Industrial pumps handle some of the nastiest, most hazardous fluids on the planet. Toxic gases. Expensive chemicals. Media that crystallizes on contact. When these fluids leak, the consequences aren’t just expensive—they’re dangerous.

That’s where double mechanical seals come in.

A double mechanical seal uses two sets of sealing faces working together to create a dual-barrier system. Between those two seals sits either a barrier fluid or buffer fluid, depending on the arrangement. This setup stops hazardous materials from reaching the atmosphere and helps equipment operators comply with strict environmental regulations like EPA LDAR (Leak Detection and Repair).

The real power of double seals is that they provide redundancy. If one seal fails, the other remains intact, keeping your process contained until you can schedule maintenance.

But here’s the thing: not all double seals work the same way. Three primary arrangements—back-to-back, tandem, and face-to-face—each have distinct operating principles, pressure requirements, and real-world advantages.

Back-to-Back Double Seals: Pressurized Dual Defense

Back-to-back double seals are the most common arrangement in general industrial applications. They’re compact, cost-effective, and handle a wide range of conditions. But they require a pressurized system to operate correctly.

How Back-to-Back Seals Work

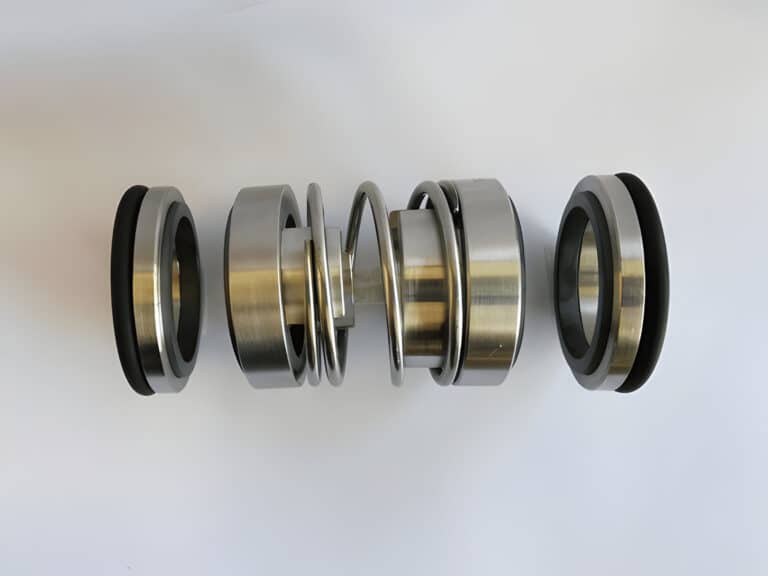

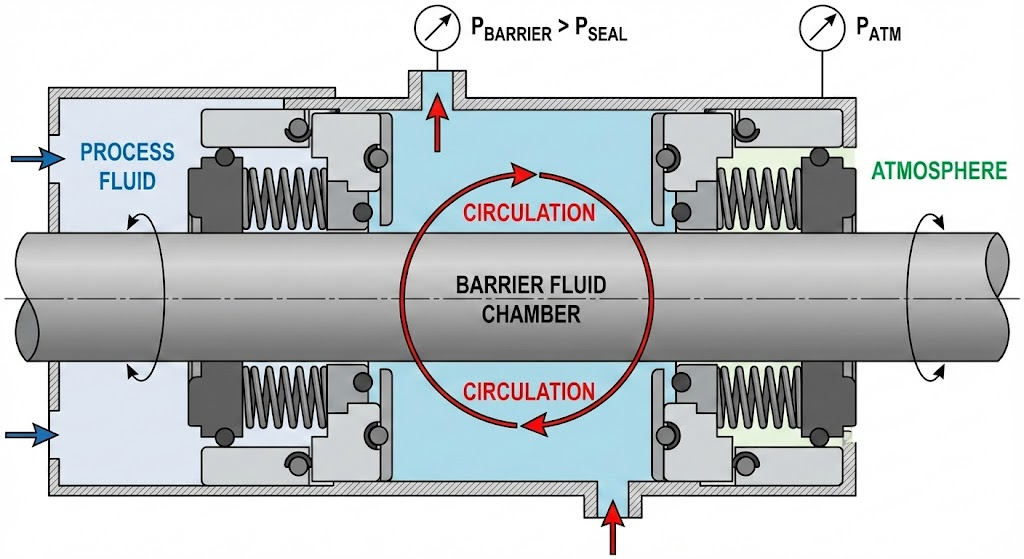

The two mechanical seal pairs facing each other in opposite orientations. The inboard seal faces the process fluid you’re sealing. The outboard seal faces the atmosphere. Between them sits a pressurized barrier fluid.

The barrier fluid does the heavy lifting. Its pressure is maintained 10 to 15 percent higher than the seal chamber pressure—typically a minimum of 2 to 3 bar above stuffing box pressure. This pressure pushes the seal faces together, ensuring they create a tight seal against their mating rings.

