A single seal failure can shut down your entire production line. I’ve seen procurement teams scramble to find emergency replacements while their plant loses $10,000 per hour in downtime. The frustrating part? Most of these failures were preventable with the right seal selection upfront.

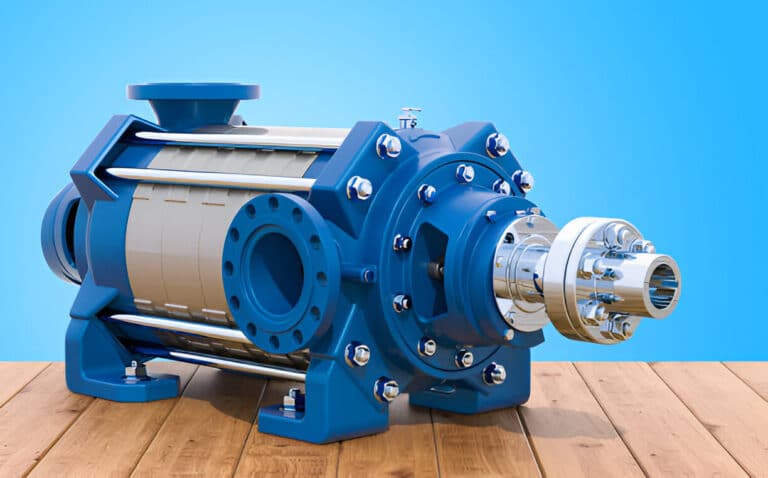

Agitator mechanical seals come in five main types: single mechanical seals, double mechanical seals, cartridge seals, dry gas seals, and lip seals. Each serves different applications, and picking the wrong one costs you more than just the purchase price. You’re paying for installation labor, potential failures, downtime, and replacement parts.

What Are the Main Types of Agitator Mechanical Seals?

Agitator mechanical seals fall into distinct categories based on their design and operating principle. Here’s how they compare:

| Seal Type | Best For | Pressure Range | Relative Cost | Key Advantage |

|---|---|---|---|---|

| Single Mechanical | Non-hazardous fluids | Up to 25 bar | $ | Simple, reliable |

| Double Mechanical | Hazardous/toxic fluids | 30+ bar | $$$ | Zero emissions |

| Cartridge | High-reliability needs | Up to 25 bar | $$ | Easy installation |

| Dry Gas | Pharmaceutical/food | Varies | $$ | No contamination |

| Lip Seal | Low-pressure applications | Up to 10 bar | $ | Budget-friendly |

Single vs. Double Mechanical Seals: Which Do You Need?

Single mechanical seals use one set of sealing faces and work perfectly fine for water, oils, and other non-hazardous process fluids. They cost less upfront and handle most standard mixing applications. I recommend them when you’re not dealing with toxic chemicals or strict emissions regulations.

Double mechanical seals are a different story. They have two sets of sealing faces with a barrier fluid running between them. If the primary seal fails, the secondary seal kicks in as backup. This design eliminates virtually all leakage, which is why chemical plants, pharmaceutical manufacturers, and petroleum refiners require them for hazardous materials.

Here’s my rule of thumb: if a spill would trigger an EPA report, OSHA investigation, or production recall, you need double seals. The extra $500-2,000 per seal is cheap insurance against a $50,000 cleanup.

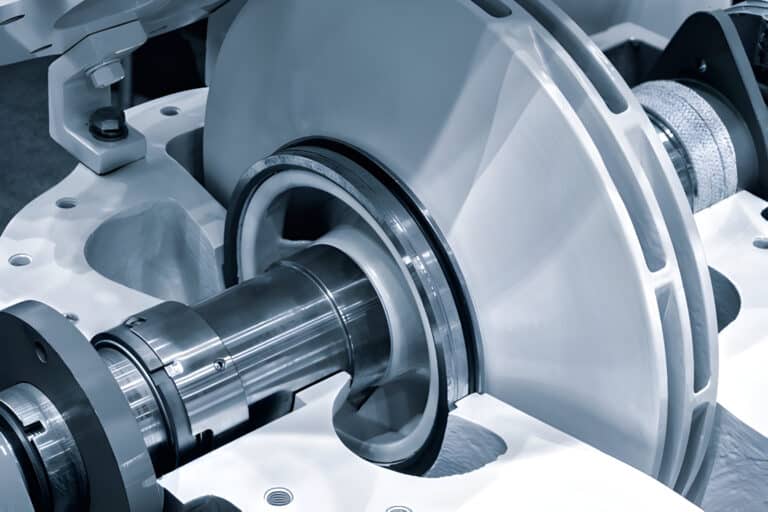

What Makes Cartridge Seals Different from Component Seals?

Cartridge seals arrive pre-assembled and pre-adjusted. You slide them onto the shaft and bolt them down. That’s it. No measuring, no adjusting spring tension, no aligning seal faces by hand.

This matters more than most buyers realize. Industry data shows that 50% of component seal failures trace back to installation errors. Someone over-tightened the gland bolts. Someone touched the seal faces with oily fingers. Someone forgot to remove the setting clips before startup.

