A single mechanical seal uses one set of sealing faces and works best for non-hazardous fluids. A double mechanical seal uses two sets of sealing faces with a barrier or buffer fluid in between, making it the right choice for hazardous, toxic, or difficult-to-seal applications.

This guide will help you understand when to use each type and make the right selection for your application.

How Does a Single Mechanical Seal Work?

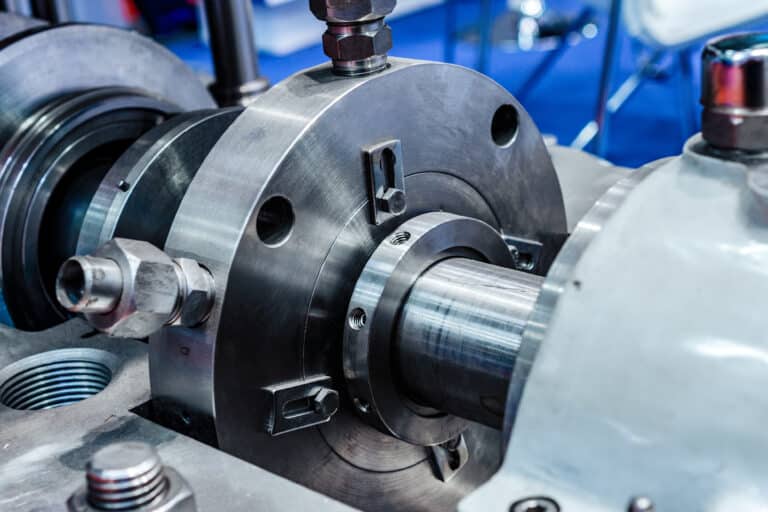

A single mechanical seal creates a barrier between rotating and stationary pump components using two precision-machined flat surfaces pressed together by spring force.

The concept is elegantly simple. You have a rotating element attached to the shaft and a stationary element fixed to the pump casing. These two faces are lapped so flat that the gap between them measures about 1 micron. That’s 75 times narrower than a human hair.

What Are the Key Components of a Single Seal?

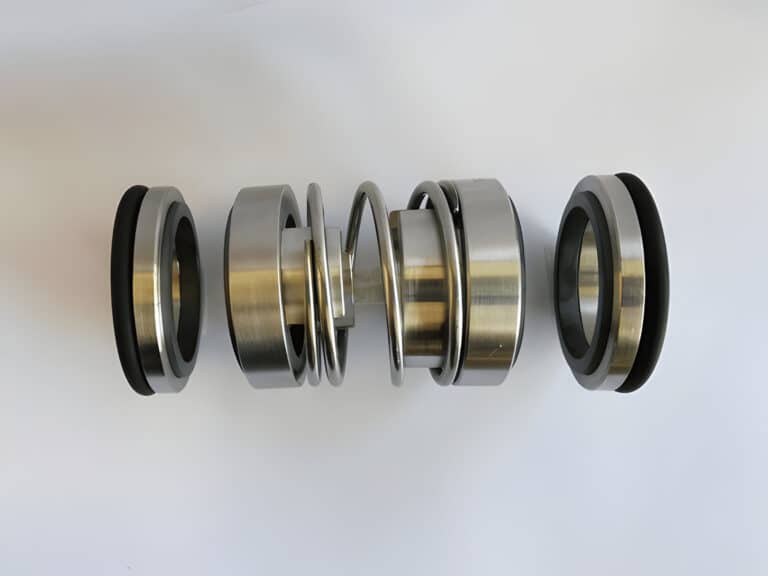

A single mechanical seal has four main components:

- Rotating seal face – Attached to the shaft, this face spins with the impeller

- Stationary seal face – Fixed to the pump housing, this face doesn’t move

- Spring mechanism – Pushes the two faces together to maintain contact

- Secondary seals – O-rings or gaskets that prevent leakage around the primary components

The seal faces are typically made from different materials. You’ll often see a carbon graphite rotating face paired with a silicon carbide or ceramic stationary face. This combination provides good wear resistance and thermal conductivity.

How Does a Double Mechanical Seal Work?

