangement 1 (single seal)

- B = Type B (metal bellows with elastomeric O-rings)

- L = Floating bushing

- I = FFKM (Kalrez) gaskets

- N = Carbon vs silicon carbide

- 075 = 75 mm shaft diameter

- 53A = Plan 53A (pressurized barrier with accumulator)

Wait – Category 3 with Arrangement 1? This highlights an important point: Category 3 defines the fluid hazard level and documentation requirements, while Arrangement defines the seal configuration. Category 3 single seals exist for applications where dual seals are impractical but enhanced materials and monitoring are required.

When reviewing supplier quotations, the 8-field code tells you immediately whether the proposed seal matches your specification. Any deviation from your required code requires engineering review and approval.

API 682 Piping Plans Selection Guide

Piping plans (also called flush plans or seal support systems) maintain the seal environment within design limits. API 682 defines over 30 standard plans, but a subset handles most applications.

Single Seal Plans (Arrangement 1)

Plan 11 recirculates fluid from the pump discharge to the seal chamber through an orifice. Minimum orifice size: 3 mm (1/8 inch). This plan suits clean, cool fluids and horizontal pump installations.

Plan 13 recirculates from the seal chamber back to pump suction. Use for vertical pumps or when seal chamber pressure exceeds discharge pressure.

Plan 21 cools the recirculated flush with an external heat exchanger. Required when process temperature exceeds seal limits.

Plan 23 uses a thermosyphon system to cool the seal chamber without external piping connections. Temperature threshold: do not use if process temperature is below 60C (140F), as the thermosyphon effect requires adequate temperature differential.

Dual Seal Plans (Arrangement 2 and 3)

Plan 52 provides unpressurized buffer fluid circulation for Arrangement 2 seals. The buffer reservoir operates at atmospheric or low pressure.

Plan 54 delivers externally pressurized barrier fluid for Arrangement 3 seals. A separate pump or pressure source maintains barrier pressure above seal chamber pressure.

Plan 53A uses an accumulator/reservoir system with nitrogen pressurization for Arrangement 3. The bladder accumulator maintains pressure while a cooling loop removes heat.

Plan 53B employs a bladder-type accumulator with direct nitrogen pressurization. This plan suits single-seal applications where multiple seals share one system would be impractical.

Selecting Between Plan 53B and Plan 54

This decision depends on four factors:

| Factor | Plan 53B | Plan 54 |

|---|---|---|

| Temperature | Below 500F | 500-800F |

| Barrier pressure | Up to 200 psi (bladder limit) | Higher pressures possible |

| Heat removal | 8,000-12,000 BTU/HR max | Higher capacity available |

| System sharing | One reservoir per seal | Multiple seals per system |

For most applications below 500F with moderate heat loads, Plan 53B provides simpler installation and lower cost. Above 500F or when heat generation exceeds the bladder system capacity, Plan 54 becomes necessary.

The 4th Edition requires all buffer and barrier fluid reservoirs to hold sufficient volume for at least 28 days of operation without refilling. This requirement ensures continued protection during normal operating cycles.

Quick Selection Guide for Common O&G Applications

The following guidance covers typical scenarios. Always verify against specific process conditions and site requirements.

Standard Refinery Service

| Application | Category | Arrangement | Type | Typical Plan |

|---|---|---|---|---|

| Light hydrocarbon | 1 | 1 | A | 11 |

| Hot oil (>300F) | 2 | 1 | B or C | 21 or 23 |

| High-pressure crude | 2 | 1 | A | 11 |

| Sour service | 3 | 3 | B | 53A or 54 |

NGL and LPG Applications

Low-density fluids (specific gravity below 0.5) require Arrangement 3 with pressurized barrier. Plan 53B or 54 depending on temperature and pressure. Type B seals preferred for cryogenic LPG.

When API Seals Are Not Required

API 682 compliance adds cost through enhanced materials, testing, and documentation. For non-critical services with:

- Non-hazardous fluids

- Low consequence of failure

- Standard temperature and pressure conditions

- Water or other common fluids

Non-API seals may provide adequate reliability at lower cost. The decision requires balancing initial cost against reliability expectations and failure consequences.

Balance Requirements

API 682 specifies hydraulically balanced seals for most applications. Balanced designs reduce face loading and heat generation, extending seal life in high-pressure service. The standard also requires seals to withstand pressure reversals up to 40 psi (2.75 bar).

Where Most API 682 Implementations Fail

The most common failure pattern I encounter: engineers specify the right seal but ignore piping plan execution. A correctly specified Plan 53B with a stuck check valve delivers the same 7-month MTBF as a completely wrong specification.

Start with the 8-field code to define your baseline requirements. Then verify three things before commissioning: barrier fluid pressure matches specification, vent lines are clear, and the pump operates within its efficiency curve. These field checks catch 80% of the issues that turn API 682 compliance into premature failures.