When the seal operates correctly, any leakage from the inboard seal crosses into the barrier fluid chamber, where it’s contained. The barrier fluid circulates through a support system (following API 682 flush plans), keeping the seal faces cool and lubricated. This circulation is critical. Without it, the seal faces overheat and fail within minutes.

Balanced vs. Unbalanced Back-to-Back Designs

Back-to-back seals come in two balance ratios, and this distinction matters for pressure and heat considerations.

Unbalanced back-to-back seals have a balance ratio above 100 percent, typically 110 to 160 percent. More of the seal ring area is exposed to hydraulic pressure, creating a higher closing force. This extra force makes unbalanced seals more resistant to vibration and cavitation, but it also generates more heat. Unbalanced designs require barrier fluid pressure 15 psig higher than seal chamber pressure and work best in lower-pressure applications.

Balanced back-to-back seals have a balance ratio between 60 and 90 percent. The seal design reduces hydraulic pressure acting on the seal faces, lowering the closing force. Less closing force means less heat generation, lower face wear, and better lubrication film formation. Balanced seals excel in high-pressure applications and handle non-self-lubricating fluids better than their unbalanced counterparts. They can even operate with buffer fluid instead of barrier fluid if the application permits.

If you’re running high temperature or aggressive chemicals, balanced seals keep your system running cooler and longer.

Tandem Double Seals: Series Redundancy with Buffer Pressure

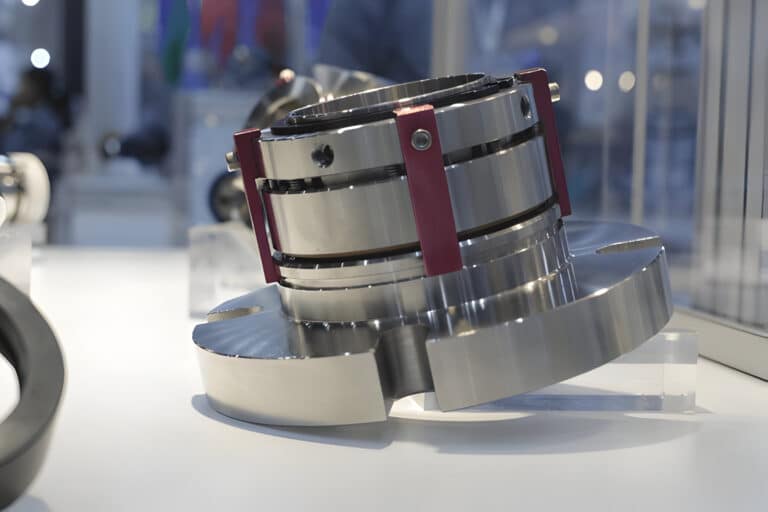

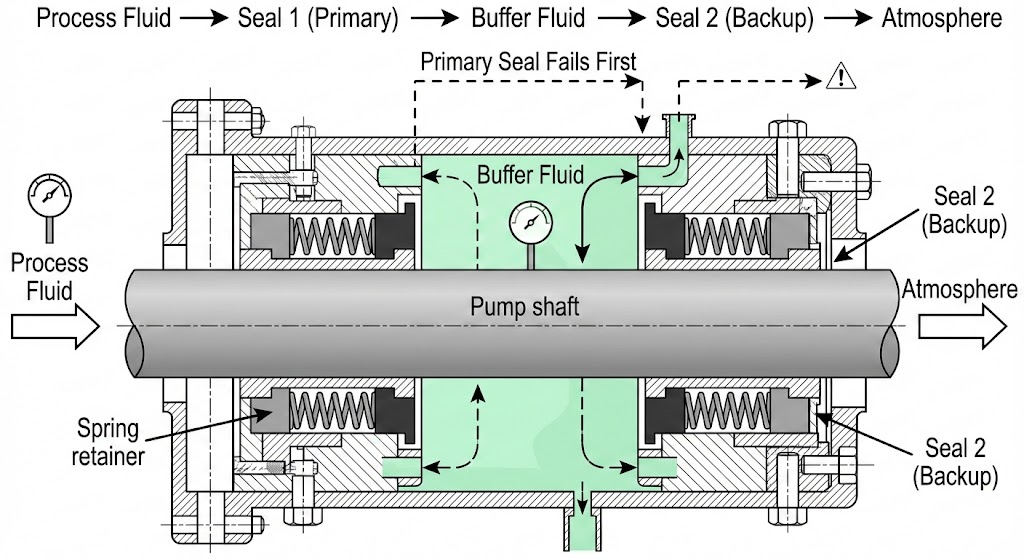

Tandem seals represent a fundamentally different approach. Instead of working in opposition, the two seal pairs are mounted identically in series—one behind the other along the shaft. This arrangement is sometimes called “in-series” or “face-to-back” configuration, and it’s the choice for the most hazardous applications.

How Tandem Seals Operate

In a tandem arrangement, the inboard seal (the one contacting the process fluid) is your primary seal. If it fails, the outboard seal immediately becomes the primary seal, providing automatic redundancy without operator intervention.