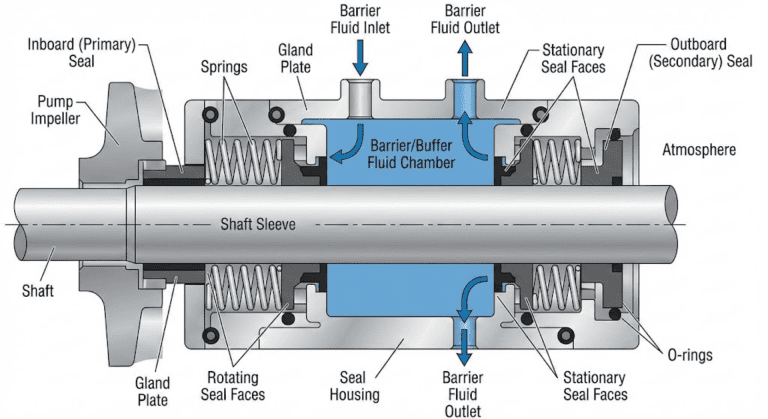

A double mechanical seal arranges two complete seals in series, creating two barriers between the process fluid and the atmosphere.

Think of it as a backup system. The inner seal (called the primary or inboard seal) contains the process fluid within the pump. The outer seal (the secondary or outboard seal) prevents the lubricating fluid from escaping to atmosphere.

This gives you four sealing faces instead of two. Two faces rotate with the shaft while the other two remain stationary. The design concentrates wear on the stationary faces, which helps extend seal life.

What Are the Primary and Secondary Seals?

The primary seal is your first line of defense. It sits closest to the pumped fluid and handles the pressure differential between the process and the space between the seals.

The secondary seal provides the backup. If the primary seal fails or wears, the secondary seal contains any leakage while you plan maintenance. You get warning signs instead of sudden catastrophic failure.

Between these two seals sits a cavity filled with either barrier or buffer fluid. This fluid lubricates both seal faces and can be monitored for contamination, giving you early indication of primary seal problems.

What Is the Role of Barrier and Buffer Fluids?

The fluid between your double seal faces isn’t just sitting there. It’s actively working to keep your seals healthy.

Barrier fluid operates at higher pressure than your process fluid, typically 15-30 psi (1-2 bar) above seal chamber pressure. This pressure differential means if any leakage occurs across the primary seal, clean barrier fluid leaks into the process rather than process fluid leaking out. Chemical plants handling toxic materials often require this setup.

Buffer fluid operates at lower pressure than the process. It provides lubrication and cooling but doesn’t prevent process fluid from crossing the primary seal during upset conditions. This works for applications where small amounts of leakage can be contained and disposed of properly.

What Are the Three Double Seal Configurations?

Double seals come in three arrangements: back-to-back, tandem, and face-to-face. Each has specific advantages depending on your application.

| Configuration | Seal Orientation | Best Application | Fluid Requirement |

|---|---|---|---|

| Back-to-Back | Faces point away from each other | Hazardous chemicals | Pressurized barrier fluid |

| Tandem | Both seals face same direction | Backup protection | Buffer fluid (lower pressure) |

| Face-to-Face | Faces point toward each other | Space-constrained equipment | Either barrier or buffer |

Back-to-Back Configuration

Back-to-back is the most popular arrangement for hazardous services. The two rotating seal rings face opposite directions, with the barrier fluid chamber between them.

This configuration requires pressurized barrier fluid to function properly. The barrier fluid acts as a lubricant and creates positive pressure that pushes against both seal faces. If either seal develops a problem, barrier fluid leaks first, giving you time to respond.

Chemical processing plants handling dangerous materials favor back-to-back seals because they prevent any process fluid from reaching atmosphere under normal operation.

Tandem (Face-to-Back) Configuration

Tandem seals orient both seal sets in the same direction, creating a true series arrangement. The primary seal handles the process pressure while the secondary seal operates at near-atmospheric conditions.

This configuration works with buffer fluid at lower pressure than the process. If the primary seal fails, the secondary seal takes over completely. You get absolute backup protection.

I prefer tandem seals when the goal is extended run time rather than zero emissions. They’re slightly simpler than back-to-back arrangements and give you genuine redundancy.

Face-to-Face Configuration

Face-to-face seals put both seal faces pointing toward each other, sharing a common stationary component. This creates the most compact double seal arrangement.

The compact design saves axial space, making face-to-face seals useful when equipment design limits installation room. Food processing applications sometimes use this configuration.

The downside? If that shared stationary component breaks, both seals fail simultaneously. You lose the redundancy benefit that makes double seals valuable. I recommend other configurations when space permits.

When Should You Use a Single Mechanical Seal?

Single seals are your default choice for straightforward applications. They cost less, install easier, and require simpler support systems.