Cartridge seals eliminate these problems. Yes, they cost more upfront. But when you factor in reduced installation labor and the lower failure rate, they often pay for themselves within the first year.

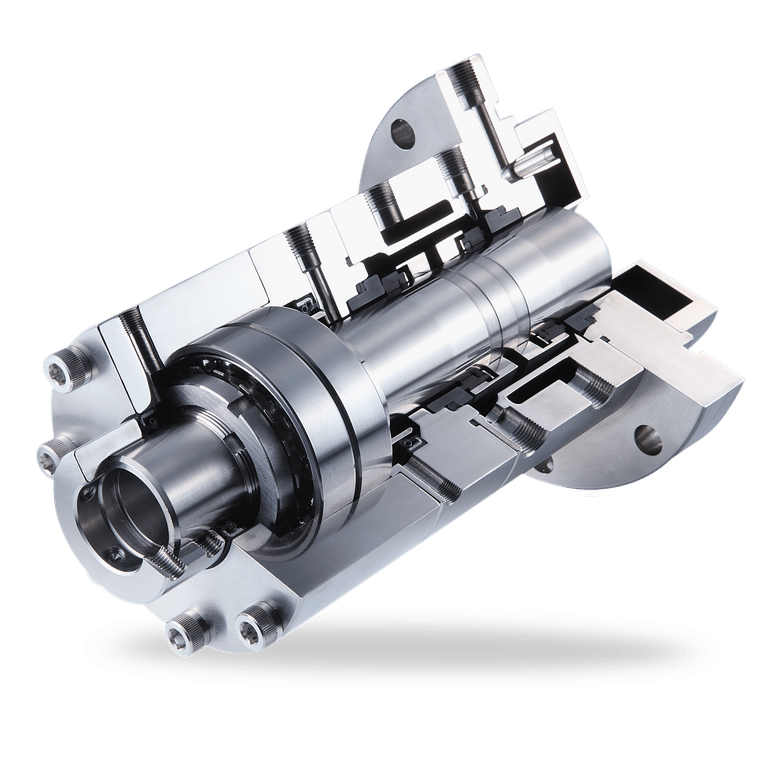

When Should You Consider Dry Gas Seals?

Dry gas seals use pressurized nitrogen instead of liquid barrier fluid between the seal faces. This creates a thin, non-contacting gas film that prevents leakage without any liquid contamination risk.

Pharmaceutical and food-grade applications love these seals. There’s no barrier liquid that could leak into the product batch. The faces don’t physically touch during operation, so you don’t generate carbon particles that could contaminate sensitive formulations.

The trade-off? You need a reliable nitrogen supply and daily monitoring of gas consumption. When consumption spikes, it’s an early warning sign that the seal needs attention.

How Do Entry Configurations Affect Your Seal Choice?

The way your agitator mounts to the vessel determines which seal configuration you need. Each entry point comes with its own challenges.

| Entry Type | Common Applications | Main Challenge | Maintenance Access |

|---|---|---|---|

| Top Entry | Reactors, mixers | Highest shaft runout | Excellent |

| Side Entry | Storage tanks, fuel blending | Excessive runout | Moderate |

| Bottom Entry | Fermenters, bioreactors | Solids accumulation | Limited |

Top Entry Seals

Top entry seals sit at the top of your vessel, making them the easiest to access for maintenance. You can inspect, adjust, or replace them without draining the tank or removing the impeller.

But here’s the catch: top entry configurations create the most shaft runout. The agitator shaft hangs down into the vessel, and that long lever arm wobbles during operation. Standard pump seals expect runout of 0.002 inches or less. Top entry mixers routinely see 0.03 to 0.150 inches. That’s 15 to 75 times more movement than a typical pump.

If you’re specifying seals for a top entry agitator, you absolutely must choose seals designed for mixer applications. Standard pump seals will fail within weeks.

Side Entry Seals

Side entry seals mount on the vessel wall, typically for large storage tanks and fuel blending operations. They’re practical when top access isn’t available or when the vessel is too tall for a top-mounted drive.

Excessive runout remains the primary challenge. The horizontal shaft orientation creates different stress patterns than vertical installations, and many facilities underestimate the alignment precision required.

Bottom Entry Seals

Bottom entry seals work well for fermenters, bioreactors, and applications where minimizing the seal’s exposure to process fluid is important. The compact design keeps the seal out of the main mixing zone.

The downside? Solids tend to accumulate around bottom-mounted seals. Fermentation processes are particularly problematic, as yeast and other materials settle and pack around the seal area. Plan for more frequent cleaning and inspection cycles.

Choosing the Right Seal for Your Application

Match your seal type to your application requirements. Single seals for non-hazardous fluids, double seals for anything toxic or environmentally sensitive, cartridge designs for reliability, and dry gas seals for contamination-free operations.

Don’t buy on purchase price alone. That cheap component seal may cost you three times as much in installation labor and failure-related downtime. Cartridge seals and properly specified mixer seals pay for themselves through reduced failures and faster installation.

When you request quotes, specify your operating conditions: pressure, temperature, shaft speed, fluid properties, and vessel entry configuration. Suppliers who ask follow-up questions about your application are usually the ones worth working with. Those who just quote the cheapest option won’t be there when you need technical support.