The key to tandem operation is buffer fluid—a lower-pressure fluid filling the chamber between the two seals. Buffer pressure is maintained below process fluid pressure. This pressure difference is crucial: if the inboard seal fails and process fluid enters the buffer chamber, the outboard seal remains sealed because it’s still exposed to the lower buffer pressure on one side.

The beauty of this design is cleanliness. Because buffer fluid pressure is lower than process pressure, process fluid naturally flows away from the inboard seal if it leaks. The buffer chamber stays contaminated-free, preserving the cleanliness of your backup seal.

Face-to-Face Double Seals: The Space-Constrained Solution

Face-to-face seals are the least common of the three arrangements, but they solve a specific, real problem: what do you do when you need double seal protection but have virtually no axial space available?

In a face-to-face arrangement, part of the seal assembly sits inside the pump chamber and part sits outside. The design varies, but generally, one pair of seal faces occupies the traditional inside location while the second pair extends outside. This creative arrangement minimizes axial length compared to back-to-back configurations.

Face-to-face seals can function as either pressurized (barrier fluid) or unpressurized systems, depending on engineering requirements. Because they’re less common, they require more careful design and engineering to prevent external exposure and environmental contamination.

Most face-to-face applications are retrofits on existing equipment. A plant inherits an old pump with limited shaft space, needs to upgrade it to double seal protection to meet environmental regulations, and discovers that neither back-to-back nor tandem seals physically fit. Face-to-face becomes the solution.

If you have extreme space constraints and can’t modify the pump housing, face-to-face seals deserve engineering evaluation. But for greenfield applications, back-to-back or tandem arrangements usually make more sense from a reliability and maintainability perspective.

Selecting the Right Double Seal for Your Application: A Decision Framework

Choosing between back-to-back and tandem arrangements requires systematic thinking about your specific conditions. Here’s how experienced engineers approach this decision:

Step 1: Assess Hazard Level

Start with the fundamental question: what are you pumping, and what happens if it leaks?

Non-hazardous fluids like clean water or mineral oils at moderate temperatures and pressures? Back-to-back seals are probably sufficient. The payoff of tandem’s superior reliability isn’t worth the added complexity and cost.

But toxic gases like vinyl chloride? Light hydrocarbons that vaporize instantly? Carcinogenic chemicals requiring zero environmental release? These demand tandem seals. The regulatory and liability risks make the extra cost trivial compared to the cost of environmental cleanup or worker illness.

Step 2: Evaluate Space Constraints

How much axial length do you have available along the pump shaft?

Severely limited space? Back-to-back wins. These seals are compact and fit where tandem arrangements won’t.

Moderate or ample space? Tandem becomes feasible and desirable for hazardous applications.

Step 3: Consider Operating Conditions

Temperature, pressure, and fluid properties dramatically affect arrangement selection.

High temperatures above 200°C? Back-to-back seals leverage leakage for cooling, making them excellent for this scenario. Tandem seals still work but don’t offer the same thermal advantage.

High viscosity media that tends to crystallize? Tandem seals with their passive buffer fluid prevent crystal formation and deposit buildup.

Extreme pressures exceeding 100 bar? Tandem seals generally provide superior reliability under these conditions.

Variable operating conditions with occasional dry running or cavitation? Tandem seals maintain lubrication even during upset conditions. Back-to-back seals struggle when circulation is interrupted.

Step 4: Analyze Support System Capabilities

What infrastructure does your facility already have?

Many refineries and chemical plants already operate pressurized barrier fluid systems for existing back-to-back seals. Installing additional back-to-back seals is straightforward—you just tap into existing support systems.

Installing tandem seals might require new buffer systems, additional monitoring, and different maintenance protocols. This can mean significant capital investment and operator training.

Step 5: Balance Cost Against Reliability

Cost-conscious applications with non-hazardous media and moderate operating conditions? Back-to-back with unbalanced seals provides solid protection at lower cost.

Critical applications where seal failure has serious consequences? Tandem seals with balanced designs justify the higher cost and complexity.

Final Guidance: Making Your Selection

Double mechanical seal arrangements represent a mature technology with decades of field experience. The arrangement you select depends fundamentally on these factors:

Choose back-to-back seals if:

- Your application has space constraints

- You’re pumping high-temperature media where cooling matters

- Your facility already has pressurized barrier fluid support systems

- Cost is a significant factor but hazardous media containment is required

Choose tandem seals if:

- You’re sealing toxic, volatile, or hazardous fluids requiring zero visible leakage

- Operating conditions are extreme (very high pressure, high temperature, or difficult media)

- Your application demands maximum reliability and automatic redundancy

- Preventing crystallization and deposits is critical

Choose face-to-face seals only if:

- Axial space constraints make back-to-back and tandem physically impossible

- You’re retrofitting existing equipment with limited modification capability

By understanding how each arrangement operates, how their pressure systems work, and where they excel in real-world conditions, you’ll select the seal that keeps your process running safely, reliably, and in compliance with environmental regulations.