Use a single seal when your pumped fluid is non-hazardous and poses minimal environmental risk. Clean water, cooling tower circulation, and general process water services are perfect candidates.

What Fluid Properties Favor Single Seals?

Single seals work best with fluids that have good lubricating properties and won’t damage the seal if small amounts escape. Consider these characteristics:

- Non-toxic and non-hazardous – The fluid won’t cause harm if trace amounts leak to atmosphere

- Good lubricity – The fluid creates an adequate film between seal faces

- Non-corrosive to seal materials – Common elastomers and face materials handle the fluid well

- Clean and free of solids – Particles won’t damage the precision-lapped faces

- Moderate temperature – The fluid stays liquid and doesn’t vaporize at seal faces

Water, light oils, and many glycol solutions fit these criteria perfectly.

What Operating Conditions Are Ideal for Single Seals?

Beyond fluid properties, your operating conditions matter for single seal selection:

- Low to moderate pressure – Standard single seals handle most pump discharge pressures

- Temperatures below 350°F (177°C) – Higher temperatures may require special materials or cooling

- Stable operation – The pump runs near its best efficiency point without frequent upsets

- Minimal environmental concern – Small leakage rates are acceptable

- Cost-sensitive applications – Budget constraints favor simpler solutions

Single seals handle the majority of industrial pumping applications. About 88% of process centrifugal pumps use them, which tells you they work well for most services.

When Should You Use a Double Mechanical Seal?

Double seals become necessary when single seals can’t provide adequate safety, environmental protection, or reliability for your application.

The extra cost and complexity make sense when fluid characteristics or regulatory requirements demand zero emissions, when seal failure creates serious safety hazards, or when the process fluid damages seal faces.

What Applications Require Double Seals?

These situations typically require double seal arrangements:

- Toxic or hazardous chemicals – Ammonia, chlorine, hydrogen sulfide, and similar materials that can’t leak to atmosphere

- Volatile organic compounds (VOCs) – Regulations often mandate zero-emission sealing

- Flammable liquids – Fire safety requires containing potential ignition sources

- Expensive products – Pharmaceutical ingredients or specialty chemicals where even small losses matter

- Abrasive slurries – Buffer fluid protects seal faces from particle damage

- Polymerizing fluids – Materials that solidify or create deposits need barrier fluid flushing

- High-temperature services – External cooling through barrier circulation extends seal life

I’ve worked with plants that standardized on double seals across entire process units handling hazardous materials. The consistency simplifies training and maintenance procedures.

What Safety and Regulatory Factors Demand Double Seals?

Regulations increasingly drive double seal requirements. The API 682 standard’s fourth edition now considers fluid toxicity using the UN Globally Harmonized System (GHS) classification when recommending seal arrangements.

Consider double seals when:

- Emissions regulations apply – EPA, OSHA, or local air quality rules may mandate containment

- Worker safety is paramount – Exposure limits on process chemicals require secondary containment

- Process contamination risks exist – Pharmaceutical and food industries can’t tolerate atmospheric contamination entering products

- Insurance requirements specify them – Some underwriters require double seals for certain chemical services

- Company standards mandate them – Many corporations have internal policies stricter than regulations

The double seal gives you a monitored leak path. When the primary seal starts to fail, barrier or buffer fluid shows contamination before process fluid reaches atmosphere. That early warning is valuable.

How Do Single and Double Seals Compare in Key Performance Areas?

The choice between single and double seals involves tradeoffs in cost, reliability, and complexity. Understanding these differences helps you make informed decisions.

Cost Comparison: Upfront vs. Long-Term

Single seals cost less initially but may cost more over time in demanding applications.

| Cost Factor | Single Seal | Double Seal |

|---|---|---|

| Initial purchase | Lower ($200-2,000 typical) | Higher ($1,000-10,000+) |

| Support system | Simple flush piping | Reservoir, piping, instrumentation |

| Installation labor | 1-2 hours typical | 2-4 hours typical |

| Spare parts inventory | Minimal | Larger inventory needed |

| Barrier/buffer fluid | None required | Ongoing consumable cost |

The total cost picture changes when you factor in failure consequences. A single seal failure on hazardous service can cost tens of thousands in cleanup, fines, and production losses. Double seals prevent those scenarios.

For demanding applications, plants achieving 3+ years mean time between repairs with double seals often see lower total cost of ownership than those replacing single seals annually.

Reliability and Maintenance Requirements

Double seals offer higher reliability in challenging services, but they require more attention.

Single seals are simpler to maintain. When they fail, replacement is straightforward. The downside is that failure often means immediate leakage. You have no warning and no backup.

Double seals demand regular monitoring. You need to check barrier or buffer fluid levels, watch for pressure changes that indicate seal wear, and maintain auxiliary equipment. This ongoing attention catches problems early.

Installation Complexity

Single seals install quickly if you follow basic procedures. Clean surfaces, proper alignment, and correct setting height are the main concerns.

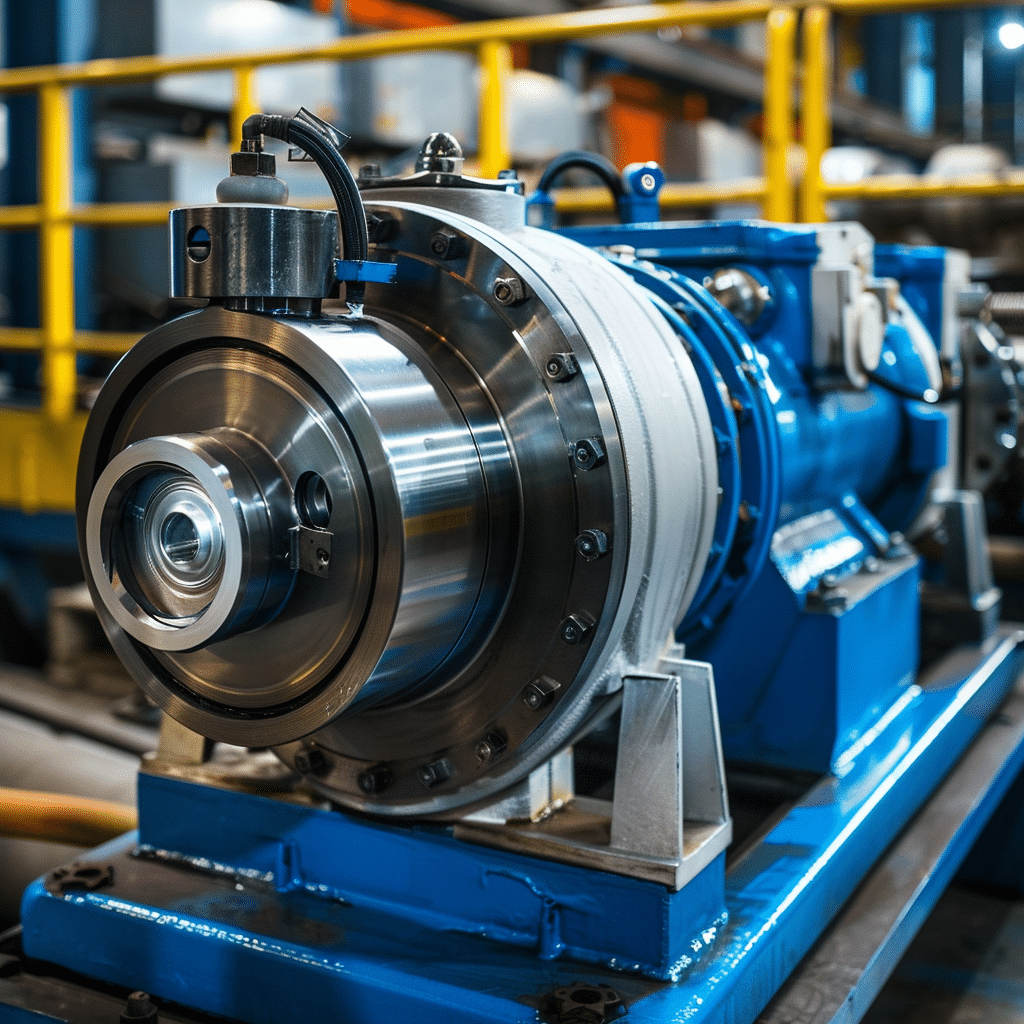

Double seals require more care. You’re installing twice as many precision components, connecting auxiliary systems, and ensuring proper venting. The barrier fluid system needs commissioning before startup.

Conclusion

Selecting between single and double mechanical seals comes down to three factors: fluid hazard level, operating conditions, and total cost of ownership.

Use single seals for non-hazardous fluids in standard operating conditions. They’re simpler, cheaper, and handle the majority of industrial pumping applications successfully.

Switch to double seals when you’re handling hazardous materials, when regulations require zero emissions, or when the process fluid can’t adequately lubricate seal faces. The extra cost buys you safety, regulatory compliance, and early warning of seal problems.